- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

customizable

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

customizable

-

Marketing Type:

-

New Product 2024

-

Core Components:

-

membrane

-

Product Name:

-

Portable Membrane Nitrogen Enrichment Device

-

Rated Power:

-

<40 W

-

Oxygen Concentration:

-

30%+1.5

-

Oxygen Flow Rate:

-

4 L/min

-

Operating Sound:

-

<45 DB

-

Unit Weight:

-

0.9 Kg

-

Dimensions(L* W* H mm):

-

160 X 120 x75

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WOBO

-

Production Rate:

-

customizable

-

Voltage:

-

customizable

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

customizable

-

Marketing Type:

-

New Product 2024

-

Core Components:

-

membrane

-

Product Name:

-

Portable Membrane Nitrogen Enrichment Device

-

Rated Power:

-

<40 W

-

Oxygen Concentration:

-

30%+1.5

-

Oxygen Flow Rate:

-

4 L/min

-

Operating Sound:

-

<45 DB

-

Unit Weight:

-

0.9 Kg

-

Dimensions(L* W* H mm):

-

160 X 120 x75

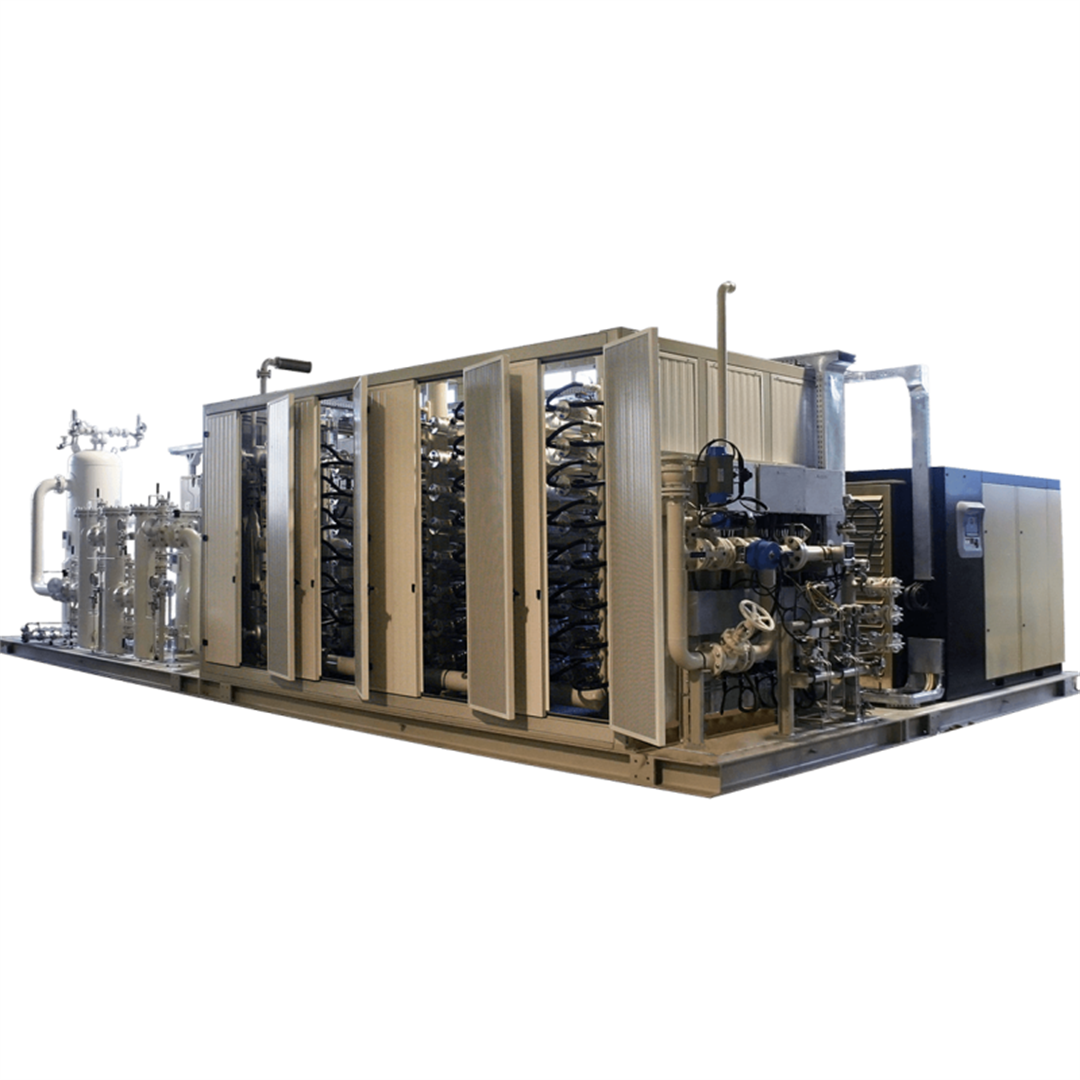

High Purity Nitrogen Separation Membrane Separation Equipment

China N2 Enriched Making Equipment 60Liters Skid-Mounted Membrane Nitrogen Generator for Welding

