- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MINGGONG

-

Weight:

-

17500 KG

-

Product Name:

-

Jaw Crusher Machine

-

Installation:

-

Engineer Guide

-

Applicaton:

-

Mining Quarry

-

Spare parts supply:

-

Lifelong Time

-

After sale Service:

-

Engineer Available

-

Factory Visit:

-

Welcomed Warmly

Quick Details

-

Application:

-

Stone Crusher

-

Capacity(t/h):

-

30-1250TPH

-

Place of Origin:

-

China

-

Brand Name:

-

MINGGONG

-

Weight:

-

17500 KG

-

Product Name:

-

Jaw Crusher Machine

-

Installation:

-

Engineer Guide

-

Applicaton:

-

Mining Quarry

-

Spare parts supply:

-

Lifelong Time

-

After sale Service:

-

Engineer Available

-

Factory Visit:

-

Welcomed Warmly

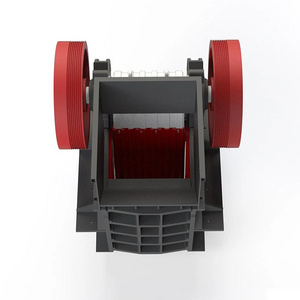

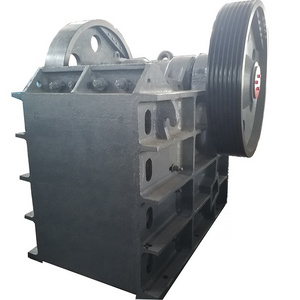

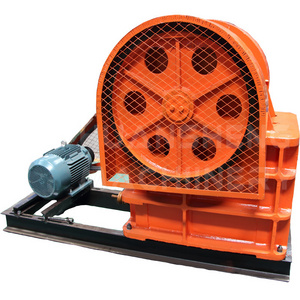

Product Showcase

1.PE Jaw Crusher

PE Jaw Crusher, including coarse crusher and fine crusher, is widely applied in the road building construction, in the future for the mines, with the characteristics of large ratio of reduction, uniform size, simple structure, reliable working, easy maintenance, and low operating cost. It has not more than 320Mpa of the compression strength and 125mm~1020mm of the feeding size, and is the preferred equipment for primary and secondary crushing. Shanghai minggong jaw crusher absorbs the advantages of the similar products at home and abroad, and is developed into the crushing equipment with high efficiency and energy saving. As the main products of sandstone series, all the models of jaw crushers take the lead on terms of design, production, and after-sales service. PE series jaw crusher is widely applied in the mines, smelting, building materials, highway, railway, water conservancy and chemicals etc.

