- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

kingmachine

-

Dimension(L*W*H):

-

2450*1800*2350

-

Weight:

-

3500kg

-

Certification:

-

CE, ISO,SGS

-

Key words:

-

Beer Making Machine

-

market:

-

Glass bottle filling machine global

-

material:

-

SUS304/SUS316

-

capacity:

-

4000-16000

-

processing:

-

Filling Plant

-

Product Name:

-

Glass Bottle Beer Making Machine

Quick Details

-

Packaging Material:

-

Glass, Metal, Plastic

-

Voltage:

-

3 phase

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

kingmachine

-

Dimension(L*W*H):

-

2450*1800*2350

-

Weight:

-

3500kg

-

Certification:

-

CE, ISO,SGS

-

Key words:

-

Beer Making Machine

-

market:

-

Glass bottle filling machine global

-

material:

-

SUS304/SUS316

-

capacity:

-

4000-16000

-

processing:

-

Filling Plant

-

Product Name:

-

Glass Bottle Beer Making Machine

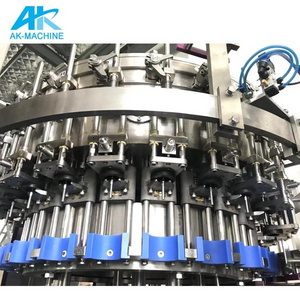

Glass Bottle Beer Making Machine

This BGF Wash-filling-capping 3-in-1unit: Beverage Machinery is used to produce beer filling machine. The BGF Wash-filling-capping 3-in-1unit: beer Machinery can finish all the process such as press bottle, filling and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

1.Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan\'s Mitsubishi, France Schneider, Siemens.

|

Product Name |

Beer or Wine Glass Bottle Washing Filling Capping 3-in-1 Machine |

|

Item Type |

Wine/Beer filling machine |

|

Place of Origin |

Jiangsu, China (Mainland) |

|

Material |

SUS 304 or SUS316 |

|

Voltage |

220V/380V/440V or customized |

|

Power |

4.4~10KW |

|

Dimension |

Customized |

|

Weight |

According to different model |

|

Capacity |

300-8000bph |

|

After-sales Service Provided |

Engineers available to service machinery overseas |

|

Bottle |

Glass/Plastic Bottle |

|

Bottle Size |

350ml-1500ml |

|

Suitable bottle |

Plastic, glass |

|

Application |

Beverage filling |

|

Certification |

CE SGS ISO |

|

Warranty |

1 year |

The beer filling machine used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic.

Installation service

When you finish the Preparation conditions,our fast and professional aftersales service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

The sample service

1.We can send you the video of the running machine.

2.You are welcome to come to visit our factory,and see the machine running.

Customized service

1.We can design the machines according your requirements(materil,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions,our fast and professional aftersales service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

3. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty

5.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

6 .24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

7 .12 Months guarantee and life-long technical support.

8.Your business relationship with us will be confidential to any third party.

9. Good after-sale service offered, please get back to us if you got any questions.

Quality Control

We have the single quality department,that make sure the material of the raw materials is good,and ensure the machine running smoothly.

|

Model |

Washing heads |

Filling heads |

Capping heads |

Capacity 500ml(bph) |

Bottle size (L) |

|

BGF6-6-1 |

6 |

6 |

1 |

300-500 bph |

0.35-1.5L |

|

BGF18-18-6 |

18 |

18 |

6 |

1500 bph |

0.35-1.5L |

|

BGF24-24-8 |

24 |

24 |

8 |

2500-3500bph |

0.35-1.5L |

|

BGF32-32-10 |

32 |

32 |

10 |

4000-6000bph |

0.35-1.5L |

|

BGF40-40-10 |

40 |

40 |

10 |

8000bph |

0.35-1.5L |

|

You can also customize the size you need |

|||||