- Product Details

- {{item.text}}

Quick Details

-

Power:

-

5KW-20KW

-

Weight:

-

600 KG

-

Dimension(L*W*H):

-

3000x1200x2000mm

-

Product name:

-

Horizontal Autoclave Sterilizer

-

Sterilizing way:

-

Water Spray/Steam

-

Capacity:

-

120 - 1000Kg

-

Material:

-

SUS304

-

MOQ:

-

1SET

-

MAX Working temperature:

-

143℃

-

WORK PRESSURE:

-

0.30Mpa

-

Adjustment of Temperature:

-

available

-

Certification:

-

CE ISO

-

package:

-

Standard Wooden Case

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

XINLONGJIA

-

Voltage:

-

380v-480v/50-60hz/1-3Phase

-

Power:

-

5KW-20KW

-

Weight:

-

600 KG

-

Dimension(L*W*H):

-

3000x1200x2000mm

-

Product name:

-

Horizontal Autoclave Sterilizer

-

Sterilizing way:

-

Water Spray/Steam

-

Capacity:

-

120 - 1000Kg

-

Material:

-

SUS304

-

MOQ:

-

1SET

-

MAX Working temperature:

-

143℃

-

WORK PRESSURE:

-

0.30Mpa

-

Adjustment of Temperature:

-

available

-

Certification:

-

CE ISO

-

package:

-

Standard Wooden Case

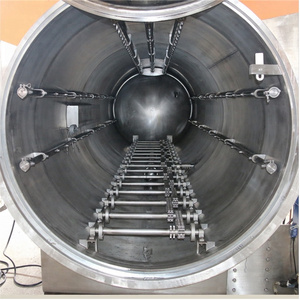

Product Display

XINLONGJIA Automatic

Water Spray Sterilizer Retort

This retort is perfectly suited for food sterilization. The Sterifood static is fitted with a powerful pump, for shorter and more homogeneous cycles. All the products inside the autoclave get the same thermal treatment, regardless of their position. The reduced cycle time also ensures better results.

Water sprays running over the entire shell length intensely mix the steam and water and create a homogeneous temperature distribution that results in a uniform process throughout the retort. Indirect, sterile cooling via a plate heat exchanger saves water and eliminates the need for water treatment chemicals.

1. The sterilized water is preheated in the hot water tank to the required temperature for sterilization (excluding multi-stage sterilization), which shortens the sterilization operation time and improves work efficiency.

2. The working medium water used in the sterilization process can be recycled, saving energy, time, manpower and resources, and reducing production costs.

3. Unidirectional water flow exchange method, with uniform temperature and no dead corners.

4. Fully automatic control system, multiple sterilization formulas can be stored in the computer. The entire sterilization process can be automatically controlled by a computer to complete operations (except for entering and exiting goods and switching pot doors).

5.Measure Fvalue function.

Working Process

Superheated water contained in the storage vessel allows for a short come-up time.

Hot water envelops the containers thus even temperature penetration into the products from all sides.

Optimized water circulation system guarantees homogenous temperature distribution.

Less stress on the containers achieved by the buoyancy effect from immersing the load in water, such as semi-rigid trays, pouches etc.

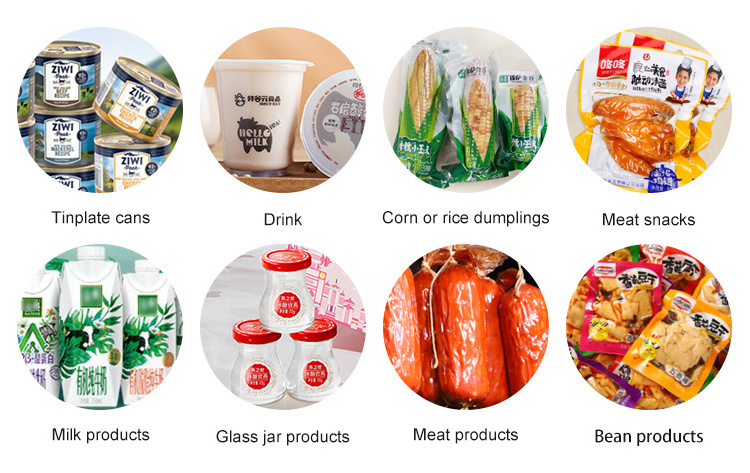

Rotary agitation function is available, perfect for products of high viscosity, such as condensed milk, flavored milk in plastic bottles, canned corn which need End-over-end rotation for forced convection or prevent burning on the container walls during heating.

