- Product Details

- {{item.text}}

Quick Details

-

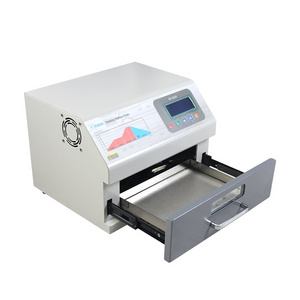

Brand Name:

-

SHENGDIAN

-

Model Number:

-

SD-800XL

-

Product name:

-

reflow soldering machine

-

Name:

-

SMT Production Line

-

Application:

-

SMT PCB Assembly Production Line

-

Usage:

-

SMD LED SMT

-

Power Supply:

-

3 phase 5 wire 380V

-

Type:

-

SMT Machine Parts

-

Dimension:

-

5000 *1300*1550mm

-

Weight:

-

2000KG

-

Transport direction:

-

L to R or R to L (optional)

Quick Details

-

Weight (KG):

-

1000

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

GuangDong,china(mainland)

-

Brand Name:

-

SHENGDIAN

-

Model Number:

-

SD-800XL

-

Product name:

-

reflow soldering machine

-

Name:

-

SMT Production Line

-

Application:

-

SMT PCB Assembly Production Line

-

Usage:

-

SMD LED SMT

-

Power Supply:

-

3 phase 5 wire 380V

-

Type:

-

SMT Machine Parts

-

Dimension:

-

5000 *1300*1550mm

-

Weight:

-

2000KG

-

Transport direction:

-

L to R or R to L (optional)

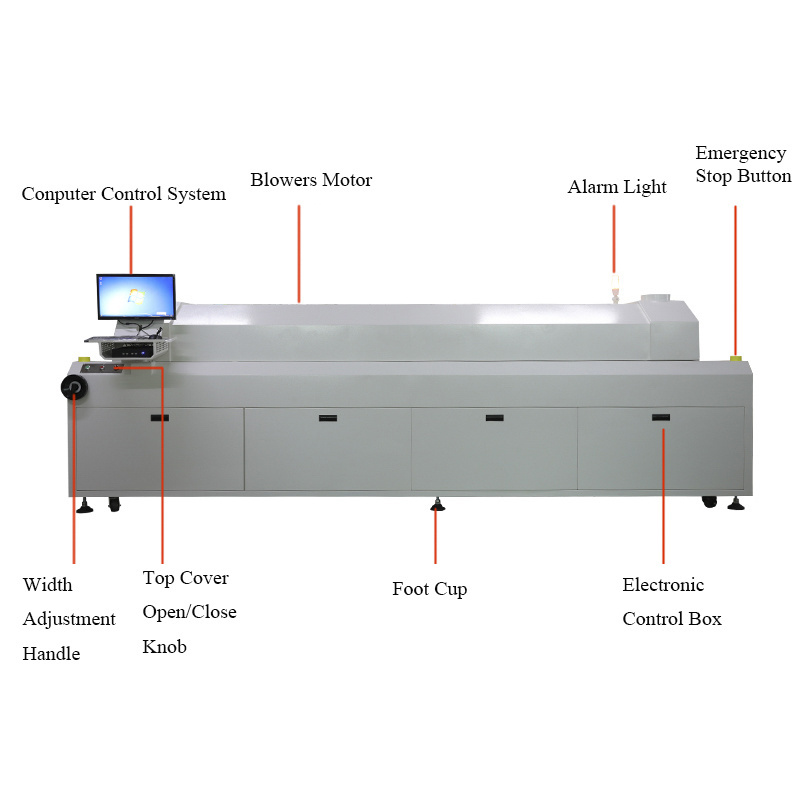

800XL full hot air circulation lead-free reflow soldering technical parameters

|

Transport mechanism |

||

|

1 |

Conveyor belt width |

5 50 mm |

|

2 |

Transmission method |

Chain/net belt transmission |

|

3 |

Conveying direction |

Left → right, right → left (optional) |

|

4 |

Transmission chain surface height |

900 mm ±20 |

|

5 |

Transportation speed |

0~2200 mm/min |

|

6 |

rail |

Special anti-twist aluminum alloy profiles |

|

7

|

Chain expansion |

Less than 2.5mm |

|

8 |

Chain lubrication |

Automatic refueling device |

|

9 |

Chain tensioning device |

Chain tensioning automatically |

|

cooling system |

||

|

1 |

Two cooling zones |

AC380V direct-shaft motor turbocharger |

|

2 |

Rosin smoke treatment |

Preheating zone and constant temperature zone + special pipelines before and after the furnace |

|

|

cooling method |

Extended turbocharged cooling zone: 2 cooling zones + 1 separate cooling zone |

|

3 |

It can fully meet the cooling rate of lead-free soldering at 4-8 °C/S. |

|

|

Control System |

||

|

No. |

Scope of application |

||

|

1 |

Suitable for solder paste type |

Lead-free solder, ordinary solder, red glue |

|

|

2 |

Processing the maximum substrate size (MM) |

MAX 55 0(mm) |

|

|

3 |

Applicable component type |

0805, 0603, 0402. 0201, 01005 small components CSP, BGA, etc. single-sided / double-panel |

|

|

Dimensions |

|||

|

1 |

Dimensions L*W*H( MM ) |

5310 *1 56 0*15 6 0 mm |

|

|

2 |

machine weight |

2 0 00KG |

|

|

3 |

Temperature zone |

Upper 8 hot air, lower 8 hot air, 16 temperature control, 3 dedicated cooling zones |

|

|

temperature control |

|||

|

1 |

Temperature control method |

Each temperature zone is independently controlled by temperature module PID+pulse+SSR |

|

|

2 |

Temperature zone control accuracy |

±1℃ |

|

|

4 |

Temperature control range |

Room temperature~350 0 C |

|

|

5 |

Heating time (cold start) |

15-30 minutes or so |

|

|

6 |

Temperature stabilization time |

Within 2 minutes |

|

|

Furnace structure |

|||

|

1 |

Wind mode |

Using the world's leading hot air circulation technology, the use of hot air circulation through turbocharging makes the hot air stable; the thermal efficiency recycling rate is high, that is, energy saving and stable. When the PCB passes a lot, the temperature curve on each PCB passes through only one board. The temperature profile is always consistent, and the heating repeatability is extremely high, which is very suitable for the small process space in the lead-free process. (Improved by imported furnace technology) |

|

|

2 |

Internal structure |

The turbine double outlet is used to increase the wind speed pressure, so that the wind speed is stable, the temperature is stable, and the welding effect is better.; |

|