- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

10500*1000*1700mm

-

Power (kW):

-

15

-

Weight (KG):

-

3600 kg

-

Panel Feed Speed(m/min):

-

16m/min, 16m/min

-

Edge Thickness:

-

0.4 - 3 mm

-

Panel Thickness:

-

10 - 60 mm

-

Working Pressure:

-

6.5 bar

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Golden promise

-

Voltage:

-

220V 380V

-

Dimension(L*W*H):

-

10500*1000*1700mm

-

Power (kW):

-

15

-

Weight (KG):

-

3600 kg

-

Panel Feed Speed(m/min):

-

16m/min, 16m/min

-

Edge Thickness:

-

0.4 - 3 mm

-

Panel Thickness:

-

10 - 60 mm

-

Working Pressure:

-

6.5 bar

Products Description

PLC control system

1. Light touch PC computer display

2. Thin and thick edge banding,

can be operated by pressing the button

3. Temperature control function,

4. unit intelligent control

2. Thin and thick edge banding,

can be operated by pressing the button

3. Temperature control function,

4. unit intelligent control

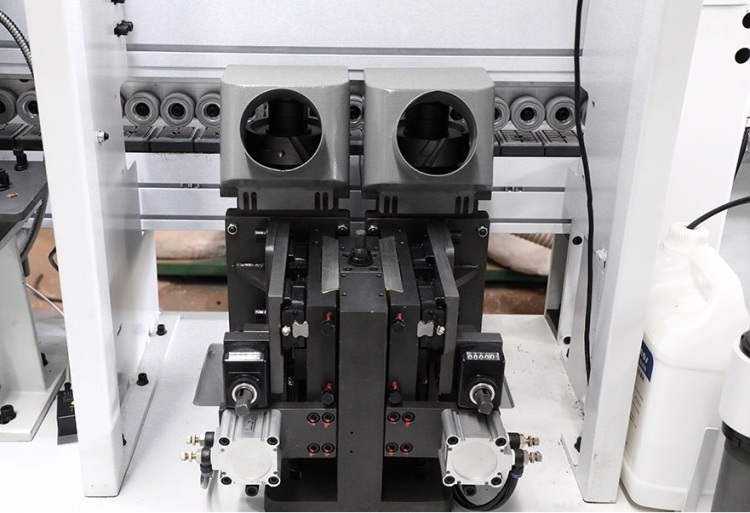

Six-wheel pressing device

The pressing unit makes the board and the edge banding fit together.The edge band and the