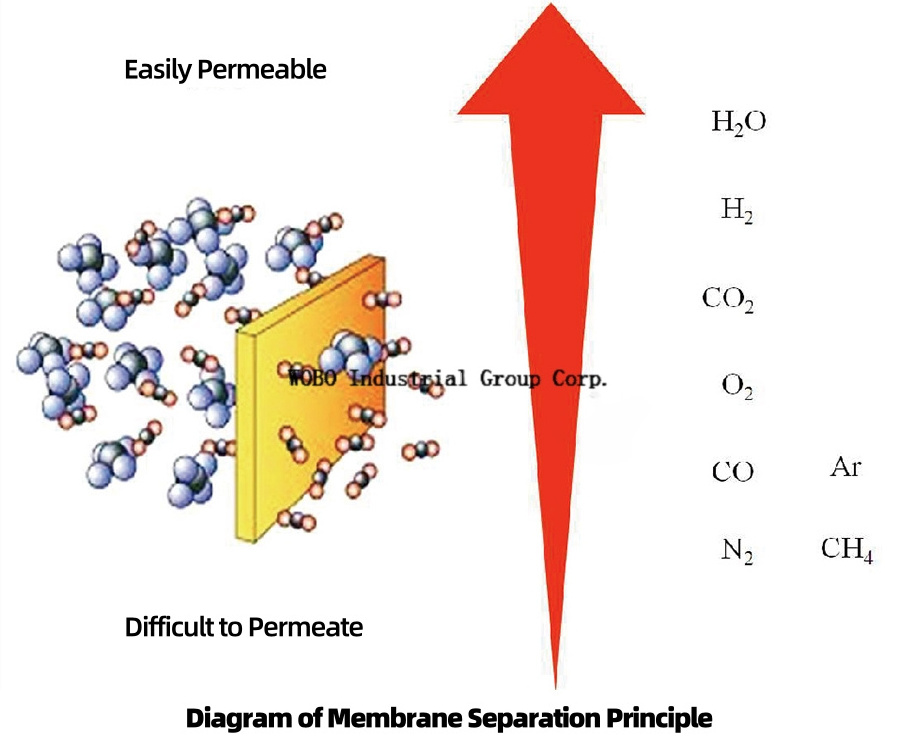

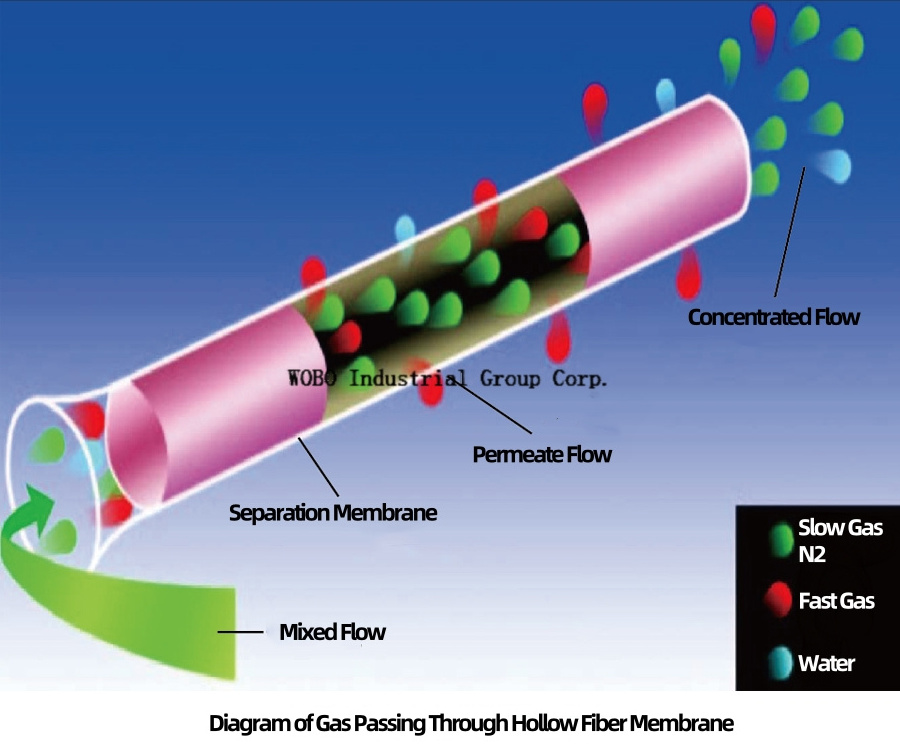

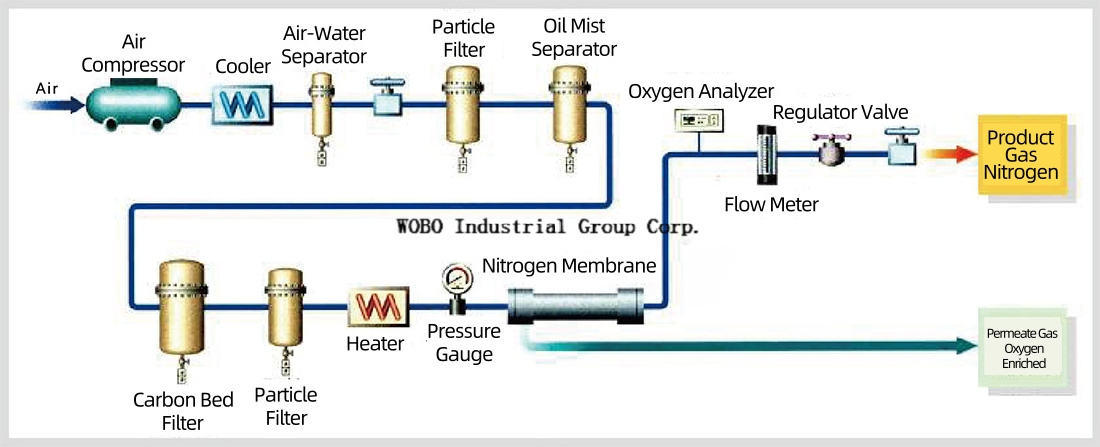

Technical Principle

Under the influence of the pressure difference on both sides of the membrane, nitrogen and oxygen in the air, due to their different solubility and diffusion coefficients in the membrane, result in water vapor and oxygen, with faster permeation rates, preferentially passing through the membrane to become oxygen-enriched gas. Meanwhile, nitrogen, with a slower permeation rate, accumulates on the retentive side, forming dry nitrogen-enriched gas.

Product Description

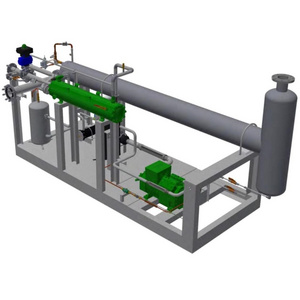

The Main Process Flow of The Membrane Nitrogen Generation System

|

Property

|

Range

|

|

|

Nitrogen Purity

|

85-99.9%

|

|

|

Nitrogen Production Capacity

|

0.5-5000 Nm³/h

|

|

|

Membrane Module Types

|

Flat Plate, Spiral-wound, Hollow Fiber

|

|

|

Membrane Material Types

|

Metal, Inorganic, Polymer

|

|

|

* Various Models/Size/OEM/ODM Can Be Supported.

|

|

|

Nitrogen enrichment system with membrane technology

Characteristics of performance and applications

●Capacity of nitrogen production: 0.5-5000Nm3/h

●Equipped with oxygen-removal system by chemical catalysis simultaneously resulting in the nitrogen purity of 99.9999%.

●No phase change during separation process. Low pressure lost of nitrogen

●Easy operation, no moving parts, stable and continuous working without maintenance

●Flexible operation. Adjustable nitrogen concentration and flow rate tailored to customer's needs

●Easy and quick start/shutdown. Stable product gas within several minutes after start

●Low operating cost, small occupied area. Long working life of membrane modules

●Supply oxygen-enriched gas with maximum purity of 50% at the same time

The Main Application Areas of Oxygen Enrichment

Project Case

Hot Searches