In a Water Immersion process these steps are:

1.Prepare Tank (Water Heating)

2.Come Up Fill (A Sterilization Step)

3.Come Up (A Sterilization Step)

4.Cook (A Sterilization Step)

5.Pressure Cool Fill

6.Pressure Cool

7.Atmospheric Cool

8.Drain

|

Model

|

1000#

|

1200#

|

|

|

|

||||

|

Cylinder length(mm)

|

2400

|

2700

|

3600

|

4000

|

4500

|

||||

|

Total length(mm)

|

4200

|

4600

|

5600

|

6000

|

6600

|

||||

|

Total width(mm)

|

1600

|

1900

|

1900

|

1900

|

1900

|

||||

|

Total height(mm)

|

2800

|

3100

|

3100

|

3100

|

3100

|

||||

|

Volume(㎡)

|

2.2

|

3.4

|

4.6

|

5.0

|

5.5

|

||||

|

Pot body thickness(mm)

|

4

|

5

|

5

|

5

|

5

|

||||

|

Installed power(kw)

|

7

|

13

|

13

|

13

|

13

|

||||

|

Gas consumption(kg/Pot number)

|

115

|

200

|

255

|

280

|

300

|

||||

|

power consumption(kw/h)

|

5

|

9

|

9

|

9.5

|

10

|

||||

|

Design Press(Mpa)

|

0.35

|

0.35

|

0.35

|

0.35

|

0.35

|

||||

|

Design Temperature(℃)

