- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

L4200XW2800XH2800MM

-

Weight:

-

13000

-

Power (kW):

-

11

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Geekung

-

Voltage:

-

220V/380V/440V/480V

-

Dimension(L*W*H):

-

L4200XW2800XH2800MM

-

Weight:

-

13000

-

Power (kW):

-

11

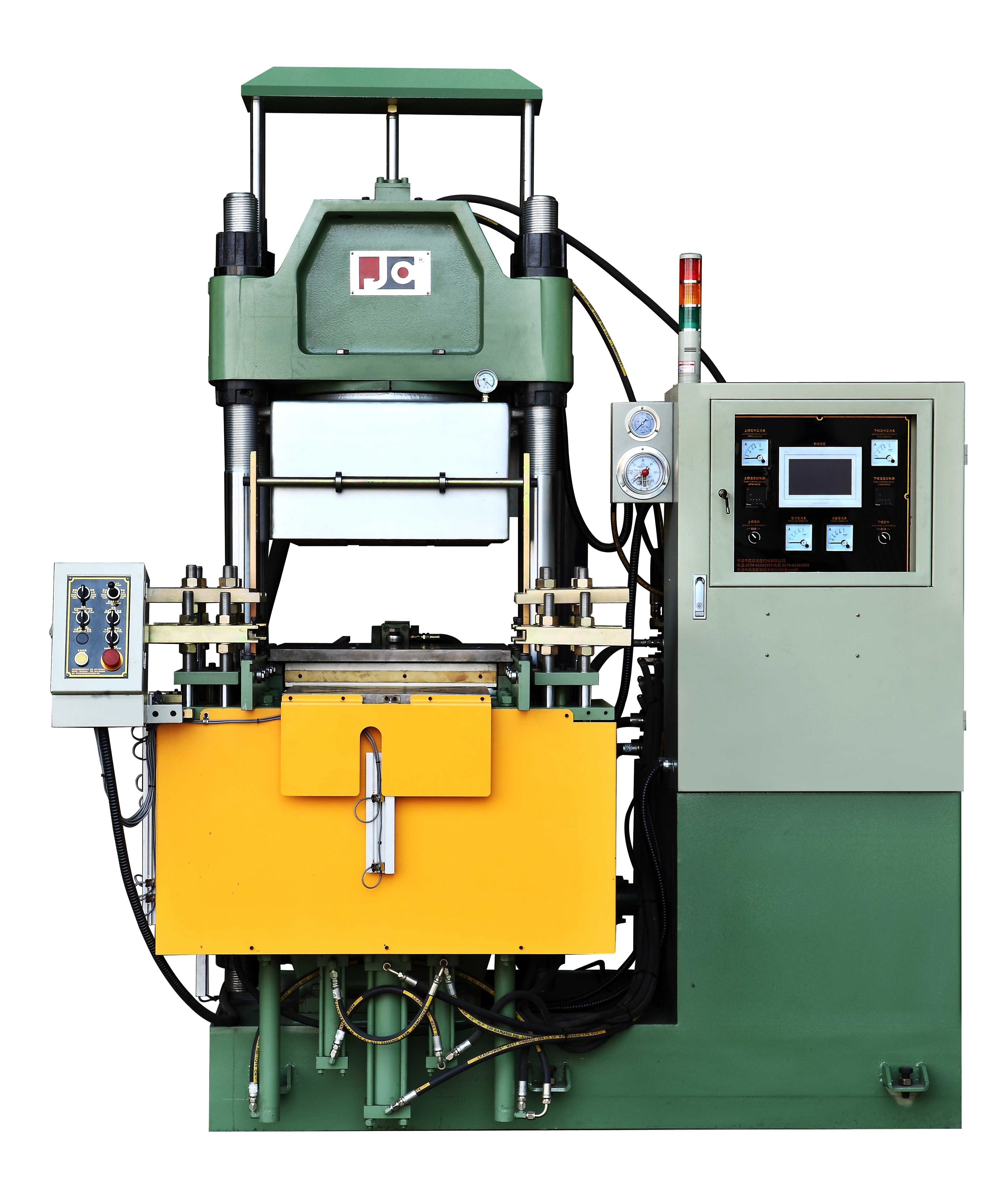

Vulcanizing Machine with Vacuum System is one of our main products,"Geekung" is the famous brand in China for Vacuum Compression Molding Press Machine,made with premium components and strict QC management,featuring high quality&reliable operation,durable service life,our Vacuum Compression Molding Press Machine are being sold very popular across China,enjoying good reputation,we are now also expanding our overseas market.