board stick more closely

board stick more closely

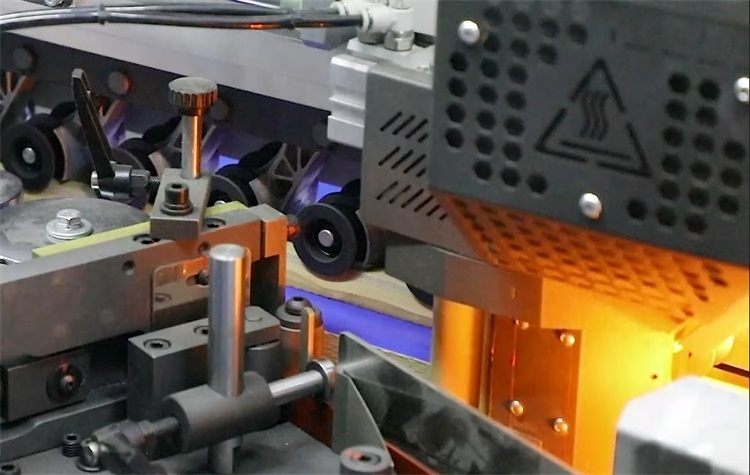

Front and rear alignment

SMC cylinder control, cut off the edge bands of

the front and rear sections of the board

after edge banding, the single guide rail is

designed at 45 degrees, more accurate and

more efficient,

and the addition of dust suction ports and

material baffles can effectively remove

waste materials

the front and rear sections of the board

after edge banding, the single guide rail is

designed at 45 degrees, more accurate and

more efficient,

and the addition of dust suction ports and

material baffles can effectively remove

waste materials

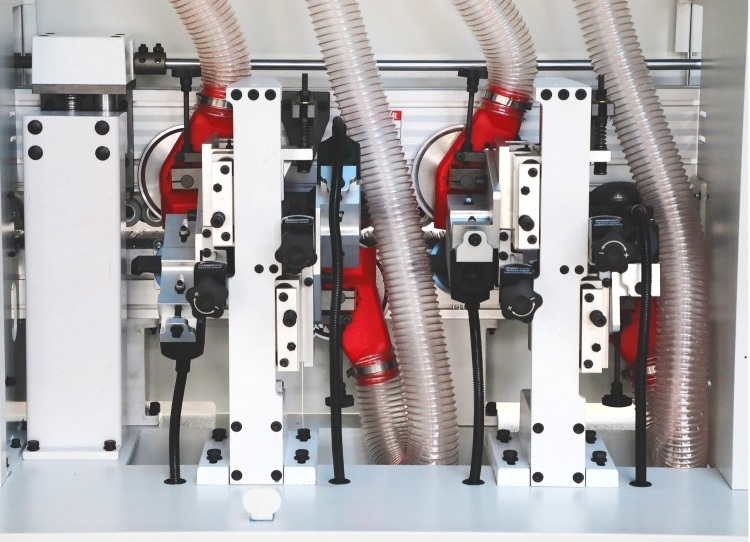

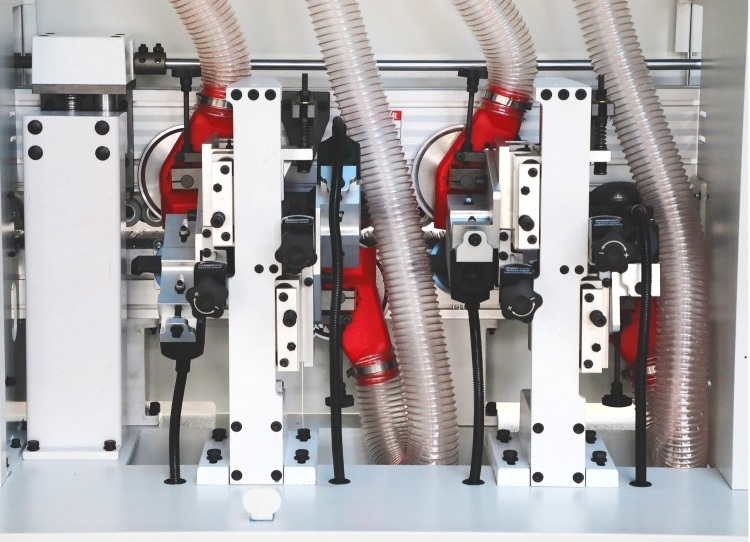

Rough trim Fone trim

Up and down high-speed repair device

(with digital meter adjustment display meter)

0.75kwX2 (independent high-frequency control,

with R2 repair 2)

(with digital meter adjustment display meter)

0.75kwX2 (independent high-frequency control,

with R2 repair 2)

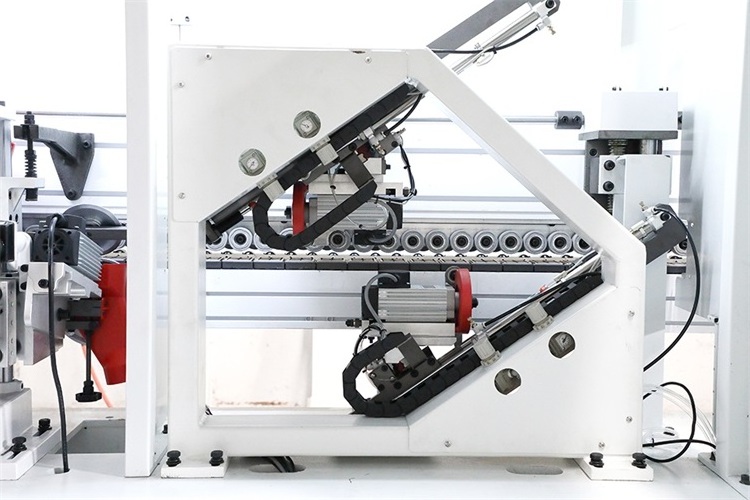

Track trimming

SMC cylinder control

High-speed tracking and trimming

device at both ends 0.37kw*2

(Independent high-frequency

control, equipped with 2 R2.5 trimming knives)

