- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Ainuok

-

Item:

-

mushroom batch compost substrate material soil spiral mixer

-

Electricity:

-

3 phase electricity

-

Capacity:

-

300 kg per mix

-

Material:

-

Carbon steel

-

After-sales Service Provided:

-

Online support

-

Application:

-

Mushroom farm

-

Packing dimension:

-

240*115*136 cm

-

Power:

-

5.5 kw

-

Volume:

-

1.6 cubic

-

Packing weight:

-

750 kg

Quick Details

-

Weight (KG):

-

750

-

Type:

-

mixing machine

-

Use:

-

Mixing materials of mushroom

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Ainuok

-

Item:

-

mushroom batch compost substrate material soil spiral mixer

-

Electricity:

-

3 phase electricity

-

Capacity:

-

300 kg per mix

-

Material:

-

Carbon steel

-

After-sales Service Provided:

-

Online support

-

Application:

-

Mushroom farm

-

Packing dimension:

-

240*115*136 cm

-

Power:

-

5.5 kw

-

Volume:

-

1.6 cubic

-

Packing weight:

-

750 kg

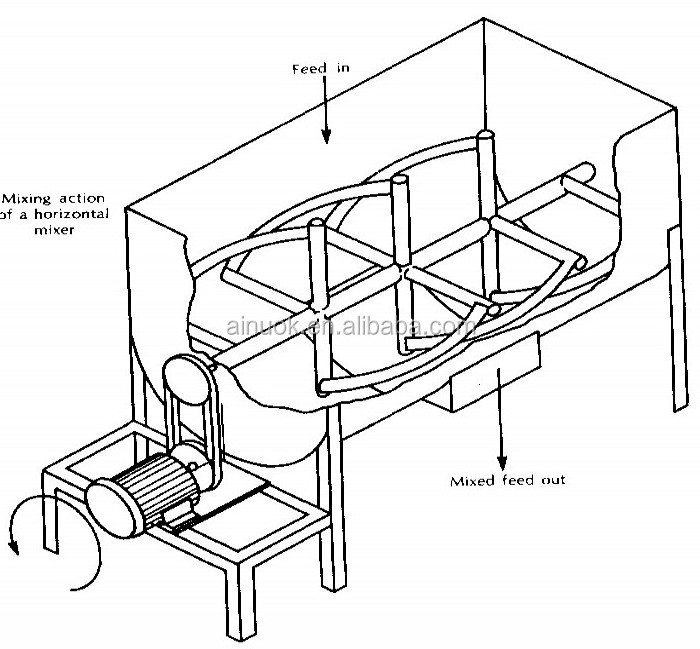

farm automatic mushroom spawn batch compost substrate material soil spiral mixer

In mushroom growing proces, we should process the grow compost and mix

all necessary material together.While mix process, maybe it will added some water. I n big mushroom plant, we need to use automatic mushroom substrate mixer . The horizontal mixer is mainly suitable for mixing feedstuffs in feed, chemical, dry mortar and animal husbandry industries. The new type is efficient, flexible and convenient. The mixing uniformity is high, and the labor cost is greatly saved. It is a good assistant for the majority of farmers. It is also suitable for planting (salting mushrooms, seed dressing, etc.), construction and other aspects, simple and convenient, and has a wide range of applications.

| Model | Power | Capacity | Volume | Packing dimension | Packing weight |

| AKH-101 | 5.5 kw (3phase) | 300 kg per time | 1.6 cubic | 240*115*136 cm | 750 kg |

| AKH-121 | 7.5 kw (3phase) | 500 kg per time | 2.8 cubic | 300*145*175 cm | 1000 kg |

Mushroom substrate mixer Advantages :

1. Greatly improving the quality of mixed material.

2. Makes cultivate medium with uniform humidity and nutrition distribution.

3. Increase the production yield.

4. Mixer Discharge automatically

5. Saving labor, improve working efficient.

6. Can matched with the bagging machine into production line.

7. Install wheels can moving to work in different places.