- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

5000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Eceng

-

Voltage:

-

Customer

-

Dimension(L*W*H):

-

7.8x1.95x1.9m

-

Hollow part volume:

-

5L

-

Weight (KG):

-

10600 KG

-

Blow Moulding Type:

-

Stretch Blow Moulding

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Product name:

-

Automatic Blowing Molding Machine

-

Suitable bottle:

-

Drink Bottle

-

Bottle material:

-

PET Material

Quick Details

-

Neck Diameter(mm):

-

63 mm

-

Max.Bottle Diameter(mm):

-

185 mm

-

Max.Bottle Height(mm):

-

360 mm

-

Bottle Volume(ml):

-

5000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Eceng

-

Voltage:

-

Customer

-

Dimension(L*W*H):

-

7.8x1.95x1.9m

-

Hollow part volume:

-

5L

-

Weight (KG):

-

10600 KG

-

Blow Moulding Type:

-

Stretch Blow Moulding

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Product name:

-

Automatic Blowing Molding Machine

-

Suitable bottle:

-

Drink Bottle

-

Bottle material:

-

PET Material

T echnical P arameters

|

Model K 5L4 |

||

|

Bottle type specification

|

Cavity |

4 |

|

Max.volume |

3L-5 L |

|

|

Bottle mouth maximum overall diameter |

38-63 mm |

|

|

Bottle biggest diameter |

1 85 mm |

|

|

Bottle maximum height |

3 6 0mm |

|

|

Capacity specification

|

Theory output |

3500-4000 BPH |

|

Bottle type volume |

50 00ML |

|

|

Bottle type weight |

60 g |

|

|

Bottle type |

Round |

|

|

Power specification |

Light tube quantity |

32 pcs |

|

Light tube power |

2 KW |

|

|

Maximum heating power |

64 KW |

|

|

All electric machine installation |

75 KW |

|

|

Actual consumption |

30%--60% |

|

|

Air pressure specification

|

Work pressure |

5-6 kg/cm2 |

|

Blow bottle pressure |

25- 4 5kg/cm2 |

|

|

Higher -pressure gas consumption |

8 000 Ltr/min |

|

|

Forzen water specification |

Work pressure |

5-6 kg/cm2 |

|

Temperature range |

10℃ |

|

|

Consumption |

1 8 000 kcal/hr |

|

|

Forzen water flow |

1 2 0 L/min |

|

|

Machine specification |

Machine size |

7.8*1.95*1.9 |

|

Machine weight |

10.6 ton |

|

Product Features:

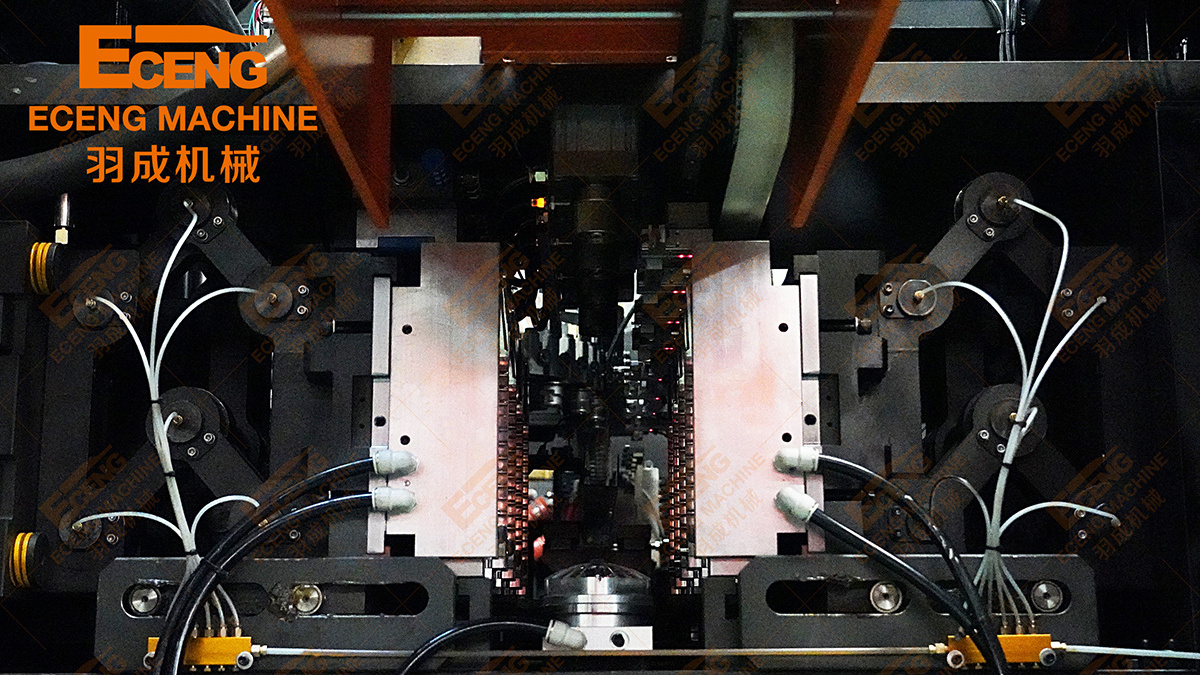

K series linear bottle blowing machine is used in the production of PET water bottles,hot filling bottles,carbonated beverage bottles and edible oil bottles. Eceng Machinery K series linear bottle blowing machine stretches the preform by controlling the stretching rod by servo motor. The advantage is that it can be stretched in sections, firstly position the preform,ensur e the verticality of the preform when stretching then secondary stretching.Ensure uniformity and consistency of stretch of each preform . At the same time, the blower is faster and less energy consumed .

