- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SCK

-

Voltage:

-

110V/220V

-

Power:

-

2.5KW

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

98

-

Product name:

-

compact magnetron sputtering system

-

Magnetron Sputtering Head:

-

3 pieces

-

Vacuum chamber:

-

300 mm Dia. x 300 mm

-

Target size requirement:

-

2" diameter

-

Source Power:

-

1DC/1RF

-

Sample holder size:

-

140 mm Dia

-

Rotation speed:

-

1 - 20 rpm adjustable

-

Application:

-

lab vacuum Glove box

-

DC source:

-

500W

-

RF source:

-

300W

Quick Details

-

Machine Type:

-

coating, Coating Equipment

-

Marketing Type:

-

2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SCK

-

Voltage:

-

110V/220V

-

Power:

-

2.5KW

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

98

-

Product name:

-

compact magnetron sputtering system

-

Magnetron Sputtering Head:

-

3 pieces

-

Vacuum chamber:

-

300 mm Dia. x 300 mm

-

Target size requirement:

-

2" diameter

-

Source Power:

-

1DC/1RF

-

Sample holder size:

-

140 mm Dia

-

Rotation speed:

-

1 - 20 rpm adjustable

-

Application:

-

lab vacuum Glove box

-

DC source:

-

500W

-

RF source:

-

300W

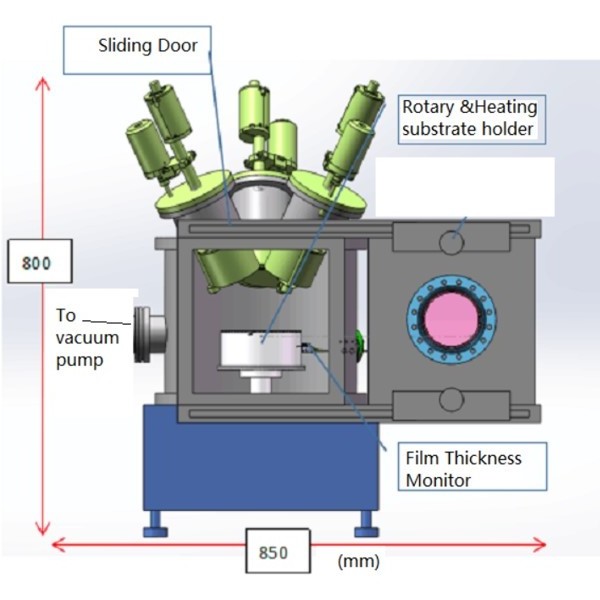

high quality magnetron sputtering Coater in the glove box is suitable for perovskite battery film research

SCK-VTC-600-2HD-GB is a compact magnetron sputtering system with dual 2" target sources in the glovebox. The system will provide the environments of oxygen-free and humidity-free (<1 PPM ) for coating and processing air-sensitive thin film. One DC source for coating metallic film, and the other RF source for coating non-metallic material. This coating system is designed for coating both single or multiple film layers for a wide range of materials, such as alloy, ferroelectric, semiconductor, ceramic, dielectric, optical, PTFE, etc.

.

(factory supply,Support customization, including accessories and consumables, please contact our staff for details.)

specifications

|

Glovebox with Purification |

Chamber dimension: 1200 mm L x 740 mm W x 900 mm H, made of stainless steel. Hinged type front door for loading devices and sample easily Automic purging function for quickly removing O2 and H2O before recirculating purification Automatic regeneration function is built-in in the control panel High-quality purification system ensures O2 and H2O below 1 PPM Two Antechambers for large and small samples delivery |

|

Sputtering Coater |

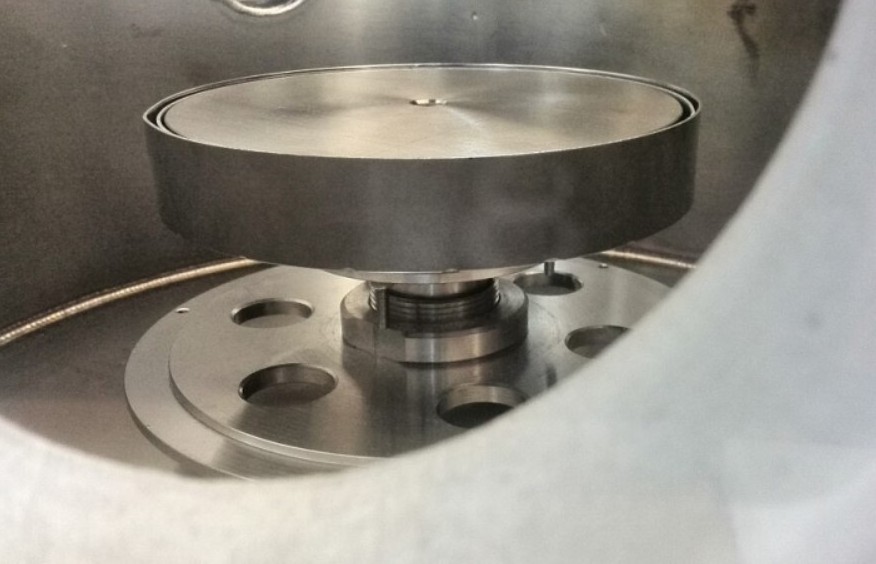

The coater is recessed in the bottom of the glovebox with air-tight flange. Two 2" magnetron plasma sputtering guns are installed on the top of the cover, which is a hinged type door. Two sputtering power sources are integrated into one control unit and are placed outside the glovebox. One DC source: 500 W power for coating metallic materials One RF source: 300 W power, 13.56 MHz frequency for coating non-conductive materials |

