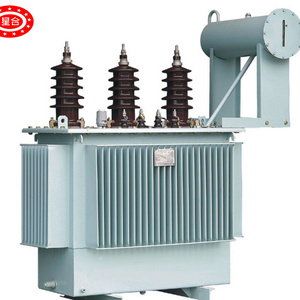

The S11 series is a three-phase oil immersed distribution transformer. The iron core material shall be cold-rolled silicon steel

sheets such as DQ133 (Type 9), 30ZH120 (Type 11), 23ZH90 (Type 13), etc. The iron core material used in actual production shall

not be lower than the requirements of the drawings.

The S11 and 10KV low loss power transformers adopt a fully sealed corrugated oil tank structure, and the transformer oil does not

come into contact with the surrounding air. Therefore, the transformer oil will not absorb external moisture, thereby not reducing

the insulation strength; In addition, due to the inability of oxygen to enter the fuel tank, the aging of insulation materials is

avoided, which improves the service life of the product and also improves social benefits.

Product model

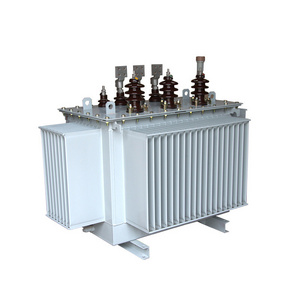

Good technical and economic performance: On the basis of the S9 series, the S11 product has an average reduction of 30% in no-load

losses and a decrease of 70-85% in no-load current compared to the S9 series.

Long service life: The transformer oil tank adopts a fully sealed structure, and the oil tank can be bolted or welded to the edge

of the tank. The transformer oil does not come into contact with air, extending its service life.

High operational reliability: The sealing components of the fuel tank have been improved to increase reliability and improve the

level of technology to ensure the reliability of the sealing.

Small footprint: The S11-M series power transformer oil tank adopts a corrugated plate radiator. When the oil temperature changes,

the corrugated plate can replace the role of the oil storage tank due to thermal expansion and contraction. The corrugated plate

oil tank has a beautiful appearance and a small footprint.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

S13-M, transformer

-

Coil Number:

-

3

-

Usage:

-

power disturbution

-

Coil Structure:

-

TOROIDAL

-

Frequency:

-

50HZ

-

Primary voltage:

-

10KV/11KV/24KV/33KV/36KV

-

Secondary voltage:

-

400V/415V

-

Core material:

-

Enamelled wire

-

Vector group:

-

Dyn11

-

Operating temperature:

-

35℃~95℃

-

Keyword:

-

oil transformer /power transformer

-

Rated Primary Voltage:

-

12000

-

Rated Secondary Voltage:

-

400

Quick Details

-

Phase:

-

Three

-

Place of Origin:

-

Zhejiang, China, zhejiang china

-

Brand Name:

-

KEEYA, HAYA

-

Model Number:

-

S13-M, transformer

-

Coil Number:

-

3

-

Usage:

-

power disturbution

-

Coil Structure:

-

TOROIDAL

-

Frequency:

-

50HZ

-

Primary voltage:

-

10KV/11KV/24KV/33KV/36KV

-

Secondary voltage:

-

400V/415V

-

Core material:

-

Enamelled wire

-

Vector group:

-

Dyn11

-

Operating temperature:

-

35℃~95℃

-

Keyword:

-

oil transformer /power transformer

-

Rated Primary Voltage:

-

12000

-

Rated Secondary Voltage:

