- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KNOWN

-

Voltage:

-

Three phase voltage / Diesel type

-

Dimension(L*W*H):

-

160*145*180 cm

-

Motor Power (Kw):

-

15kw

-

Power (kW):

-

15kw

-

Weight (KG):

-

380 KG

-

Item:

-

Crusher combined with pelletizer

-

Pellet machine type:

-

Roller rotating type

-

Application:

-

produce feed / fuel pellets

-

Engine type:

-

Electric / Diesel

-

Sawdust moisture:

-

10~18%

-

Spare parts:

-

flat die and roller

-

Usage:

-

Wood Feed Pellet Making Machine

-

Keywords:

-

Woode Feed Pellet Machine

-

Type:

-

Flat Die Biomass Pellet Mill

-

Main product:

-

wood crusher machine for sale

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

100 - 150 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KNOWN

-

Voltage:

-

Three phase voltage / Diesel type

-

Dimension(L*W*H):

-

160*145*180 cm

-

Motor Power (Kw):

-

15kw

-

Power (kW):

-

15kw

-

Weight (KG):

-

380 KG

-

Item:

-

Crusher combined with pelletizer

-

Pellet machine type:

-

Roller rotating type

-

Application:

-

produce feed / fuel pellets

-

Engine type:

-

Electric / Diesel

-

Sawdust moisture:

-

10~18%

-

Spare parts:

-

flat die and roller

-

Usage:

-

Wood Feed Pellet Making Machine

-

Keywords:

-

Woode Feed Pellet Machine

-

Type:

-

Flat Die Biomass Pellet Mill

-

Main product:

-

wood crusher machine for sale

Product Description

Crusher Combined With Pelletizer Hammer Mill Combined Wood Pellet Making All In One Machine For Sale

Brief introduction of crusher combined with pelletizer

This type machine is hammer mill and pellet mill two in one machine, it can save labor and energy consumption. It mainly from straw, corn stalk, rice stalk etc to produce into 6MM/8MM/10MM/12MM Pellet for biomass fuel / Animal feed.

The hammer mill is used to crushing material into powder shape before enter into pellet mill, and then the powder shape material directly enter into pellet mill to pressing pellets. This type machine can be use diesel engine or electrical motor driven, the hammer mill and pellet mill used the same diesel engine or electrical motor.

The hammer mill is used to crushing material into powder shape before enter into pellet mill, and then the powder shape material directly enter into pellet mill to pressing pellets. This type machine can be use diesel engine or electrical motor driven, the hammer mill and pellet mill used the same diesel engine or electrical motor.

The specification of crusher combined with pelletizer

|

-- Electric type:

|

|

|

|

|

|

|||||

|

MODEL NO.

|

OUTPUT(KG/H)

|

POWER (KW)

|

PELLET DIAMETER(mm)

|

SIZE(cm)

|

WEIGHT(KG

|

|||||

|

KN-YD-200

|

100-150

|

15

|

6-8

|

160*145*180

|

450

|

|||||

|

KN-YD-250

|

200-300

|

22

|

6-10

|

175*160*190

|

580

|

|||||

|

KN-YD-300

|

300-400

|

30

|

6-12

|

180*165*190

|

700

|

|||||

|

-- Diesel type:

|

|

|

|

|

|

|||||

|

MODEL NO.

|

OUTPUT(KG/H)

|

POWER (HP)

|

PELLET DIAMETER(mm)

|

SIZE(cm)

