- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YOUBOND

-

Weight:

-

8000 KG

-

Dimension(L*W*H):

-

15.5*2.4*2.4m/15.7*2.6*2.4m

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

high accuracy laminating machine

-

Feature:

-

corrugated paper laminating machine

-

Speed:

-

12000sheet/hour

-

Max sheet:

-

1450*1450mm/1650*1650mm

-

Min sheet:

-

400*400mm

-

Top paper thickness:

-

120-500g

-

Marketing Type:

-

New Product 2020

Quick Details

-

Voltage:

-

380V/50HZ

-

Power:

-

22KW -25KW

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YOUBOND

-

Weight:

-

8000 KG

-

Dimension(L*W*H):

-

15.5*2.4*2.4m/15.7*2.6*2.4m

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

high accuracy laminating machine

-

Feature:

-

corrugated paper laminating machine

-

Speed:

-

12000sheet/hour

-

Max sheet:

-

1450*1450mm/1650*1650mm

-

Min sheet:

-

400*400mm

-

Top paper thickness:

-

120-500g

-

Marketing Type:

-

New Product 2020

High speed servo type laminating machine

Features:

1.Quick set up when input the paper size and flute type.

2.Servo compensation positioning, automatic tracking system

3.Cardboard+corrugated paper, cardboard+cardboard, double function.

Specification of the YB-1450-1650H high speed laminating machine and flip flop stacker

| MODEL | YB-1450H | YB-1650H |

| Max Sheet | 1450×1450mm(57''x*57'') | 1650×1650mm (64''x*64'') |

| Min Sheet | 380×350mm | 380 × 350 mm |

| Top Paper Thickness | 150-500g | 150-500g |

| Botton Sheet Thickness |

A,B,C,E,F flute,4 ply corrugated paper(AA,AB,BB) cardboard above 300 GSM |

|

| Max Speed | 150m/min | 150m/min |

| Fitting Precision | ±1mm | ±1mm |

| Air consuption | 1.2m3/min | 1.2m3/min |

| Measurement | 23.6×2.7×3M | 23.6×2.9×3M |

| Machine Power | 30KW | 32KW |

Remarks: The top sheet could be the printed color sheet, filmed paper and uv varnished and paper from offset printing machine.

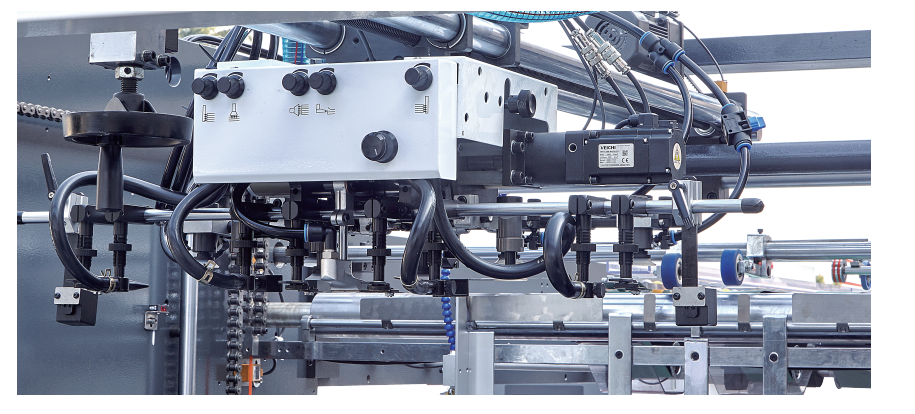

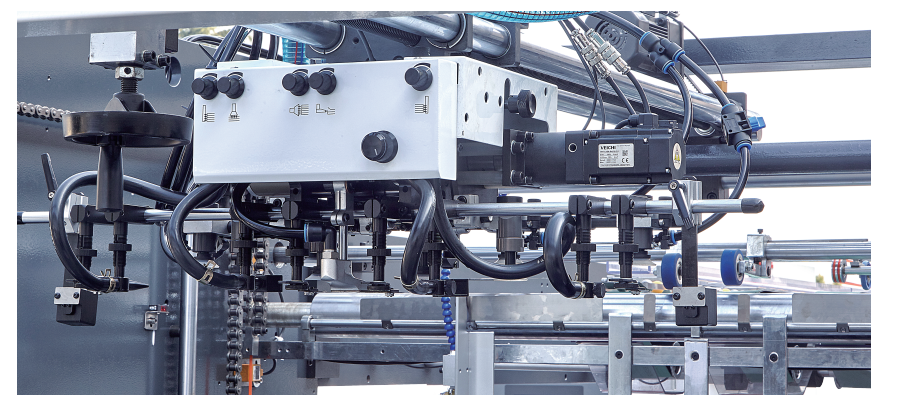

1.Top Feeder Part

equipped with high speed shaftless feeder which controlled by the servo motor, both paper lifting and feeding nozzle can freely adjust angle to the paper, to ensure that whether thick or thin paper can be delivered rapidly and smoothly

Side lay (second positioning) ensure the side alignment

Advantages: Whatever direction the top sheet goes, the side-pulling balls will make the sheet go in one line.