-

400

Product Description

Specification

Product Introduction and Model

|

item

|

value

|

|

Place of Origin

|

Zhejiang China

|

|

|

|

|

Brand Name

|

KEEYA

|

|

Model Number

|

S13-M

|

|

Phase

|

Three

|

|

Coil Number

|

3

|

|

Usage

|

power disturbution

|

|

Coil Structure

|

TOROIDAL

|

|

Rated Primary Voltage

|

12000

|

|

Rated Secondary Voltage

|

400

|

|

Power

|

500KVA, 630KVA, 800KVA, 1000KVA, 1250KVA, Other

|

|

Place of Origin

|

zhejiang china

|

|

Brand Name

|

HAYA

|

|

Model Number

|

transformer

|

|

Frequency

|

50HZ

|

|

Primary voltage

|

10KV/11KV/24KV/33KV/36KV

|

|

Secondary voltage

|

400V/415V

|

|

Core material

|

Enamelled wire

|

|

Vector group

|

Dyn11

|

|

Operating temperature

|

35℃~95℃

|

|

Keyword

|

oil transformer /power transformer

|

Functional characteristics

1. The iron core is a seamless and non graded nearly pure circular cross-section made of silicon steel sheet material. The iron

yoke and iron core column are connected with rounded corners, and the iron core is in a closed shape. 2. The high and low voltage

coils are directly wound on the iron core, with good concentricity and short-circuit resistance. 3. Due to the special structure

of the iron core, which is made of high-quality cold-rolled silicon steel sheets with crystal orientation and annealed, the

S11-M.R transformer has a 30% reduction in no-load loss, a 70% reduction in no-load current, and a noise reduction of about 8

decibels compared to the same capacity S9 type. 4. Cancel the oil storage tank. Using a corrugated plate oil tank, the temperature

induced oil volume change is adjusted by the elasticity of the corrugated plate to isolate the transformer oil from the air and

prolong the service life. 5. The use of corrugated oil tanks for temperature rise occupies a small area and has a beautiful

appearance. 6. Fully mechanized iron core processing reduces labor intensity, improves product quality, and stabilizes quality.

yoke and iron core column are connected with rounded corners, and the iron core is in a closed shape. 2. The high and low voltage

coils are directly wound on the iron core, with good concentricity and short-circuit resistance. 3. Due to the special structure

of the iron core, which is made of high-quality cold-rolled silicon steel sheets with crystal orientation and annealed, the

S11-M.R transformer has a 30% reduction in no-load loss, a 70% reduction in no-load current, and a noise reduction of about 8

decibels compared to the same capacity S9 type. 4. Cancel the oil storage tank. Using a corrugated plate oil tank, the temperature

induced oil volume change is adjusted by the elasticity of the corrugated plate to isolate the transformer oil from the air and

prolong the service life. 5. The use of corrugated oil tanks for temperature rise occupies a small area and has a beautiful

appearance. 6. Fully mechanized iron core processing reduces labor intensity, improves product quality, and stabilizes quality.

|

Transformer service conditions

|

|

|

|

1

|

Maximum ambient temperature:+40 ℃

|

|

|

2

|

Minimum ambient temperature: -25 ℃

|

|

|

3

|

Altitude:

|

|

|

4

|

Maximum monthly average relative humidity: 90% (20 ℃)

|

|

|

|

Installation location: Installed indoors or outdoors in a location free from fire, explosion hazards, severe pollution, chemical

corrosion, and severe vibration. |

|

Product Features

1. The transformer core is made of imported high-quality cold-rolled silicon steel sheets stacked together, greatly reducing

no-load losses and currents. The core is also bound to ensure its compactness and reduce noise. 2. The high and low voltage

windings are wound with oxygen free copper. The low voltage winding of 500KVA and below adopts a double-layer cylindrical

structure, while the high voltage winding of 630KVA and above adopts a double helix or four helix structure. The high voltage

winding adopts a multi-layer cylindrical structure. 3. The transformer connection group adopts Dyn11 to reduce the impact of

harmonics on the power grid and improve power supply quality. 4. The transformer is a fully sealed structure, extending its

service life, free from hanging cores and maintenance. 5. The measured noise value is lower than the standard. After normal

transportation, this series of Satons transformers can be installed with relevant components and undergo acceptance project tests

without the need for hanging core inspection. Once qualified, they can be put into operation.

no-load losses and currents. The core is also bound to ensure its compactness and reduce noise. 2. The high and low voltage

windings are wound with oxygen free copper. The low voltage winding of 500KVA and below adopts a double-layer cylindrical

structure, while the high voltage winding of 630KVA and above adopts a double helix or four helix structure. The high voltage

winding adopts a multi-layer cylindrical structure. 3. The transformer connection group adopts Dyn11 to reduce the impact of

harmonics on the power grid and improve power supply quality. 4. The transformer is a fully sealed structure, extending its

service life, free from hanging cores and maintenance. 5. The measured noise value is lower than the standard. After normal

transportation, this series of Satons transformers can be installed with relevant components and undergo acceptance project tests

without the need for hanging core inspection. Once qualified, they can be put into operation.