K Series Linear Bottle Blowing Machine Features:

1.K s eries linear bottle blowing machine , high speed and stable running and precise positioning.It adopts advanced microcomputer PLC control system and can be more stable.

2.The production process is fully automated,with the advantages of low investment,high efficiency,convenient operation,simple maintenance and safety.

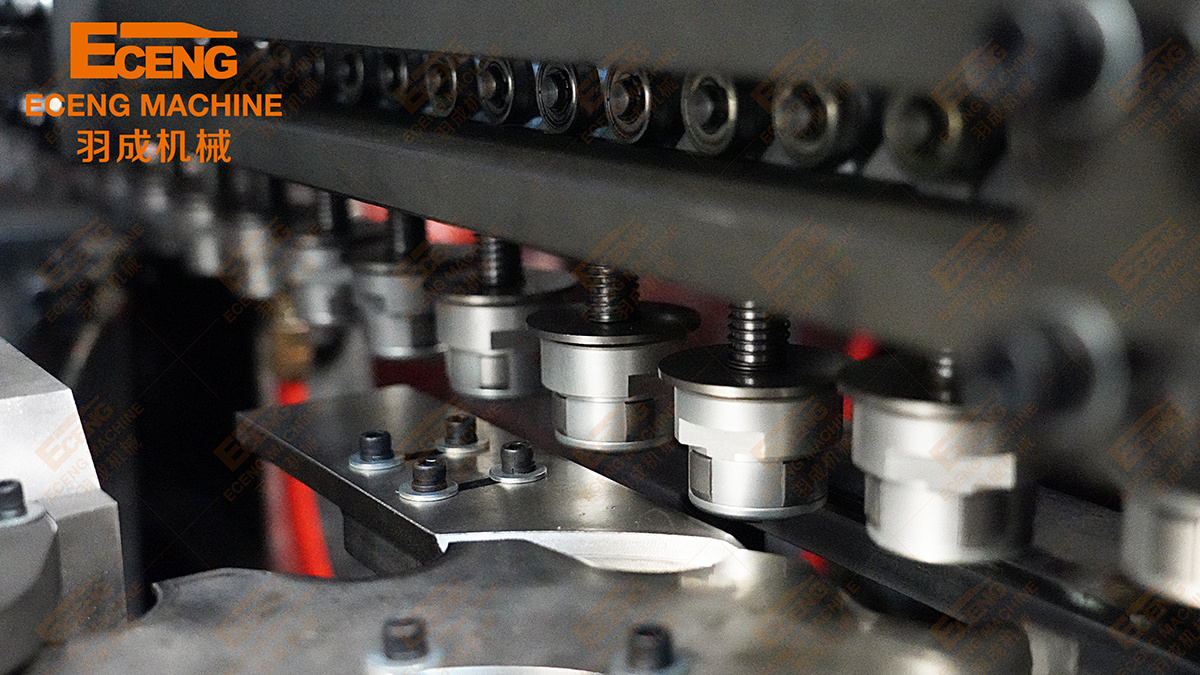

3.Servo transmission system, high positioning accuracy, fast speed and good reliability.

4.Suitable for small quantity flexible production,wide range of applications, suitable for customer needs.

5. Energy efficiency is improved, energy is saved, and capacity per unit time is increased.

6. O peration mode is manual or fully automatic, easy to control and operate the HMI .

7. Servo transmission system, high positioning accuracy, fast speed and good reliability.

8. Each mechanical action has a safety self-locking device. When a certain process fails,program will automatically switch to the safe state.

9.Compared with the Q series, the heat and noise are obvious ly reduced.

10.K series linear bottle blowing machinee bottle rejection rate is less than 0.2%.

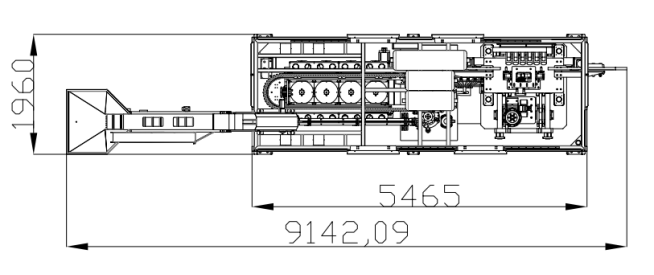

Layout :

Auxiliary E quipment:

|

|

1, High pressure air compressor Air compressor system,combined series of high pressure air system for use,convenient maintenance,easy inspection and troubleshooting |

|

|

2 , C hiller mainly used to cool the mold,ensure bottle body will not be damaged while heating process,improve the quality of finished bottles and production efficiency |

|

|

3, Filter system

Mainly function is cooling high pressure air to a better working temperature,extend using life of pneumatic component,filter impurity and oil in the air,improve product cleanliness. |

I nstallation and C ommissioning

Equipment engineer will be arranged to install and debug in buyer’s factory with free of charge, According to the requirement of the technical department of the demander to draw the plan layout and installation construction drawings, basic drawings, equipment contour size and inter-spacing, etc., to draw lines and locate, organize the basic construction and equipment in place.

After S ales S ervice

1. One year warranty,during warranty period,All parts and components except those damaged by non-human factors are guaranteed free of charge (vulnerable parts are not included). In addition, the seller provides free spare parts and accessories for shipment with the machine.

2 . During warranty period ,the equipment is damaged due to incorrect operation by

t he buyer,we provide maintenance solutions,the buyer will cover the loss and cost.during warranty period we provide technical service,which is usually solved by telephone,etc.if not,provide door-to-door service.

Component D isplay:

|

|

|

|

|

|

|

|

|