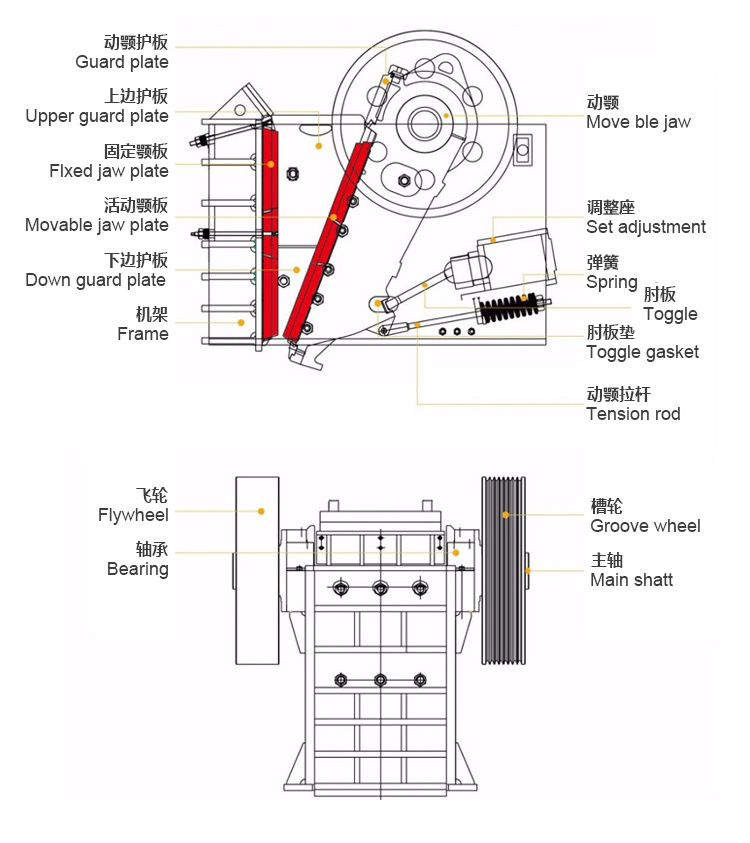

2.Working principle of Stone Jaw Crusher

By using motor as its power, the eccentric shaft is driven by the belt and belt wheel to make the movable jaw move up and down. When the movable jar ascends, the angle between the toggle plate and it becomes larger, push it toward the fixed jaw plate, reaching the purpose of crushing the materials. When the movable jaw descends, the angle becomes smaller, in the action of draw bar and spring, depart from the fixed jaw plate and discharge the materials, when the pressure rises to the strength beyond which the materials can bear, the crushing happens. Otherwise, when the fixed jaw swings in the opposite direction departing from the fixed jaw, the materials move downward by the self weight. Every periodical movement of the movable jaw will make the crushing effect on the materials, and send them a distance downward. The crushed materials will be discharged through the discharging opening after several periods.

3.Composition of Jaw Crusher

The Jaw Crusher is composed of rack, supporting device, operating mechanism(fixed jaw plate, movable jaw plate), transmission mechanism(eccentric rod, thrust plate, fly wheels, eccentric shaft), safety device, adjusting device(Wedge block adjusting device and gaskets adjusting device), toggle plate, toggle plate backseat, screw, returning springs etc, in which the toggle plate plays a role of safety.

Schematic diagram

1.Features of Stone Jaw Crusher crusher

1). Deep crushing cavity without dead zone, improve the feeding capacity and output.

2).The gaskets adjusting device of discharging opening, reliable and convenient, with large adjusting range, increases the flexibility of the equipment.it can meet different customers’ requirement

3).Adjustable for easy wear parts

4).over-loading protection

5).simple structure and easy to operate

6).Lubricate system is safe and reliable, easy to change the spare parts;

7).Less costly and Easy to install

8).Wide range of choices

9).wearable parts made of high manganese steel

10).High ratio of crushing, homogeneous final product size;

11).energy saving 15%~30% for one machine, more than doubled for the system

12).Little noise and dust.

2.The advantages of our Stone Crusher

1). superior quality

2). reasonable price

3).one year guarantee

4). our engineer guiding for installation on site for free

5).our after-sales service team act immediately on receiving your reports

6). providing high quality spare parts with low prices in order to appreciate your trust on our factory

3.Jaw crusher operating cycle

In the process of large stones crushing into the small ones, the first step of crusher is called primary crusher. The jaw crusher is of the most common use and hardest one. The materials are fed into the crushing cavity from the top, forced to the cavity wall by the jaw tooth driven by the eccentric shaft throughout the frame, and crushed into smaller stones. The eccentric movement is normally made by the fly wheels fixed on the both ends of the shaft. The roller bearings in support of the flywheels and eccentricity must bear the large impact load, Abrasive sewage, and high temperature. In spite of that, the jaw crusher can work reliably, which is the key link for guaranteeing the production efficiency.

Application of Stone Jaw Crusher

This series of jaw crusher manufacturers is mainly used for rough and moderate broken operations of various ore materials those compressive strength are not more than 320 MPa. This crusher has features of high broken ratio, uniform product size, simple structure, reliable operation, convenient maintenance, low operating costs etc, which is widely used in mining, smelting, building, roads, railways, water conservancy and chemical industry.

