Max 300mm height depending on the products.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MILES

-

Weight:

-

40 KG, 40kg

-

Dimension(L*W*H):

-

550*500*600mm

-

Model:

-

MT-C150

-

Max size of product:

-

150*150mm

-

Min size of product:

-

50*50mm

-

Thickness of products:

-

0.06mm-6mm

-

Stacking height:

-

300mm

-

Counting speed:

-

80-200pcs/min

-

Dimension:

-

550*500*600mm

Quick Details

-

Voltage:

-

380V/50HZ CUSTOMIZED, 220V/110V,AC

-

Power:

-

0.4KW, 0.4KW

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MILES

-

Weight:

-

40 KG, 40kg

-

Dimension(L*W*H):

-

550*500*600mm

-

Model:

-

MT-C150

-

Max size of product:

-

150*150mm

-

Min size of product:

-

50*50mm

-

Thickness of products:

-

0.06mm-6mm

-

Stacking height:

-

300mm

-

Counting speed:

-

80-200pcs/min

-

Dimension:

-

550*500*600mm

Video Description

Product Description

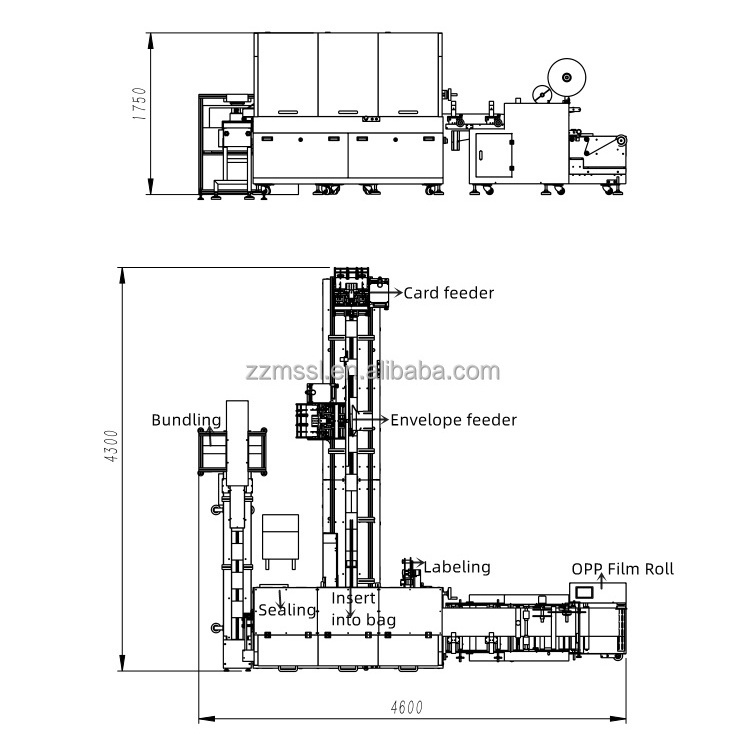

Card Pillow Packing Machine Card Plastic Paper Packing Machine Flow Wrapping Machine For Sorted Cards Collection

Application:

This machine is mainly used for automatic point feeding and packaging of various toy cards, manuals, stationery paper cards and other products.

Technical Features:

1. The three-servo PLC/DP control is stable and reliable, the bag length can be set and used immediately, and the automatic tracking accuracy is extremely high.

2. The touch screen or LCD text liquid crystal display is intuitive, and the man-machine interaction interface is simple and convenient to operate.

3. The mechanical structure is simple, stable and reliable, easy to maintain, and can realize stepless speed regulation or constant speed setting.

4. The special V-shaped bag maker has stable forming, smooth entrance, no film running, and beautiful sealing effect.

5. The sealing and heating integrated back-sealing structure can be selected. The packaging is compact, and the design of the feeding structure is flexible.

Specification

|

Model

|

MT-C150

|

MT-C300

|

MT-C420

|

||

|

Max size of product

|

150*150mm

|

300*300mm

|

420*420mm

|

||

|

Min size of product

|

50*50mm

|

60*60mm

|

100*100mm

|

||

|

Thickness of products

|

0.06mm-6mm

|

0.06mm-6mm

|

0.06mm-6mm

|

||

|

Stacking height

|

300mm

|

300mm

|

300mm

|

||

|

Counting speed

|

80-200pcs/min

|

80-200pcs/min

|

80-200pcs/min

|

||

|

Power

|

0.4KW

|

0.4KW

|

0.4KW

|

||

|

Voltage

|

220V/110V, AC

|

220V/110V, AC

|

220V/110V, AC

|

||

|

Weight

|

40kg

|

50kg

|

60kg

|

||

|

Dimension

|

550*500*600mm

|

650*580*600mm

|

750*650*600mm

|

||

|

Optional

|

Collecting hopper, Auto hopper, Conveyor, etc

|

|

|

||

Details Images

Automatic Feeding Table

Feeding hopper. The product is at an oblique angle to the belt.

Automatic Friction Feeder

150/300/420 model feeder is optional.

Reasonable structure design, suitable for products of different sizes and thicknesses.

Touch Screen English/Korean

Servo motor drive system, PLC controller and touch screen, easy to operate. Chain push rod type conveying, is the product is ready to be conveyed and stacked neatly

Width and Height is adjustable.

Different card feeding machines can be selected according to different sizes of cards.

Output Conveyor

Chain push rod type conveying, is the product is ready to be conveyed and stacked neatly. Meet different quantity requirements.

Pillow Packing Type/Back Sealed Bag Type

Independent temperature control for each sealer makes the perfect and tight sealing and suitable for a wide variety of flexible packing materials.

Packing parts

Three servo motor driver, digital screen display and PLC control, running stable and overload protection.It is not necessary to adjust manually after setting.

Friction Feeders

The quantity of feeder is according to your requirements.

Real-time photoelectric monitoring, accurate counting, with automatic storage function.

Real-time photoelectric monitoring, accurate counting, with automatic storage function.

Optional device:

hot-melt date coding machine

◆Automatic supply device

◆Stencil printing device

◆Hanging hole exhaust device

◆Inflatable device

Recommend Products

Packing & Delivery

Hot Searches