Transformer Usage

Modern industrial enterprises widely use electricity as energy, and the electricity generated by power plants often needs to be

transmitted over long distances to reach the electricity consuming areas. When the transmission power is constant, the higher the

transmission voltage, the smaller the required current. Because the voltage drop is proportional to the current. The line loss is

proportional to the square of the current, so using a higher transmission voltage can achieve lower line voltage drop and line

loss. To manufacture a generator with a high voltage, it is currently difficult to use specialized equipment to raise the voltage

at the generator end and then transmit it out. This specialized equipment is a transformer. On the other hand, a step-down

transformer must be used at the receiving end to reduce the high voltage to the voltage of the distribution system, so a series of

distribution transformers must be used to reduce the high voltage to a suitable value for use.

transmitted over long distances to reach the electricity consuming areas. When the transmission power is constant, the higher the

transmission voltage, the smaller the required current. Because the voltage drop is proportional to the current. The line loss is

proportional to the square of the current, so using a higher transmission voltage can achieve lower line voltage drop and line

loss. To manufacture a generator with a high voltage, it is currently difficult to use specialized equipment to raise the voltage

at the generator end and then transmit it out. This specialized equipment is a transformer. On the other hand, a step-down

transformer must be used at the receiving end to reduce the high voltage to the voltage of the distribution system, so a series of

distribution transformers must be used to reduce the high voltage to a suitable value for use.

Transformer precautions

The transformer in operation must pay attention to the following points: 1. Prevent transformer overload operation. If overloaded

for a long time, it will cause the coil to heat up, gradually aging the insulation, causing inter box short circuit, phase short

circuit or ground short circuit, and oil decomposition. 2. Ensure the quality of insulation oil. During storage, transportation,

or operation and maintenance of transformer insulation oil, if the oil quality is poor or there are too many impurities or

moisture, it will reduce the insulation strength. When the insulation strength decreases to a certain value, the transformer will

short-circuit and cause electric sparks, arcs, or dangerous temperatures. Therefore, during operation, the transformer should

undergo regular oil quality testing, and unqualified oil should be replaced in a timely manner. Add Security Engineer Site to

Favorites 3. Prevent aging and damage to the insulation of the transformer core. Aging of the insulation of the iron core or

damage to the clamping bolt sleeve can cause significant eddy currents in the iron core, leading to long-term heating of the iron

core and insulation aging. 4. Prevent insulation damage due to careless maintenance. When repairing the hanging core of a

transformer, attention should be paid to protecting the coil or insulation sleeve. If any scratches or damages are found, they

should be dealt with in a timely manner. 5. Ensure good wire contact. Poor contact between the internal connectors of the coil, as

well as the connection points between the coils, the contacts leading to the high and low voltage side bushings, and the various

support points on the tap changer, can cause local overheating, damage insulation, and lead to short circuits or open circuits.

The high-temperature arc generated at this time will cause the insulation oil to decompose, producing a large amount of gas and

increasing the pressure inside the transformer. When the pressure exceeds the protection setting of the gas circuit breaker

without tripping, an explosion will occur. 6. Prevent electric shock. The power supply of power transformers is generally supplied

through overhead lines, which are prone to lightning strikes and can cause the transformer to burn down due to insulation

breakdown. 7. Short circuit protection should be reliable. If a short circuit occurs in the transformer coil or load, the

transformer will withstand a considerable short-circuit current. If the protection system fails or the protection setting is too

large, it may burn the transformer. For this reason, reliable short-circuit protection devices must be installed. 8. Maintain good

