- Superior precision and stability are guaranteed by the casting beam and base frame of Y-axis.

- Lathe bed and water tank are non-detachable, After the annealing treatment of whole machine table (to eliminate the stress of 95%), it is much better than the VSR (to eliminate the stress is 35%). It can ensure the accuracy and stability in long time.

- X-axis and Y-axis adopt high-precision ball screw and guide linear rail.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Rongwin

-

Voltage:

-

380V 220V Optional

-

Rated Power:

-

30kw/40hp or 37kw/50hp

-

Dimension(L*W*H):

-

3880*2150*2000mm

-

Year:

-

2020

-

Weight (KG):

-

10000 KG

-

Name:

-

CNC Water Jet Cutting Machine

-

Brand:

-

Rongwin

-

Keyword:

-

waterjet

-

Pump type:

-

High Pressure Pump

-

Control system:

-

CNC Controller

-

Application:

-

Industrial Metal Cutting

-

Cutting material:

-

Stone Metal Glass.etc

-

Color:

-

Optional

-

Cutting mode:

-

Waterjet cutting

-

Ball screw:

-

HIWIN

Quick Details

-

Place of Origin:

-

Anhui, China

-

Table Travel (X) (mm):

-

1500

-

Table Travel (Y) (mm):

-

3000

-

Brand Name:

-

Rongwin

-

Voltage:

-

380V 220V Optional

-

Rated Power:

-

30kw/40hp or 37kw/50hp

-

Dimension(L*W*H):

-

3880*2150*2000mm

-

Year:

-

2020

-

Weight (KG):

-

10000 KG

-

Name:

-

CNC Water Jet Cutting Machine

-

Brand:

-

Rongwin

-

Keyword:

-

waterjet

-

Pump type:

-

High Pressure Pump

-

Control system:

-

CNC Controller

-

Application:

-

Industrial Metal Cutting

-

Cutting material:

-

Stone Metal Glass.etc

-

Color:

-

Optional

-

Cutting mode:

-

Waterjet cutting

-

Ball screw:

-

HIWIN

Product Description

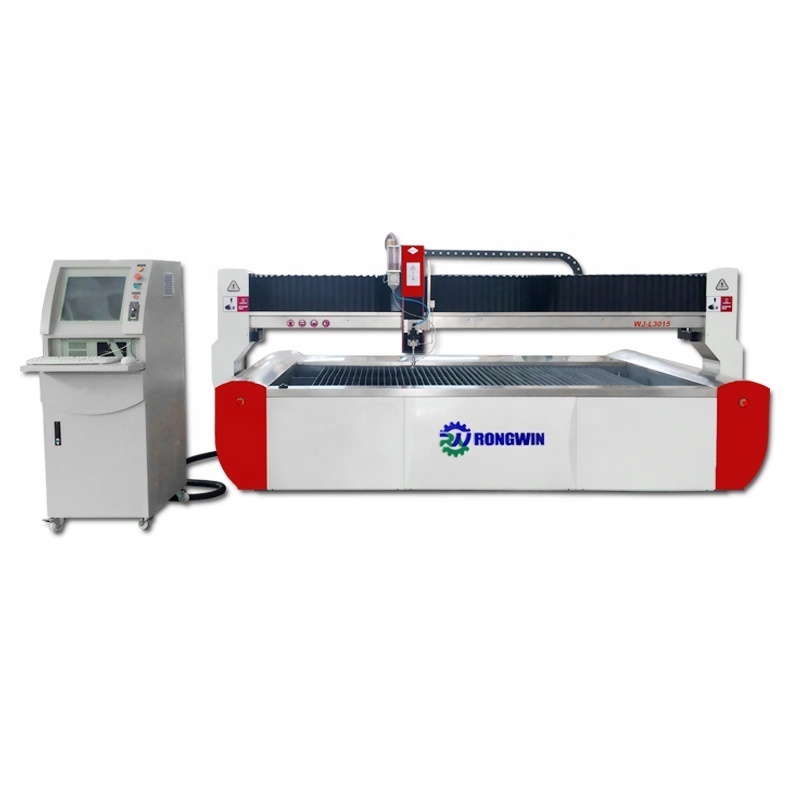

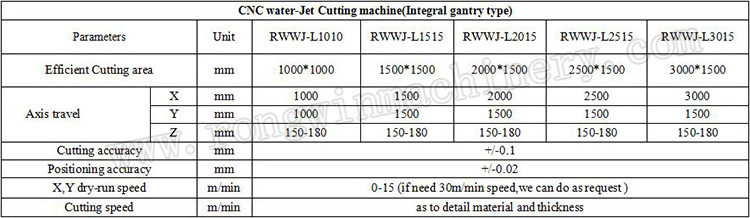

Cnc Portable Flow Ston Marble Mosaic And Granite Water Jet Cutter Waterjet Cutting Machine Price

Rongwin Waterjet Cutting Machine Water Jet Cutter equipment operates with the world’s most unique cold-cutting technology, making it suitable for cutting any type of materials in a diverse range of industries. It is widely applied in the industry like steel, nonferrous metal, glass, stone and cemented carbide. In addition, our product is widely seen in the processing of plastic, man-made fiber cloth, paper, composite, food aviation and car interior decoration processing. Etc.

Featuring a low noise, no pollution, high precision and high reliability.

CNC water jet cutting machine consists of three basic parts: high pressure system, cutting platform and control system.

Other optional, such as: automatic sand supply system, cooling system.

Contact us to give you the best advice.

- Superior precision and stability are guaranteed by the casting beam and base frame of Y-axis.

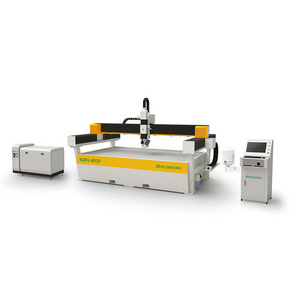

- Lathe bed and water tank are detachable, which are designed to reduce the pressure from water with sands and machined parts to moving parts.

- The base of Y-axis is overall manufacturing, It’s convenient for disassembly, transportation and assembly.

- X-axis and Y-axis adopt high-precision ball screw and guide linear rail.

- Lathe bed and water tank are detachable, which are designed to reduce the pressure from water with sands and machined parts to moving parts.

- The base of Y-axis is overall manufacturing, It’s convenient for disassembly, transportation and assembly.

- X-axis and Y-axis adopt high-precision ball screw and guide linear rail.

-the size of cutting table can be customized, the max size can be 4000mm*12000mm.

- Lathe bed and water tank are detachable, which are designed to reduce the pressure from water with sands and machined parts to moving parts.

- The base of Y-axis is overall manufacturing, It’s convenient for disassembly, transportation and assembly.

-For the small integral table, Lathe bed and water tank are non-detachable, After the annealing treatment of whole machine table (to eliminate the stress of 95%), it is much better than the VSR (to eliminate the stress is 35%),It can ensure the accuracy and stability in long time.

Main Feature

Control: PLC

Shifting: electro-hydraulic

Control Cooling: cooler/oil heat exchanger

Inlet water filter accuracy: ≤0.45μm

Oil-return filter accuracy: 20 μm

Working temp: 0-50°c

Outlet: UNF 3/8" Cooling in/out-let: NPT1"

Max orifice size: 0.33mm

40HP/50HP/100HP

Cutting Head

1, Standard waterjet cutting head

A high pressure water jet cutting machine is a tool used for slicing metal and other materials using a jet of water at high velocity and pressure. Featuring a low noise, no pollution, high precision and high reliability, our water jet cutting machine has been used in a variety of applications, including mining, automobile manufacturing, paper manufacturing, food, art and architecture. Water jet machines can be used to cut rubber, foam, plastic, composite, stone, tile, marble, glass and other materials.

2, Dynamic 5 cutting head

Rongwin

Dynamic 5 axis water jet cutting machine is specially used to cut marble and granite, it can compensate 10° cutting angle. It is a kind of bevel cutting machines.