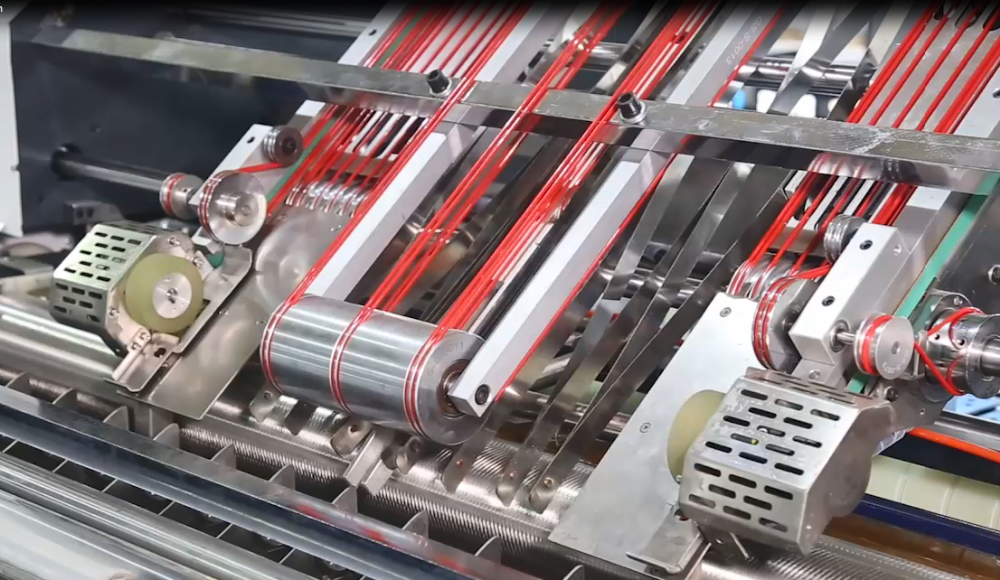

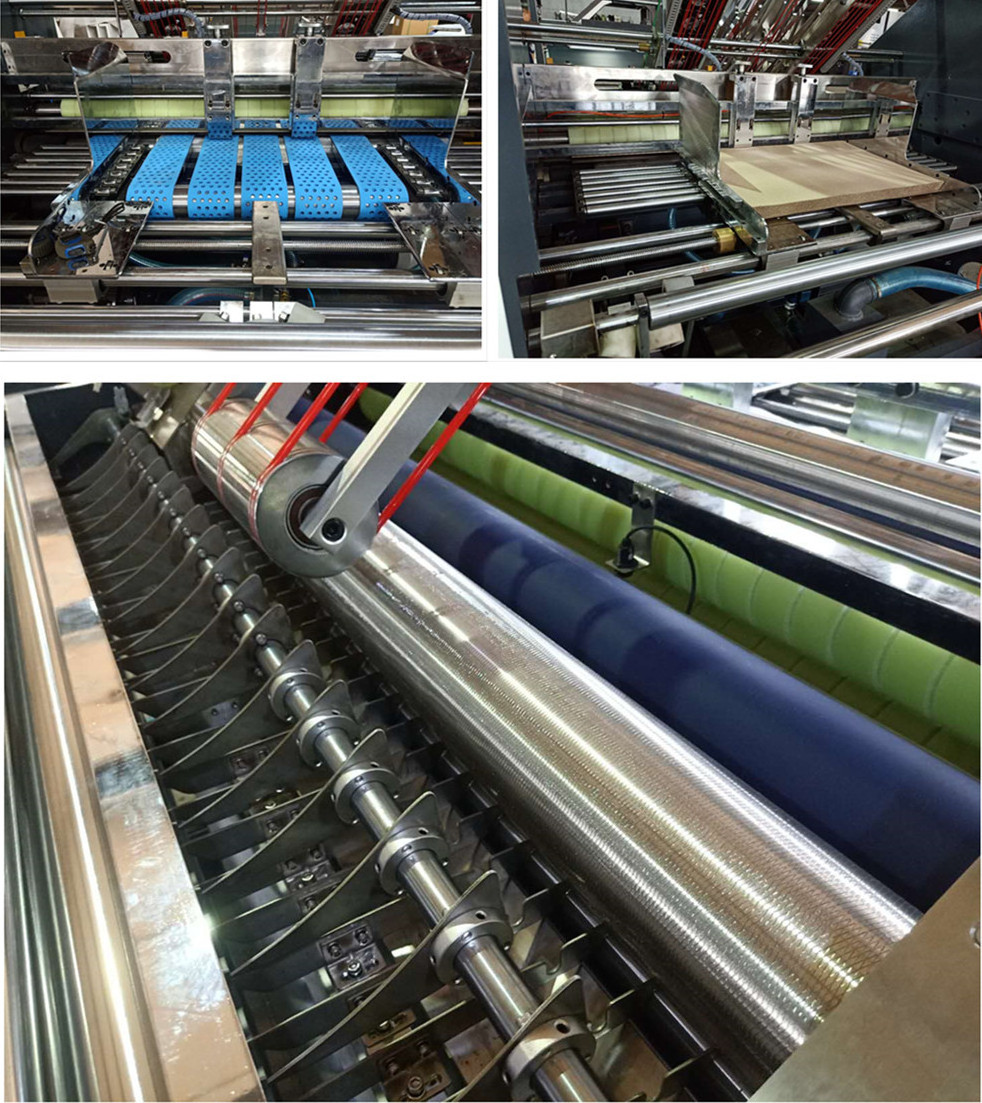

2.Bottom feeding and laminating part

Imported brand belt, good suction ability for the bottom sheet feeding.

Stainless steel material roller,never rust, guarentee the amount of glue is even

Servo motor that controll the top sheet Sheet mass detector

3.Electrical part

Famous brand electrical component ensure machine stability, high efficiency and low failure. Using man-machine display interface and PLC combination, display all the information, such as warning, error detect, failures,and operating speed, etc

4. Sheet pressing part

Slope type of the pressing convoyer, humanized design to save effort for the operator collecting the sheets.

Pressing wheels Collecting table

When machine arrives at the customers factory, we could dispatch the engineer to the customers factory for the installation and trainning, meanwhile, when customer has the questions, customer could contact us online, our service team will always there for customers service.

We have professional sales and well educated after-sales service team.

If you have any inquiry, please feel free to contact us, it would be our pleasure to help you and make your task a lot easier!