- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

RFM

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

7m*1.3m*1.3m

-

Weight:

-

7 kg

-

Warranty:

-

1 year

-

name:

-

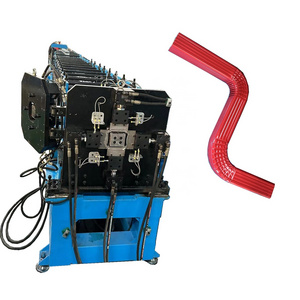

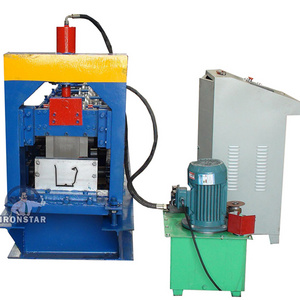

Downpipe Cold Roll Forming Machine

-

roller material:

-

Cr12

-

shaft material:

-

#45 steel

-

control system:

-

PLC

-

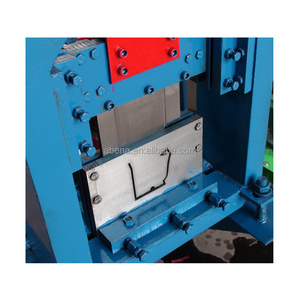

blade material:

-

Cr12

-

transport:

-

chain

-

thickness:

-

0.3-0.mm

-

forming steps:

-

12 steps

-

trade type:

-

manufacturer

-

color:

-

according your request

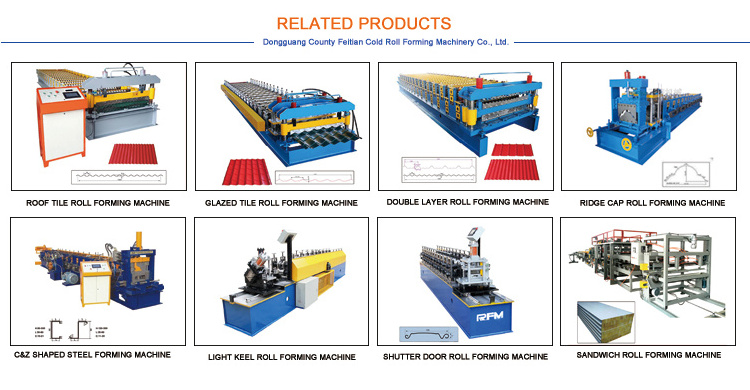

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

10-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

RFM

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

7m*1.3m*1.3m

-

Weight:

-

7 kg

-

Warranty:

-

1 year

-

name:

-

Downpipe Cold Roll Forming Machine

-

roller material:

-

Cr12

-

shaft material:

-

#45 steel

-

control system:

-

PLC

-

blade material:

-

Cr12

-

transport:

-

chain

-

thickness:

-

0.3-0.mm

-

forming steps:

-

12 steps

-

trade type:

-

manufacturer

-

color:

-

according your request

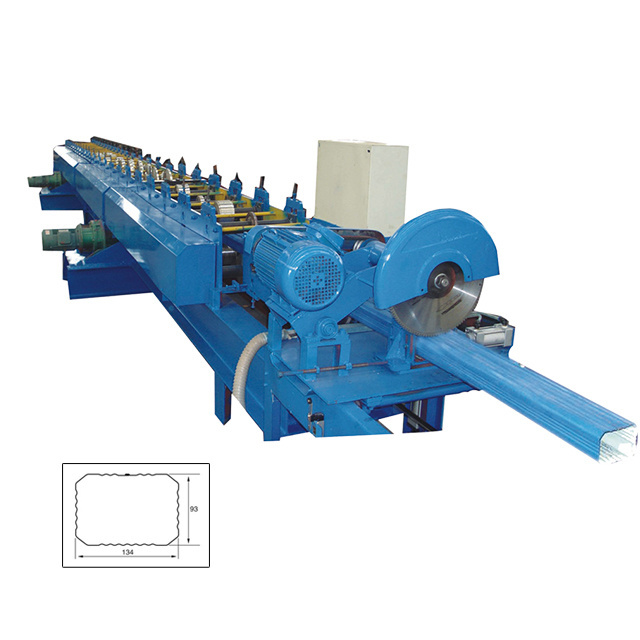

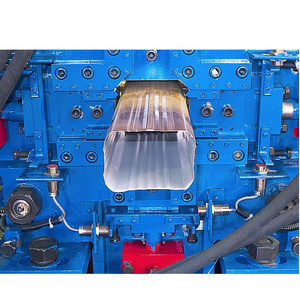

Aluminium Downspout / Steel Roofing Metal Water Rain Gutter Roll Forming Making Machine

Advantages:

♥ In Botou, we are the first to do pressure roll forming machine export business

♥ As a manufacturer we are specialized in all kinds of roll forming machine.

♥ Good experience of 20 years to make roll forming machine.

♥ Good experience for export more then 40 countries.

♥ Provide best price,good quality and fast delivery.

De-coiling →feedinig→forming → cutting →product

Parameter

1>Suitable material to process:GI&PPGI

2>Thickness of plate:0.3-0.8mm

3>Productivity:8-15m/min

4>Rollers:23rows

5>Diameter of the roller:56mm

6>Dimensions:major structure:10*1.2*1m

Decoiler :

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Inner diameter:350-450mm

Outer diameter:450mm

Coil width:300mm

Capacity:1.5T

Run out table :

1 set with 3 meter’s long.

PLC control station

Usage: Automatic length and quantity measurement.

Screen: touch screen

Frequency:Delta

PLC control

PLC:Delta

Hydraulic oil pump

Advanced hydraulic system from Taiwan

Usage: It is used to provide power for cutting devices.

Power: 3kw