grounding. For low-voltage systems that use protective grounding, the neutral point on the low-voltage side of the transformer

should be directly grounded. When the three-phase load is unbalanced, current will appear on the neutral line. When the current is

too high and the contact resistance is high, a high temperature will occur at the grounding point, igniting the surrounding

combustible materials. 9. Prevent overheating. Temperature changes should be monitored during transformer operation. If the

transformer coil wire is A-grade insulation, the insulation is mainly made of paper and cotton yarn, and the temperature has a

significant impact on the insulation and service life. For every 8 ℃ increase in temperature, the insulation life will be reduced

by about 50%. The transformer operates at normal temperature (90 ℃) and has a lifespan of approximately 20 years; If the

temperature rises to 105 ℃, the lifespan is 7 years. If the temperature rises to 120 ℃, the lifespan is only two years. So when

the transformer is running, it is necessary to maintain good ventilation and cooling. If necessary, forced ventilation can be

adopted to reduce the temperature rise of the transformer

for a long time, it will cause the coil to heat up, gradually aging the insulation, causing inter box short circuit, phase short

circuit or ground short circuit, and oil decomposition. 2. Ensure the quality of insulation oil. During storage, transportation,

or operation and maintenance of transformer insulation oil, if the oil quality is poor or there are too many impurities or

moisture, it will reduce the insulation strength. When the insulation strength decreases to a certain value, the transformer will

short-circuit and cause electric sparks, arcs, or dangerous temperatures. Therefore, during operation, the transformer should

undergo regular oil quality testing, and unqualified oil should be replaced in a timely manner. Add Security Engineer Site to

Favorites 3. Prevent aging and damage to the insulation of the transformer core. Aging of the insulation of the iron core or

damage to the clamping bolt sleeve can cause significant eddy currents in the iron core, leading to long-term heating of the iron

core and insulation aging. 4. Prevent insulation damage due to careless maintenance. When repairing the hanging core of a

transformer, attention should be paid to protecting the coil or insulation sleeve. If any scratches or damages are found, they

should be dealt with in a timely manner. 5. Ensure good wire contact. Poor contact between the internal connectors of the coil, as

well as the connection points between the coils, the contacts leading to the high and low voltage side bushings, and the various

support points on the tap changer, can cause local overheating, damage insulation, and lead to short circuits or open circuits.

The high-temperature arc generated at this time will cause the insulation oil to decompose, producing a large amount of gas and

increasing the pressure inside the transformer. When the pressure exceeds the protection setting of the gas circuit breaker

without tripping, an explosion will occur. 6. Prevent electric shock. The power supply of power transformers is generally supplied

through overhead lines, which are prone to lightning strikes and can cause the transformer to burn down due to insulation

breakdown. 7. Short circuit protection should be reliable. If a short circuit occurs in the transformer coil or load, the

transformer will withstand a considerable short-circuit current. If the protection system fails or the protection setting is too

large, it may burn the transformer. For this reason, reliable short-circuit protection devices must be installed. 8. Maintain good

grounding. For low-voltage systems that use protective grounding, the neutral point on the low-voltage side of the transformer

should be directly grounded. When the three-phase load is unbalanced, current will appear on the neutral line. When the current is

too high and the contact resistance is high, a high temperature will occur at the grounding point, igniting the surrounding

combustible materials. 9. Prevent overheating. Temperature changes should be monitored during transformer operation. If the

transformer coil wire is A-grade insulation, the insulation is mainly made of paper and cotton yarn, and the temperature has a

significant impact on the insulation and service life. For every 8 ℃ increase in temperature, the insulation life will be reduced

by about 50%. The transformer operates at normal temperature (90 ℃) and has a lifespan of approximately 20 years; If the

temperature rises to 105 ℃, the lifespan is 7 years. If the temperature rises to 120 ℃, the lifespan is only two years. So when

the transformer is running, it is necessary to maintain good ventilation and cooling. If necessary, forced ventilation can be

adopted to reduce the temperature rise of the transformer

Hot Searches