- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Changyi

-

Dimension(L*W*H):

-

depends on model

-

Weight:

-

12000 KG

-

Product Name:

-

Jaw Crusher

-

Color:

-

Customerized

-

Advantage:

-

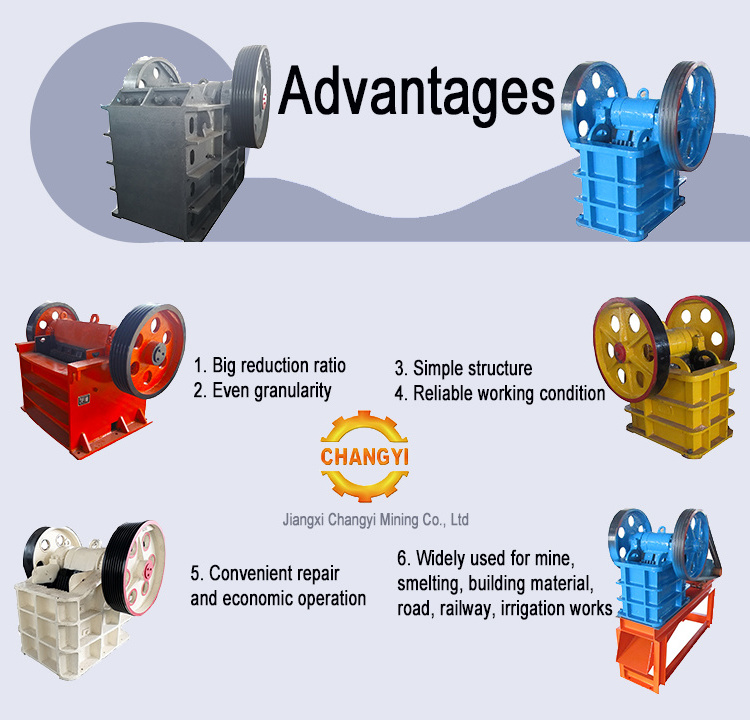

High Effiency

-

Features:

-

High Processing Capacity

-

Installation:

-

Technical Guidance

-

Quality:

-

Superior

-

Price:

-

Favorable

-

Used for:

-

Fine Crushing Process

-

After sale Service:

-

Technology Support

-

Certification:

-

ISO 9001

Quick Details

-

Application:

-

Mining

-

Capacity(t/h):

-

Max.1000t/h

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Changyi

-

Dimension(L*W*H):

-

depends on model

-

Weight:

-

12000 KG

-

Product Name:

-

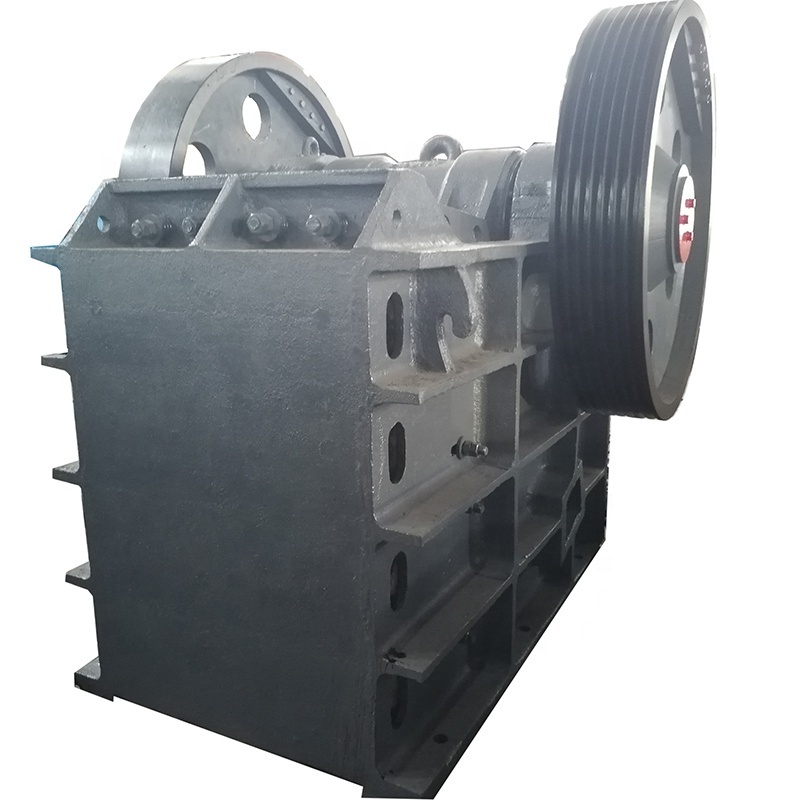

Jaw Crusher

-

Color:

-

Customerized

-

Advantage:

-

High Effiency

-

Features:

-

High Processing Capacity

-

Installation:

-

Technical Guidance

-

Quality:

-

Superior

-

Price:

-

Favorable

-

Used for:

-

Fine Crushing Process

-

After sale Service:

-

Technology Support

-

Certification:

-

ISO 9001

Product Description

Jaw crusher is suitable for crushing a variety of soft and hard ores and rocks, whose largest compression resistance is under 320 MPa. Maximum size of to be fed materials must be less than what is required according to the maximum specification of technical parameters. Jaw crusher is mainly used for secondary and fine crushing of mid hardness ores and rocks in metallurgical industry, mining, chemistry, cement making industry, construction, refractory, pottery, porcelain industry, etc. All models of stone jaw crushers are available according to your different fineness requirements.

Working Principle

Jaw crusher electric motor drives the belts and the belt wheel make the movable jaw up and down through the eccentric shaft. When the movable jaw descends, the angle between the fixed jaw and the movable jaw becomes smaller, and the materials can be crushed. When the angle becomes bigger, the crushed materials are discharged from the crushing cavity.

Details Images

Technical Parameters

|

Model

|

Max feeding size

(mm)

|

Capacity

(t/h)

|

Eccentric shaft rotating speeding

(r/min)

|

Weight

(t)

|

|

PE-150×250

|

125

|

1-3

|

250

|

0.8

|

|

PE-830×1060

|

650

|

150-336

|

250

|

31

|

|

PEX-300×1300

|

250

|

16-105

|

300

|

16

|

Note: Data only for reference, according to customer requirements for design and production.

Hot Searches