- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

THD

-

Voltage:

-

AC 110V/220V

-

Power:

-

50

-

Dimension(L*W*H):

-

64*46*98cm

-

Weight (KG):

-

28

-

Hopper Diameter:

-

37.5 cm

-

Hopper Height:

-

54 cm

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

None

Quick Details

-

Machine Type:

-

Paint machine, Spray Booths

-

Core Components:

-

Static generator

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

THD

-

Voltage:

-

AC 110V/220V

-

Power:

-

50

-

Dimension(L*W*H):

-

64*46*98cm

-

Weight (KG):

-

28

-

Hopper Diameter:

-

37.5 cm

-

Hopper Height:

-

54 cm

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

None

Products Description

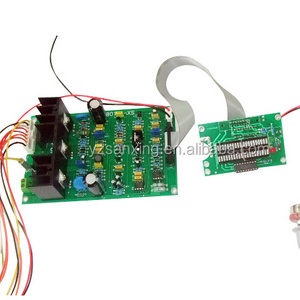

Manual Electrostatic Spray Paint Machine

The spray equipment uses an automatic current feedback circuit and adds a pulse control

circuit. The gas control part adopts two-stage gas source filtration, voltage regulation and air pressure adjustment, all designed

as preset adjustments. The powder output is more uniform, the atomization is better, and the dead angle is much better.

circuit. The gas control part adopts two-stage gas source filtration, voltage regulation and air pressure adjustment, all designed

as preset adjustments. The powder output is more uniform, the atomization is better, and the dead angle is much better.

Manual Electrostatic Spray Paint Machine:

The Technical Parameters of Manual Electrostatic Spray Paint Machine

|

Input Voltage

|

AC220V±10%

|

|

Frequency

|

50Hz

|

|

Input Power

|

50W

|

|

Output Voltage

|

21VDC

|

|

Out Current

|

0-200uA

|

|

Maximum output voltage

|

0-100KV

|

|

Water vapor content of compressed air

|

1.3g/m³

|

|

Oil vapor content of compressed air

|

<0.01g/m³

|

Details Images

Our Advantages

1. The workpiece can be painted at room temperature

2. High powder utilization rate, up to 95%

3. The coating film is thin and uniform, smooth and without sag

4. On the sharp edges and rough surface of the workpiece, a continuous and smooth

coating can be formed.

5. Easy to realize industrialized line production

6. It is more environmentally friendly than spray-paint, but the fireproof and

explosion-proof grades are slightly lower.

7. The social and economic benefits are significant, the cost is 20~30% lower than the

solvent process, and the batch production cycle is shortened by 20 days.

2. High powder utilization rate, up to 95%

3. The coating film is thin and uniform, smooth and without sag

4. On the sharp edges and rough surface of the workpiece, a continuous and smooth

coating can be formed.

5. Easy to realize industrialized line production

6. It is more environmentally friendly than spray-paint, but the fireproof and

explosion-proof grades are slightly lower.

7. The social and economic benefits are significant, the cost is 20~30% lower than the

solvent process, and the batch production cycle is shortened by 20 days.

Appliation

Manual Electrostatic Spray Paint Machine can used for

Metal Pieces, all series Steel Pipe, Aluminum Profiles, Wheels, Chairs, Tables, Doors, Railings, Shutter Doors, Auto parts, Bicycle Accessories, etc.

Hot Searches