- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Overseas service center available

-

Type:

-

Semi-automatic

-

Certification:

-

Main electric components are CE certificated.

-

Color:

-

RAL9010 or as per customer requirement

-

Name:

-

coil insertion machine

-

Used for:

-

coil inserter parts

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

NIDE

-

Weight (KG):

-

850

-

After-sales Service Provided:

-

Overseas service center available

-

Type:

-

Semi-automatic

-

Certification:

-

Main electric components are CE certificated.

-

Color:

-

RAL9010 or as per customer requirement

-

Name:

-

coil insertion machine

-

Used for:

-

coil inserter parts

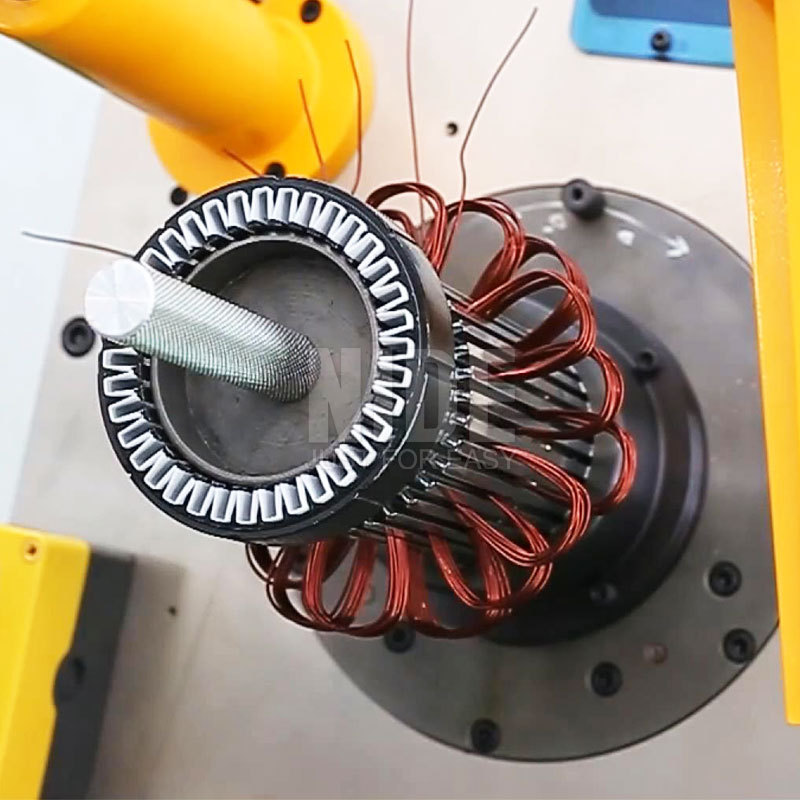

Automatic coil insertion machine

(1) Main technicaldata

Stator stack length: 10--150mm

Stator OD: Max. 160mm

Stator ID: 30~110mm

Tooling traveling distance: Max.60mm

Suitable wire material: copper/ aluminium wire

Slot number: 8~48slots

Max. slot filling rate: 80%

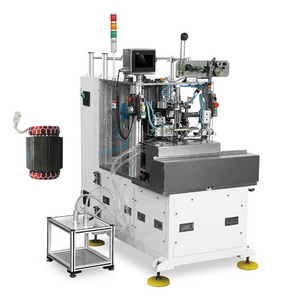

Power: 380V/50/60HZ 3Kw

Machine weight: about 850kg

Machine dimension: L1850*W650*1700mm

(2) Application

This stator coil insertion machine is suitable for air conditioner motor, washing machine motor, compression motor, fan motor, generator motor and pump motor.

(3) Machine mainfunction and characteristic

The coil insertion machine insert coil and wedge simultaneously, coil insertion is controlled by servo motor system, and wedge insertion by variable frequency motor.

It is controlled by HMI, and machine can diagnose breakdown automatically.

This machine is suitable for Polyester Film wedge roll material with fixed thickness and fixed width (width and thickness dimension is provided by customer)

The wedge feeding is by stepping motor,feeding length, cutting, forming, inserting slot number could be set.

Both copper wire and aluminium wire are applicable.

Production capacity ≤25s/set (exclude theman-hours for auxiliary work)

Primary qualification rate for copper wire≥98.5%, after rework, the rate ≥99.5%

Both wedging system and feeding system have pre-decelerating function.

This machine has alarm for material rubout.

Wire pushing height and stop time can beset in the HIM interface.

This machine has fixed foot and removable wheel.

Wedge should not be damaged, no burr in the surface, no movement or slide.

Slot paper should not be damaged, nomovement or slide. Copper wire should not be pull away from the paper.

The stator should not be deformation or stator lamination should not be upward.

Motor stator manufacturing production assembly line including paper inserting machine, coil winding machine, coil winding inserting machine, lacing machine, forming machine and testing machine.NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

With good service, unique philosophy, professional team and reliable quality, we win the worldwide customers' confidence gradually. We directly and indirectly supply our products to more than 50 countries. Among the customers, many of them are the world-renown companies.

| Customerized service | 1. Customized product design and manufacturing |

| 2. Customized tranning | |

| 3.Technical suggestions | |

| After-sales service | 1. Warranty Period: 12 month usually |

| 2. Overseas service center available | |

| 3. Engineers available to service overseas |

Established in 2010, Nide is a company devoted in the field of electric motors manufacturing, providing one-stop service for its customers.

Nide has three main business divisions.

The first division is to provide

different kinds of motor manufacturing machinery,

it is our Main business, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.

The second division is to supply the full range of

motor components

such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.

The third division is to provide

technical support and consulting, project support and turn-key service

for some motor manufacturing.

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.