1.dolomite

2.platinum

3.Gangue

4.Calcite

1.Calcium ore

2.Manganese ore

3.Cobalt ore

4.granite

Technical Parameters

|

model

|

feeding

|

maximum

|

adjustable

|

Handling

|

eccentric shaft

|

Motor

|

total weight

|

Overall dimensions

|

|

|

size

|

feeding

|

range

|

ability

|

rotate speed

|

power

|

(t)

|

(L*W*H)(mm)

|

|

|

(mm)

|

size(mm)

|

(mm)

|

(t/h)

|

(r/min)

|

(kw)

|

|

|

|

PE-150×250

|

150×250

|

125

|

10-40

|

1-3

|

250

|

5.5

|

0.8

|

720×660

×850

|

|

PE-200×300

|

200×300

|

180

|

15-50

|

2-6

|

260

|

7.5

|

1.2

|

910×750

×990

|

|

PE-200×350

|

200×350

|

180

|

18-70

|

3-10

|

260

|

11

|

1.5

|

1000×870

×990

|

|

PE-250×400

|

250×400

|

210

|

20-60

|

5-20

|

300

|

15

|

2.8

|

1300×1090

×1270

|

|

PE-400×600

|

400×600

|

340

|

40-100

|

16-60

|

275

|

30

|

7

|

1730×1730

×1630

|

|

PE-500×750

|

500×750

|

425

|

50-100

|

40-110

|

275

|

55

|

12

|

1980×2080

×1870

|

|

PE-600×750

|

600×750

|

500

|

150-200

|

80-240

|

275

|

55

|

15.8

|

2070×2000

×1920

|

|

PE-600×900

|

600×900

|

500

|

65-160

|

50-180

|

250

|

55

|

17

|

2190×2206

×2300

|

|

PE-750×1060

|

750×1060

|

630

|

80-140

|

110-320

|

250

|

90-110

|

29

|

2660×2430

×2800

|

|

PE-800×1060

|

800×1060

|

640

|

160-220

|

130-330

|

250

|

110

|

29.8

|

2710×2430

×2800

|

|

PE-830×1060

|

830×1060

|

650

|

160-220

|

150-336

|

250

|

110

|

30.7

|

2740×2430

×2800

|

|

PE-870×1060

|

870×1060

|

660

|

200-260

|

190-336

|

250

|

110

|

31.5

|

2810×2430

×2800

|

|

PE-900×1060

|

900×1060

|

685

|

230-290

|

230-390

|

250

|

110

|

33

|

2870×2420

×2940

|

|

PE-900×1200

|

900×1200

|

750

|

95-165

|

220-450

|

200

|

110

|

52

|

3380×2870

×3330

|

|

PE-1000×1200

|

1000×1200

|

850

|

195-265

|

315-500

|

200

|

110

|

55

|

3480×2876

×3330

|

|

PE-1200×1500

|

1200×1500

|

1020

|

150-300

|

400-800

|

180

|

160

|

100.9

|

4200×3300

×3500

|

|

PEX-150×750

|

150×750

|

120

|

18-48

|

8-25

|

320

|

15

|

3.8

|

1200×1530

×1060

|

|

PEX-250×750

|

250×750

|

210

|

25-60

|

13-35

|

330

|

30

|

5.5

|

1380×1750

×1540

|

|

PEX-250×1000

|

250×1000

|

210

|

25-60

|

16-52

|

330

|

30

|

7

|

1560×1950

×1390

|

|

PEX-250×1200

|

250×1200

|

210

|

25-60

|

20-61

|

330

|

37

|

9.7

|

2140×1660

×1500

|

|

PEX-300×1300

|

300×1300

|

250

|

20-90

|

16-105

|

300

|

55

|

15.6

|

2720×1950

×1600

|

Product Details

Our Project

More Products

Packaging & Shipping

Packaging Details:

We will make different packaging according to different machine sizes .standard international export packing, container, wooden box.

Delivery Time:

We will customize according to the actual needs of customers. Senior designers start to design the plan. After receiving the deposit, we will complete the delivery within 20 to 30 working days.

Our factory is capable of shipping large machine even more than 100 tons

Hot Searches