|

Input Power |

Single-phase110V/ 220 VAC 50 / 60 Hz 2500 W (including a vacuum pump and water chiller) |

|

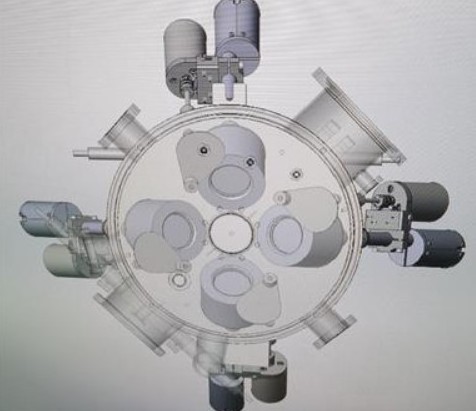

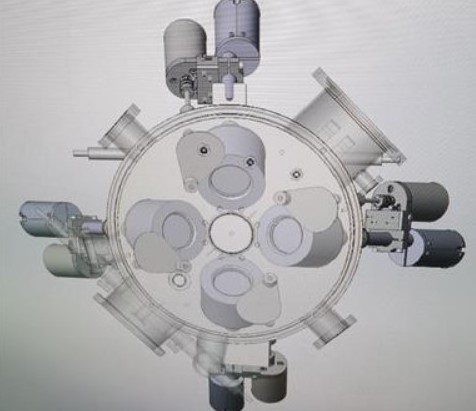

Magnetron Sputtering Head |

Two 2" Magnetron Sputtering Heads with water cooling jackets and shutters are included One is connected to DC source for coating metallic materials The other one is connected to the RF source for non-conductive materials Target size requirement: 2" diameter Thickness range: 0.1 - 5 mm for both metallic and non-conductive targets (including the backing plate) |

|

Vacuum Chamber |

Vacuum chamber: 300 mm Dia. x 300 mm Height, made of stainless steel Viewport: Two pieces of 100 mm Dia. glass. One fixed; one detachable for cleaning and replacement Hinged type lid with pneumatic power pole allows easy target change |

|

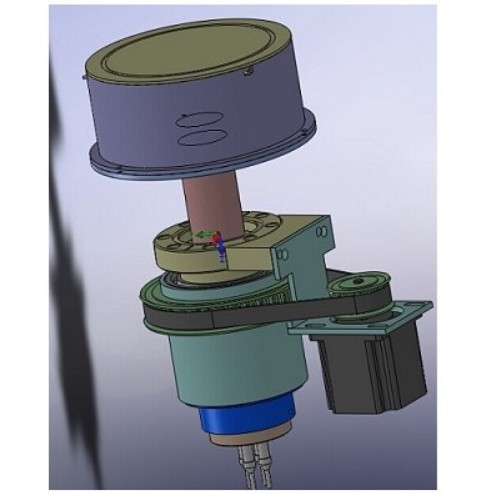

Sample Stage |

The sample holder is a rotatable and heatable stage made of the ceramic heater with copper cover Sample holder size: 140 mm Dia. for. 4" wafer max Rotation speed: 1 - 20 rpm adjustable for uniform coating The holder temperature is adjustable from RT to 500 ° C max (2 hr max) with accuracy +/- 1.0 ° C via a digital temperature controller |

|

Gas & Flow Control |

Two precision mass flow controllers (MFC) are installed to allow inlet of two types of gases Flow rate: 0 – 200 mL/min & 0 - 100ml/min adjustable on the touch screen control panel Air inlet valve is installed for vacuum release 5N purity Ar gas is required for operating the coating system in the glovebox. |

|

Vacuum Pump |

240 L/m Double Stage Rotary Vacuum Pump with Exhaust Filter is included to control chamber pressure No turbopump is necessary for the coating system in the glovebox because the purification system can reduce the argon gas to less than 1 ppm level, which is much better than turbopump |

|

Water Chiller |

One digital temperature-controlled recirculating water chiller is included. Refrigeration range: 5~35 ° C Flow rate: 16 L/min Pump pressure: 14 psi |

|

Film Thickness Monitor |

Precise quartz Film Thickness Monitor is optional, which is used for in-situ thickness measurement. Accuracy up to 1Å Precision Thin Film & Coating Analysis Systems - EQ-TFMS-LD is available at an extra cost Various 2 ” oxide and metallic targets are available upon request at extra cost. Silver epoxy and copper backing plates can be ordered at SCK |

|

Warranty |

Lifetime support 2-years limited standard warranty (extend the warranty to 5 years at an extra cost) |

|

Whether to support customization |

yes |

More detailed pictures

1. Reply your inquiry in 24 working hours.

2. Experienced staffs answer all your questions in fluent English.

3. Customized design is available.

4. Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

5. Professional factory : We are manufacturer, specializing in laboratory equipment.