|

WEIGHT(KG

|

|||||

|

KN-YD-200A

|

100-150

|

22

|

6-8

|

160*145*180

|

600

|

|||||

|

KN-YD-250A

|

200-300

|

32

|

6-10

|

175*160*190

|

700

|

|||||

|

KN-YD-300A

|

300-400

|

35

|

6-12

|

180*165*190

|

820

|

|||||

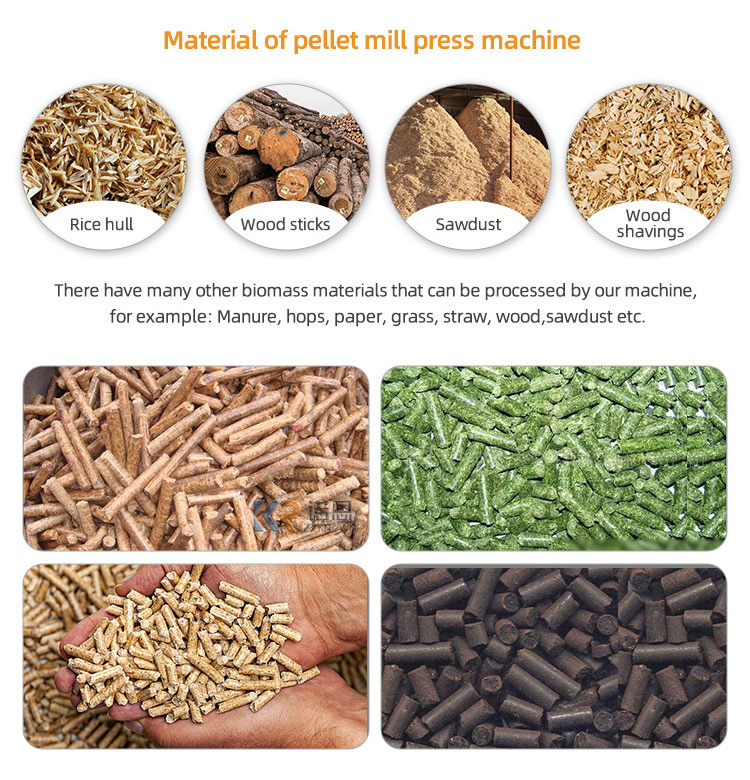

The raw material of crusher combined with pelletizer

It has wide range of materials, such as sawdust, wood, straw, rice husk, bagasse, cotton stalk, peanut shell, bamboo, empty fruit branch, pulverized coal, waste paper, cottonseed skins, weeds, crop stalks and other plant wastes, especially low-bonding and unformed materials and other can be making into biomass pellets without any additive.

|

For the pellets production, here is the requirements for the raw materials:

|

|

|

|

1.

|

Sawdust Size: 2~5mm

|

|

|

2.

|

Sawdust Moisture: 10-18%

|

|

|

We also supply the debarker, log splitter,wood chipper, wood crusher, dryer, cooling and dusting machine, packing machine.

|

|

|

|

Advantages of the final product--- fuel pellets:

|

|

|

|

1.

|

High density

|

|

|

2.

|

High fuel value

|

|

|

3.

|

Low moisture

|

|

Related products

We have different type wood

and feed

pellet machine, if we know the raw material you use and the capacity you need, will give you the most professional recommendation, you also can click the below picture to learn more !!!

Packing & Delivery

Biomass Pellet Mill Machine Packing and Shipping

Packed in standard wooden case

Shipping by sea

Our service

|

1.

|

Pre-sales service:

|

|

1)

|

Sales person,project manager,technology engineer,accountant staff

|

|

2)

|

Professional responsing-team:would be very fast and exactly to send you offer

|

|

2.

|

Online / sale service:

|

|

1)

|

Super and solid quality

|

|

2)

|

Fastly delivery

|

|

3)

|

Standard export package or as your demand

|

|

3.

|

After-sale service:

|

|

1)

|

Assistance to build factory

|

|

2)

|

Repairing and maintenance if any problem occur in the warranty

|

|

3)

|

Installation and clerks training

|

|

4)

|

Spare and wearing parts for free or with big discount

|

|

5)

|

Any feedback of machines can be told us, and we will try our best to support you

|

|

4.

|

Other cooperation service:

|

|

1)

|

Technology knowledge share

|

|

2)

|

Factory building advising

|

|

3)

|

Any other machines (we don't have) help customer finding without any benefit

|

Hot Searches