- Product Details

- {{item.text}}

Quick Details

-

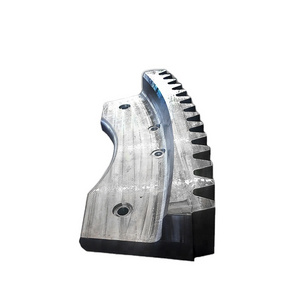

Product Name:

-

Large Ring Gear

-

Process:

-

Milling,hobbing

-

OEM Service:

-

YES

-

Test:

-

Raw material inspection, UT, MT,inspection, size inspection

-

number of teeth:

-

176

-

Application:

-

Rotary Cement Kiln & Rotary Kilns & Rotary Dryer

-

Heat treatment:

-

Quenching and tempering

-

Certificate:

-

ISO9001

-

Weight:

-

Max 50T per piece

Quick Details

-

Weight (KG):

-

50

-

Place of Origin:

-

China

-

Brand Name:

-

Ruding

-

Product Name:

-

Large Ring Gear

-

Process:

-

Milling,hobbing

-

OEM Service:

-

YES

-

Test:

-

Raw material inspection, UT, MT,inspection, size inspection

-

number of teeth:

-

176

-

Application:

-

Rotary Cement Kiln & Rotary Kilns & Rotary Dryer

-

Heat treatment:

-

Quenching and tempering

-

Certificate:

-

ISO9001

-

Weight:

-

Max 50T per piece

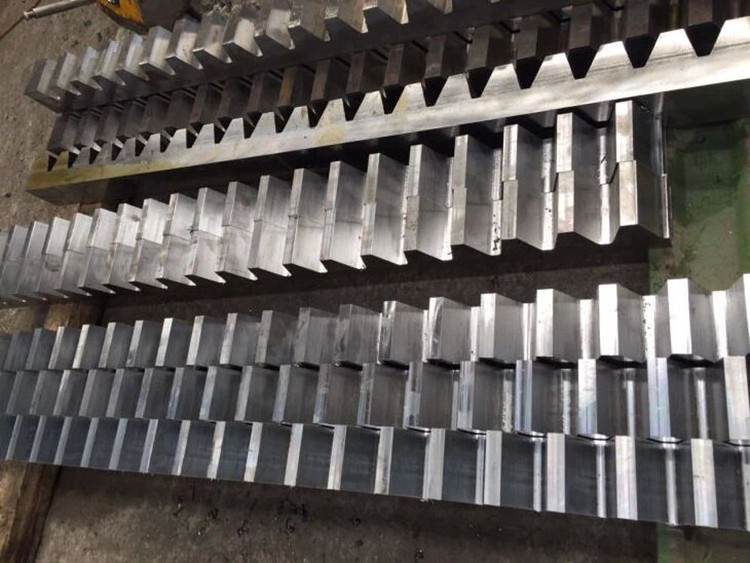

The gear rack is a special gear with teeth distributed on the strip body. The racks are also divided into straight racks and helical racks, which are paired with spur gears and helical gears, respectively; the tooth profile of racks is straight rather than involute (it is flat for tooth surfaces) .

Ruding Steel can supply large size gear rack, mining rack,reduction box gear rack Non-standard rack, Marine rack, Helical rack, Round rack, Port machine rack, Heavy Duty Rack, Curved rack, Construction lift rack and Ny. etc.

Specifications:

|

Material |

Carbon steel,Alloy steel |

|

Structure |

Forging,casting |

|

Type of gear |

Herringbone gear |

|

Heat treatment |

Quenching and tempering |

|

Process |

Forging, rough machining, QT, finish machining |

|

Main equipments |

Hobbing,CNC machine |

|

Module |

Up to 200 |

|

Precision of gear |

Grinding ISO Grade 5-7 & Hobbing ISO Grade 8-9 |

|

Inspection |

Raw material inspection, UT,physical property test,dimension inspect |

Manufacturing process:

Rraw matrial -- Forging testing-- Turning -- Drilling -- Heat Treatment -- Milling-- Grinding -- Shaping and hobbing Process -- Packing -- Shipping

1. OEM and customized service.

2. Full machining, primer coating, surface treatment.

3. Complete material testing process.

4. Quality control

Please contact us for more information and quotations.