A pplications : The Vacuum Compression Molding Press Machineis i deal for the production of making rubber or silicone parts, such as rubber oil seal,O-rings, keyboards, connector,bushing, rubber medical products,etc.

Features for our Vulcanizing Machine with Vacuum System :

1. The world-class brand vacuum pump &vacuum housing provide highly efficient vacuum suction effect for the entire mold inside the heating platen, making the rubber materials more dense and free of air,ensuring perfect final finished rubber products.

2. OurVacuum Compression Molding Press Machine is installed with integrated hydraulic circuit providing various pip ing functions on the circuit boards, reducing piping to a minimum. The oil cooler ensures long service life of the circuit valve s .

3. Hydraulic pressure & speed contro l system adopt optimized and advanced p roportional pressure valve and proportional fl ux valve with loop circuit feedback control from PLC ,realizing reliable and smooth “high speed-low speed ”clamping operation.

4. The main components of the Vacuum Compression Moulding Press Machine for Oil Seal machine such as the top base,middle base and cylinder body are all made of premium ductile cast iron,ensuring the durable high stability of the machine even after many years service,won’t have the problem of deformation.

5. P arallelism of hot plate s is controlled with the tolerance of 0.0 3 mm per 300mm .

6. The temperature tolerance of each point on the upper and lower plates is within ±2℃ .PID temperature calibration .

7. P reheating function is available to set on the HMI (touch screen).

8. R eplacement time of lubricating oil can be set up from touch screen and auto alarm .

9. Time- c ounting for machine working time. S afety interlock for movement, fool-proof design . Automatic a bnormal a larm function.

10. PLC monitor entire production ,1000 production recipes can be save d and USB data transmission conveniently .Remote Touch s creen password setting.

11. Remote control provides more convenient after sales service ,even the customers are far away in another country, our engineer can reach your control system to conduct necessary maintenance or update Geekung Vacuum Vulcanizing Press Machine with the newest system.

12. Pressure p rotection d esign ensure the safe working of the machine.

13. Safety l ight c urtain device to prevent operators from potential injury.

14. A utomatic retrieval of machine faults, automatic display of machine action positioning .

15. All control components for our Vacuum Compression Moulding Press Machine for Oil Seal adopts world-class famous brand, like Omron PLC,Fuji display,Yuekn valves,Busch vacuum pump,TECO motor,Schneider electric elements,etc.

16. Various high efficient rubber product demoulding devices are availab le for options, such as sliding plate, side ejector, reverse plate, low clapper,etc,depends on your product strucutre, you can choose 2RT , 3RT or 4RT system to remove the final products automatically from the mold.

17. Single station or double stations are available for option.

18. CE Certificate is available.

|

Clamping Force

|

Main Ram

|

Heating Platen

|

Stroke of

|

Daylight

|

Power

|

Power

|

|

100 |

Ø250 |

405x430 |

250 |

300 |

14.0 |

24.3 |

|

150 |

Ø300 |

450x480 |

250 |

300 |

16.4 |

32.8 |

|

200 |

Ø355 |

505x510 |

250 |

300 |

23.1 |

42.4 |

|

250 |

Ø400 |

570x610 |

250 |

300 |

25.8 |

47.8 |

|

350 |

Ø457.2 |

700x700 |

250 |

300 |

25.8 |

47.8 |

|

500 |

Ø560 |

700x700 |

250 |

300 |

29.5 |

59.0 |

|

850x850 |

40.0 |

80.0 |

||||

|

1000x1000 |

49.6 |

99.2 |

Notes: the form only list out the normal standard model, more special models can be customized to order.