High-speed tracking and trimming

device at both ends 0.37kw*2

(Independent high-frequency

control, equipped with 2 R2.5 trimming knives)

Edge scraping

Scrape out arcs on the upper

and lower sides of the edge banding

after trimming to make the

edge banding effect more refined

With R2 scraper 2 pieces

and lower sides of the edge banding

after trimming to make the

edge banding effect more refined

With R2 scraper 2 pieces

Specifications

|

Mechanical index

|

Mechanical index

|

|

Model

|

EGC-6TKGP

|

|

Edge Thickness

|

0.4 - 3 mm

|

|

Panel Thickness

|

10 - 60 mm

|

|

Feed Speed

|

18m/22m/26m/min

|

|

Min Panel Length

|

60 mm

|

|

Min Panel Width

|

100mm 160 mm

|

|

Motor Power

|

15kw

|

|

Working Pressure

|

6.5 bar

|

|

Weight

|

3600kg

|

|

Packing Size

|

10500 x 1100 x 1750mm

|

FACTORY EQUIPMENT

PACKAGING&TRANSPORTATION

Q1. Are your trading company or factory?

A1. We are factory, we have professional R&D team. Our factory located in Lunjiao Town, Shunde Dist., Foshan, Guangdong, China.

Q2. What machine can you supply?

A2. Our main machines are computer beam saw, edge banding machine, cnc drilling machine, cnc router machine etc.widely used for

panel furniture production.

Q3. What is the payment term?

A3. T/T 30% in advance and balance before shipment, LC or by negotiation.

Q4. What is the delivery time?

A4. Normal 380V voltage is 15-30 days, other voltage is 30-45 days.

Q5. What is the guarantee?

A5. 12 months for the whole machine. Within 12 months under normal use and maintenance, if something is wrong with the machine,

you will get spare part for free. Out of 12 months, you will get spare parts at cost price.You will also get technical support and

service all the lifetime.

Q6. Can you support the pre-sales service before confirm the order?

A6. Yes ,you will get experienced pre-sales engineer to support, not only including machine and auxiliary selection but also

electrical ,air, machine layout in factory ,etc.

Q7. What is the after sales services?

A7. you will be able to get free training advice towards our machine in our factory. You will also get free suggestion and

consultation, technical support and service by online tools. We can also send our engineer to your factory, but need you take

charge of all travelling cost and labour cost.

A1. We are factory, we have professional R&D team. Our factory located in Lunjiao Town, Shunde Dist., Foshan, Guangdong, China.

Q2. What machine can you supply?

A2. Our main machines are computer beam saw, edge banding machine, cnc drilling machine, cnc router machine etc.widely used for

panel furniture production.

Q3. What is the payment term?

A3. T/T 30% in advance and balance before shipment, LC or by negotiation.

Q4. What is the delivery time?

A4. Normal 380V voltage is 15-30 days, other voltage is 30-45 days.

Q5. What is the guarantee?

A5. 12 months for the whole machine. Within 12 months under normal use and maintenance, if something is wrong with the machine,

you will get spare part for free. Out of 12 months, you will get spare parts at cost price.You will also get technical support and

service all the lifetime.

Q6. Can you support the pre-sales service before confirm the order?

A6. Yes ,you will get experienced pre-sales engineer to support, not only including machine and auxiliary selection but also

electrical ,air, machine layout in factory ,etc.

Q7. What is the after sales services?

A7. you will be able to get free training advice towards our machine in our factory. You will also get free suggestion and

consultation, technical support and service by online tools. We can also send our engineer to your factory, but need you take

charge of all travelling cost and labour cost.

Hot Searches