- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm, other

-

Place of Origin:

-

henan

-

Brand Name:

-

xindas

-

Voltage:

-

220V,380v

-

Dimension(L*W*H):

-

8500*1600*2500

-

Weight (KG):

-

3500 kg

-

Raw material:

-

Cement

-

Block Type:

-

Hollow Brock

-

Color:

-

Customer's Demand

-

Products:

-

Produce Hollow

-

Weight:

-

3500kg

-

Molding cycle:

-

20-30s

-

Pallet size:

-

680*535*30mm

-

Name:

-

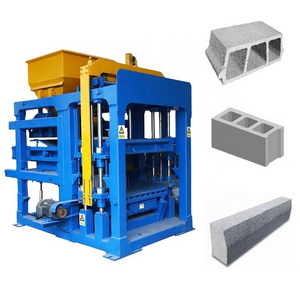

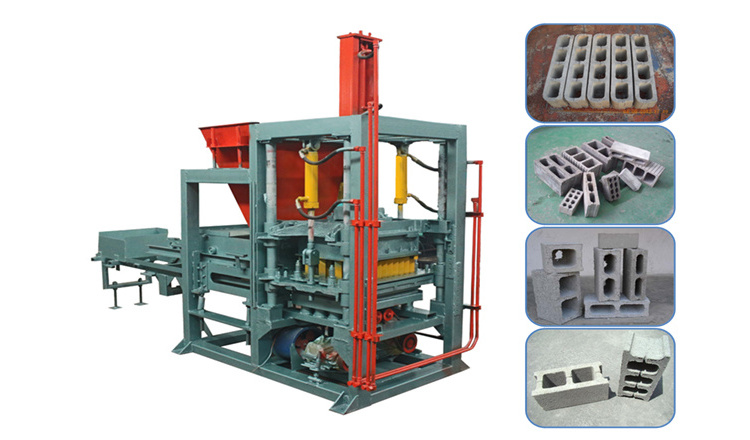

Concrete fly ash brick making machine

-

Product Name:

-

Colorful paver brick machine

-

Keywords:

-

Top performance 1 year warranty

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other, cutting machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours, power

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm, other

-

Place of Origin:

-

henan

-

Brand Name:

-

xindas

-

Voltage:

-

220V,380v

-

Dimension(L*W*H):

-

8500*1600*2500

-

Weight (KG):

-

3500 kg

-

Raw material:

-

Cement

-

Block Type:

-

Hollow Brock

-

Color:

-

Customer's Demand

-

Products:

-

Produce Hollow

-

Weight:

-

3500kg

-

Molding cycle:

-

20-30s

-

Pallet size:

-

680*535*30mm

-

Name:

-

Concrete fly ash brick making machine

-

Product Name:

-

Colorful paver brick machine

-

Keywords:

-

Top performance 1 year warranty

Product Description

Specification

|

item

|

value

|

|

Core Components

|

Gear, Pump

|

|

Raw material

|

Cement

|

|

Block Type

|

Hollow Brock

|

|

Color

|

Customer's Demand

|

|

Products

|

Produce Hollow

|

|

Weight

|

3500kg

|

|

Molding cycle

|

20-30s

|

|

Pallet size

|

680*535*30mm

|

|

Name

|

Concrete fly ash brick making machine

|

|

Product Name

|

Colorful paver brick machine

|

|

Keywords

|

Top performance 1 year warranty

|

Finished production

RAW MATERIAL

Most of the raw materials for burning-free bricks are slag, slag, sand, tailings sand, stone powder, water slag, coal gangue, fly ash, construction waste, etc.,

Burning-free bricks not only turn waste into treasure, but also improve the environment, save resources, and realize the recycling of resources.

Finished product

The main production is standard bricks, Dutch bricks, porous bricks, hollow bricks, pavement bricks, curbs and so on.

One machine is multi-purpose, and different types of bricks can be produced by replacing molds.

Mold display

1.The cement brick mold is composed of an upper extrusion mold and a lower molding module,

It is formed by squeezing and vibrating the upper and lower molds.

2.Different steels are used in different parts of the brick machine mold.

3.According to different requirements, different heat treatment methods (carburizing technology and quenching technology) are used.

4.Processed by wire cutting method,Make the mold size more accurate, and the appearance of the bricks made is flat.

5.The comprehensive heat treatment process makes the brick machine mold more resistant to wear and durable.

Packing & Delivery

Wooden box or nude packing for secondary pressure cement block concrete automatic large production good brick making machine for paving.

Hot Searches