- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Customized

-

Weight:

-

25000 KG

-

Machinery Function:

-

Making frozen vegetables and frozen food

-

Output product name:

-

Frozen French Fries

-

Application:

-

Making Half Fried Potato frozen french fries

-

Output:

-

2000kg/hr

-

French fries size:

-

6~20mm

-

Energy:

-

Electricity, gas, steam, diesel, etc.

-

Product name 1:

-

Potato peeling machine

-

Product name 2:

-

Potato cutting machine

-

Product name 3:

-

French fries blanching machine

-

Product name 4:

-

French fries half frying machine

-

Product name 5:

-

French fries Deoiling Cooling Machine

-

Product name 6:

-

French fries IQF freezer Machine

Quick Details

-

Brand Name:

-

CNZTM

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380V/50Hz

-

Power:

-

Customized

-

Weight:

-

25000 KG

-

Machinery Function:

-

Making frozen vegetables and frozen food

-

Output product name:

-

Frozen French Fries

-

Application:

-

Making Half Fried Potato frozen french fries

-

Output:

-

2000kg/hr

-

French fries size:

-

6~20mm

-

Energy:

-

Electricity, gas, steam, diesel, etc.

-

Product name 1:

-

Potato peeling machine

-

Product name 2:

-

Potato cutting machine

-

Product name 3:

-

French fries blanching machine

-

Product name 4:

-

French fries half frying machine

-

Product name 5:

-

French fries Deoiling Cooling Machine

-

Product name 6:

-

French fries IQF freezer Machine

2000kg/hr IQF Half Fried Frozen French Fries Production Line

1.-2000kg/hr Half Fried Frozen French Fries Production Line Introduction

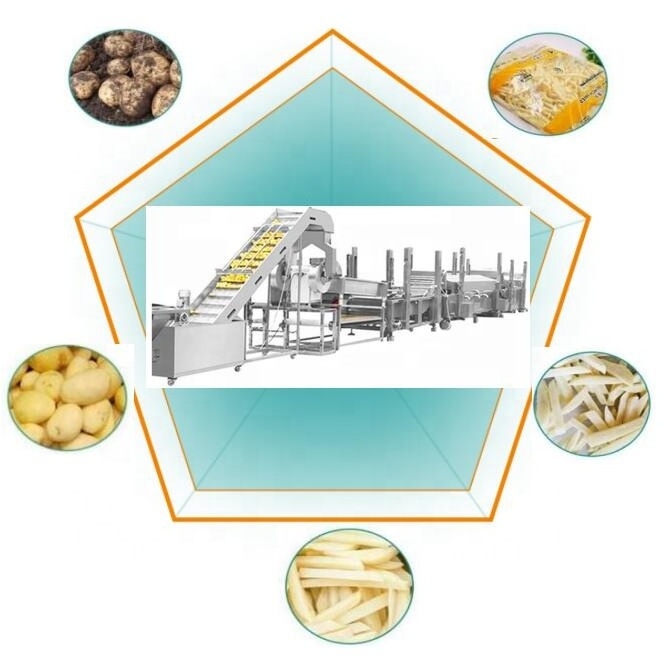

The Automatic IQF Frozen French Fries Production Line

consists of 1) potato washing and peeling machine, 2)french fries cutting machine, 3) french fries washing machine, 4) french fries blanching machine, 5) air drying machine, 6) continuous half frying machine, 7) deoiling and cooling machine, 8) IQF freezer, 9) packing machine,ect.

Some main equipment are guided in the picture following:

2.-Industrial Automatic Half Fried Potato Fries Making Machine Flow Chart

Size of the french fries:

8*8mm, 9*9mm, 10x10mm, 12*12mm

3.-Industrial Full Automatic Half Fried Frozen Potato Fries Making Plant

1) Potato Peeling Machine: works with spray water, hard brush and abrasive roller,1000~1500kg/hr.

2) French fries cutter: cutting peeled potato into sticks, size 6~20mm, 500~1000kg/hr.

3) Bubble Washing Machine: Remove starch of french fries.

4) French fries Blanching machine: for boiling and blanching to preserve color and fresh.

5) French fries drying machine: equipped with mesh belt and fans to remove the surface water.

6) Continuous frying machine: half fried in hot oil.

2) French fries cutter: cutting peeled potato into sticks, size 6~20mm, 500~1000kg/hr.

3) Bubble Washing Machine: Remove starch of french fries.

4) French fries Blanching machine: for boiling and blanching to preserve color and fresh.

5) French fries drying machine: equipped with mesh belt and fans to remove the surface water.

6) Continuous frying machine: half fried in hot oil.

7) Deoiling conveyor: Remove surface oil and cooling.

8) IQF Freezer: Making frozen french fries.

8) IQF Freezer: Making frozen french fries.

BENEFITS OF OUR FRENCH FRY PROCESSING LINE:

Performance & consistency

Productivity

Low waste & water use

24/7 reliability

Food safety

Capacity: 1000–2000 kgs/hr

Storage Guide for Frozen French Fries

At - 18°C until date printed on the packaging.

At - 12°C 1 month.

At - 6 °C 1 week.

Once defrosted do not refreeze!

4.-Industrial Full Automatic Frozen French Fries Making Line Production Field

Related Product

Certificates

Customer Photos & Reviews

Workshop

Shipping&Delivery

FAQ

Q1.Could we visit your factory to check the machine carefully and closely?

A:Welcome to our facotry,will provide machines testing service,face-face discussing,turnkey project design solution.

Q2.How long is your machine's guarantee time?

A:1 year without normal wear parts,machine itself life guaranteed.

Q3.If we have very special request for the complete production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q4.If we show you our layout of factory,can you help to design the whole process line?

A:Layout design service provided after received customer's factory layout size.

Q5.If we have samples of new products,can you help to analysis and design the machine?

A:Yes,our technical department can help to analysis,design and test the new products based on the specific requirements you provided.

Hot Searches