|

147

|

147

|

147

|

147

|

147

|

||||

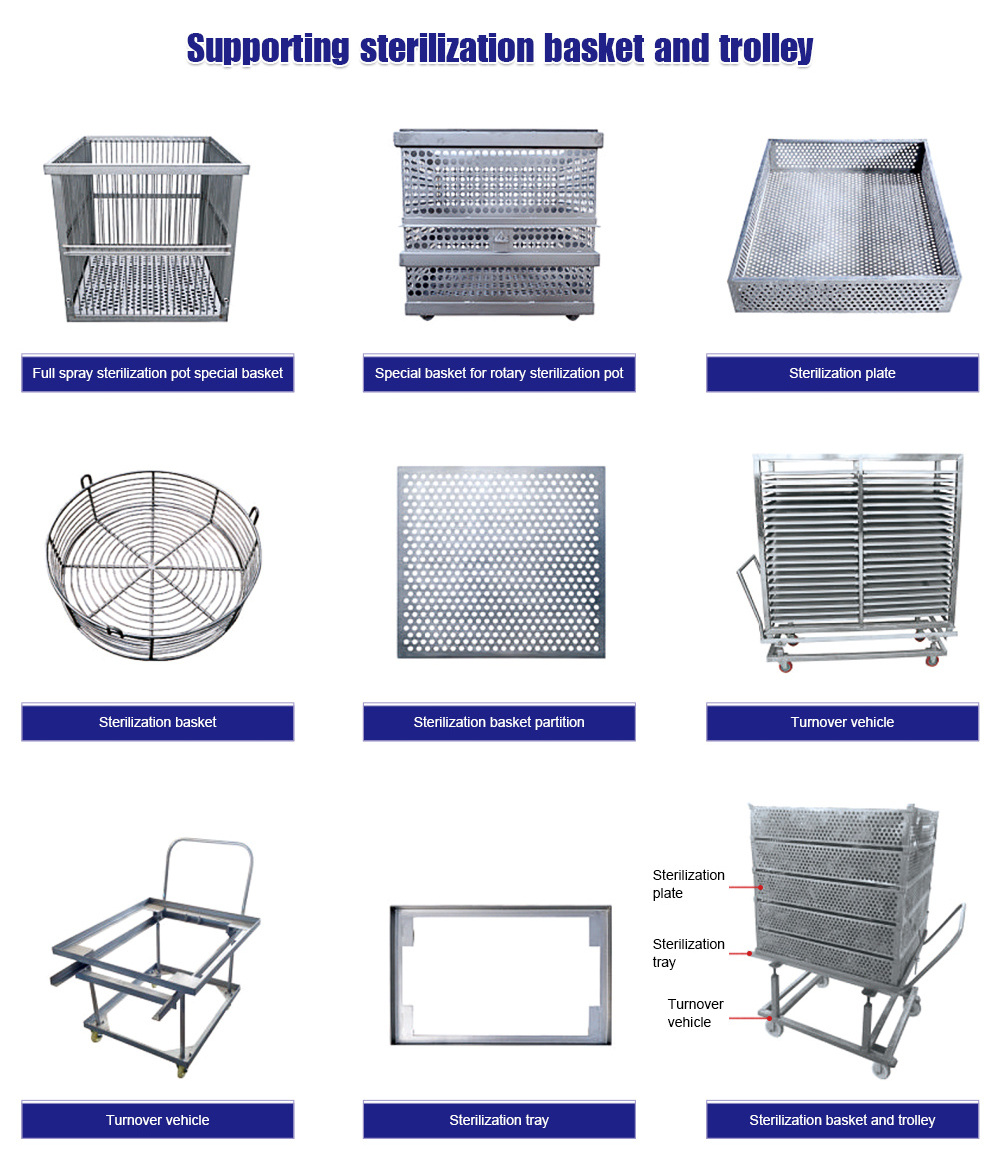

Auxiliary Equipment

|

Model

|

1000#

|

1200#

|

|

|

|

|||

|

Cylinder length(mm)

|

2400

|

2700

|

3600

|

4000

|

4500

|

|||

|

Air compressor(㎡/min/Mpa)

|

0.8/1.0

|

1.0/1.0

|

|

|

|

|||

|

Compressed air tank(㎡)

|

1.0

|

1.5

|

2.0

|

2.0

|

2.5

|

|||

|

Cold water tank(㎡)

|

5.0

|

6.0

|

10.0

|

15.0

|

15.0

|

|||

|

Boiler exhaust volume and pressure(T/h/Mpa)

|

0.6/0.6

|

1.0/0.6

|

|

|

|

|||

Recommend Products

Product Details

Stainless Steel Material

The equipment is made of stainless steel ,which is not easy to wear and oxidize. It is beautiful and easy to clean.

Strong Sealing

The pot cover is sealed with inflatable silicone rubble ring,reliable sealing and long service life.

Large Heating Area

It has the advantages of high thermal efficiency, uniform heating, short boiling time and easy control of heating temperature.

Compact Structure

Concise, space-saving design New design supporting structure.transfer the preheating tank weight to the ground instead of working on the sterilization chamber, Avoid door deformation caused by over weighting.

Reduce Noise And Vibration

Water vapor mixer, reduce noise and vibration, better heating.

Saving Energy

Preheating water tank, recycling using hot water, Saving energy.

Support Customization

The machine can be customized, reasonable design and wide use.

Features of Water Immersion RETORT

1 Temperature up directly and down indirectly

2 Sterilizing water can be recycled

3 Cooling water can be recycled

4 PLC control system , full automatic, input instruct with touch screen

5 Heating and cooling step by step

6 Sterilizing technology can be stored automatic

7 Sterilizing temperature and time can record

8 Manual control system and automatic control system are separated,both of them can be operate alone

9 Alarming automatic when temperature ,pressure and water level is abnormal

10 Electronic revise temperature offset

11 Auto temperature adjustable electrical

12 Electronic protect automatic when temperature is too high

13 Electric and machinery over-pressure protection

14 Heat distribution evenly, temperature keep within 0.5 degree C

15 Electric and machinery safety interlock

Product packaging

Why Choose Us

FAQ

Q1: Are you factories? What do you mainly do?

A1:

Yes, Xinlongjia is a food machinery processing and production enterprise integrating scientific research, production and sales. Our main products are popcorn production line,industrial pot,horizontal food sterilizer,marinating machine meat,saline injection machine,meat processing machinery,sausage processing line,chicken nuggets production line,ball production line and so on.

Q2: Where is your factory? Which port is close to?

A2:

Our factory is in Zhucheng, Shandong, China, and is very close to Qingdao Port.

Q3: Can you provide on-site installation?

A3:

Yes, We provide, please contact our business manager for specific details.

Q4:What's your company after-sales service?

A4:

Our machine will be checked three times before shipment to ensure that the machine itself has no problems. If the machine has some problems under incorrect operation:

1. improper operation problem, we will solve all the usage problems by video call.

2.machine parts problem, we will send you accessories to ensure the normal use of the machine.

3.In addition, our engineers go abroad every year to help customers solve problems they cannot solve. Give customers the best quality machine, the best service,Is the standard of our company.

Q5:Any warranty?

A5:

One year warranty. Frankly speaking, The quality of our machines is very stable. The machine will be tested three times before leaving the factory to ensure that the machine is in the best condition when it arrives at your address. Some minor problems of the machine are usually caused by incorrect operation by novices, so we provide a full set of English instruction videos and common problem solving videos, To help users better understand it. On the other hand, we put a set of spare parts in the toolbox of the machine in advance. During your use, if you need any spare parts, we can send it to you via UPS, and it only takes 5-7 days to arrive at your door. During use, if you have any questions, we can make a video call at any time.

Hot Searches