Due to the water jet cutting is a way of flexible cutting, therefore the product cross section after cutting by the traditional 3 axis water jet cutting machine will have a certain degree of inclination. In order to ensure the accuracy of vertical cutting section, it must reduce the cutting speed. However, our 5 axis water jet cutting machine can ensure the accuracy of vertical cutting section by compensating the cutting angle, without reducing the cutting speed. So that it can be used for cutting parquet stone, the parquet flooring does not need to be polished again, which can save time and labor.

3, Max 5 cutting head

This Max 5 waterjet cutter can cut any angle within ±45°, it solves the traditional problem of water cutting inclination, and achieves 2D/3D cutting easily.

4, Cutting head with drilling function

It perfect combination of automatic drilling assembly and CNC waterjet system can achieve the automatic drilling, automatic feeding, automatic chip removal, pre-drilling before cutting and other functions for smaller pore. It has the ability to complete a one-time cutting drilling, that improve the quality of products, but also improve the efficiency of production.

5, Multi-head

Double cutting head or multiple cutting head means have two or more cutting heads on a cutting platform, that at the same time can perform the cutting task with the same track.

Mainly for large quantities of small parts,the capacity can be double or more under equivalent energy consumption.

High pressure water jet is mainly divided into two types:

Abrasive cutting

is mainly for metals (such as carbon steel, stainless steel, etc.), non-ferrous metals (such as copper, aluminum, titanium alloy, magnesium alloy, etc.), stone, glass, large thickness composite materials (such as carbon fiber, glass fiber), etc.

Pure water cutting

is mainly for rubber, foam, cloth, paper, rock wool, food, etc.

|

Item

|

Value

|

|

Brand Name

|

Rongwin

|

|

Voltage

|

380V 220V Optional

|

|

Certification

|

CE ISO

|

|

Key Selling Points

|

High-accuracy

|

|

Name

|

CNC Water Jet Cutting Machine

|

|

Brand

|

Rongwin

|

|

Keyword

|

water jet cutter

|

|

Pump type

|

High Pressure Pump

|

|

Control system

|

CNC Controller

|

|

Ball screw

|

HIWIN

|

Remote Control System

The hand-held controller is available with a choice of wired or wireless handwheel. It is designed to control a machine tool remotely. This control console provides a convenient and intuitive solution for tool setting. It overcomes the problem when using a conventional tool setting method and also provides much convenience for observation and operation.

Description:

1. Overturn angle: 70°(measured up from the horizon)

2. Max. overturning moment load capacity: 350KG

3. The large cutting platform is hydraulically operated to overturn, which enables this hydraulic loader to load or unload an entire piece of stone while ensuring a minimum material loss and a high level of efficiency when the stone loading unit is running.

Features:

(1) Air pressure is used to convey power to the abrasive. (Translate these five articles)

(2) Air pressure 0.2MPA

(3) Flow rate<0.3M³/min

(4) The volume of the sand storage bucket can store 200KG at a time

(5) Maximum sand feeding amount 0-1000K/MIN

(6)

Automatic & High accuracy greatly reduce the workload of the workers.

Remove the abrasive from the tank automatically,separate the abrasive and water.Reduce the labor force,improve work efficiency.The absorption pump sucks up the mixture of sand and water from the tank into a collection box when it works.There are plastic woven filter bags in the collection box,water is recycled to the machine tank, sand and the mixturefrom cutting are collected into filter bags Inside. So as to achieve the purpose of automatic collection to make it easy to clean.

Description:

Many kinds of compounds exist in the running water (such as calcium carbonate, carbonic acid). As the machine works, the temperature rise will generate some substance of the reaction of chemistry or physics-as we called it furring, which will reduce the life of the high pressure system and increase the cost. After many years' experience, we have developed the system that can solve the problem. We would like to recommend you this optional part if your supplied water is low quality.

Air cooling system:

Increased cooling area and increased ventilation flow is hardly affected by the working environment, and is equipped with an independent automatic temperature control system, independent cooling circuit, when the temperature reaches the set value, the air cooler is jobs. Clean, energy saving and environmental protection.

Water Cooling Tower:

guarantee the hydraulic system can be used in a circular manner and save water.

Water Chiller:

can take the place of water cooling tower, and much more efficient, if the temperature is high, this one is your best choice.

Packing & Shipping

Hot Searches