- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

2000 mm

-

Travel (Y Axis)(mm):

-

4000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

9KW

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

suntec

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

4000*2250*1800mm

-

Weight (KG):

-

3000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

working area:

-

2000*4000

-

Drill center:

-

FAM5+4

-

Control system:

-

Syntec 6MB/TPA

-

Transmission:

-

XY-axis:rack z ballscrew

-

Driver:

-

Japan yaskawa

-

invertor:

-

Delta

-

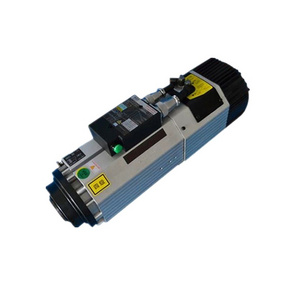

spindle:

-

9KW /6kw HQD

-

working table:

-

vacuum table

-

Certification:

-

CE ISO

Quick Details

-

Working Table Size(mm):

-

2000×4000

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

1 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

2000 mm

-

Travel (Y Axis)(mm):

-

4000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

9KW

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

suntec

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

4000*2250*1800mm

-

Weight (KG):

-

3000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

working area:

-

2000*4000

-

Drill center:

-

FAM5+4

-

Control system:

-

Syntec 6MB/TPA

-

Transmission:

-

XY-axis:rack z ballscrew

-

Driver:

-

Japan yaskawa

-

invertor:

-

Delta

-

spindle:

-

9KW /6kw HQD

-

working table:

-

vacuum table

-

Certification:

-

CE ISO

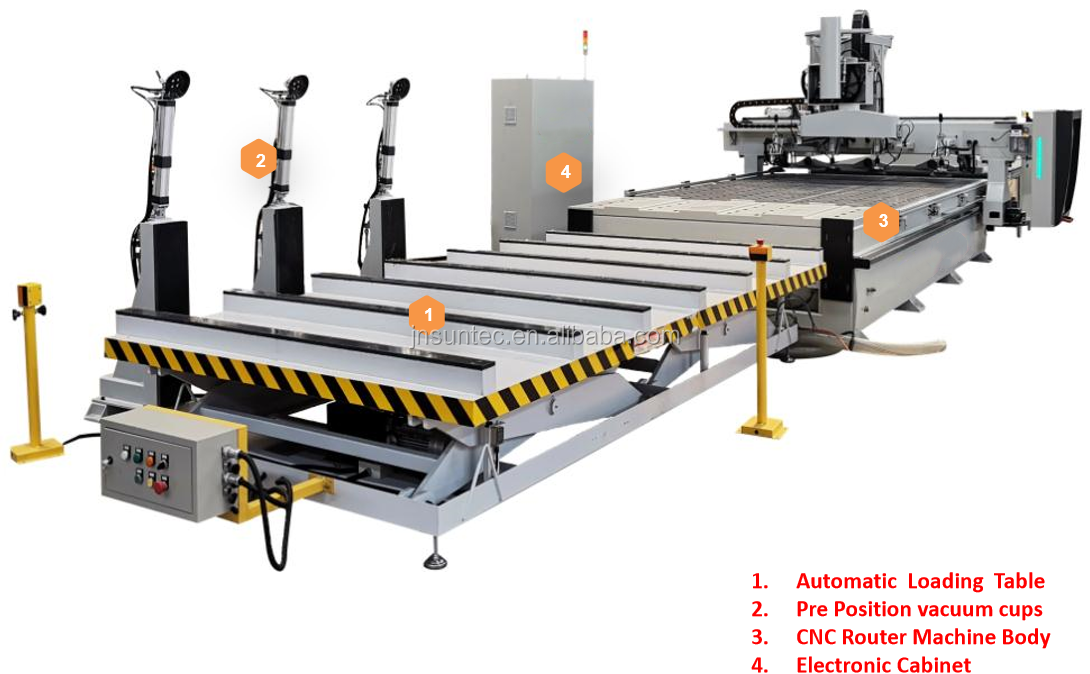

automatic loading unloading cnc nesting cnc woodworking cnc machine 9kw spindle ATC drilling 5+4 ST2040

https://www.facebook.com/profile.php?id=100007453230298

https://youtu.be/RwlRnGGfUXg

Application of china cnc milling machine

1)

Furniture industries:

cabinet doors, wooden doors, solid woods, plates, antique furniture, doors, windows, desks and chairs.

2)

Decoration industries:

screens, wave boards, large-size wall hangings, advertising boards and sign making.

3)

Arts & Crafts industries:

Engrave on artificial stones, woods, bamboos, marbles, organic boards, double-color boards and so on for achieveing effects of exquisite patterns and characters.

4)

Processing material:

engraving, milling and cutting processing for acrylic, PVC, density boards, artificial stones, organic glass, plastics and soft metal sheets such as copper and aluminum

Machine Feature

1) Automatic Loading & Unloading machine, be equipped with ATC, 9V6H1S drilling bits, CN2008/Mechatrolink II/TPA/Italy. Be widely applied for processing closet, cabinet and so on.

2)

Appearance:

New design gantry cover, whole machine body cover.

3)

Pre-position Setting:

three vacuum cups to adjust the panel before loading.

4)

Back & Side Pusher

: Adjust the panel to the right position before processing it

5)

Vacuum Detector:

Automatically detect if the vacuum power is OK before processing

6)

Vacuum Release

: Release the vacuum and detect if there is still vacuum working on the panel, if not, then the automatic pusher can push the panel off the vacuum table.

7)

Conveyor

: Connect to the PLC system, can detect if there is another panel on the waiting table, if not ,then can push the panel to waiting table.

8)

Vacuum table:

Double PVC layer, 5 vacuum zones for different panel size.

9) Independent electric cabinet & control panel

|

Travailing size |

4000*2000*200mm |

|

Working size |

4000*2000*80mm |

|

Table size |

2440*1250m |

|

Loading and Unloading Speed |

15 m/min |

|

Transmission |

X/Y rack and pinion drive, Z ball screw drive |

|

Table structure |

Vacuum table |

|

Spindle power |

9.0 KW |

|

Spindle speed |

24000r/min |

|

Travailing speed |

80m/min |

|

Working speed |

25m/min |

|

Tool magazine |

Carousel |

|

Tool slots |

16 PCS |

|

Driving system |

YASKAWA |

|

Voltage |

AC380/3PH/50HZ |

|

Controller |

TPA/syntec |

Main Details

1)Machine body: Welded steel body and gantry

2)Working Area: 2100mm*3800mm*80mm(Feed in)

3)Spindle: HSD 12.0KW /Air Cooling/24000rpm

4) Drilling Head: HSD 9V6H1S/1.7KW

5) TBI D=25mm Ball Screw, HIWIN 30mm Linear Guide

6)German Herion Slanted Rack and pinion/2.0M,

7) YASKAWA Servo motor 1300W & Driver Mechatrolink II

8)Japan SHIMPO Reducer; Delta Inverter / 15KW

9) Controller: TPA CN2008 with PC&Monitor&Handbox, N°1 WSCM SW0.2.01; 10) Software: TPACAD+Nesting professional 11) Table: Double layer PVC Vacuum/ 4 zone/Solenoid valves

12)Vacuum Pump: 7.5KW/air cooling/320M3/H*2Pcs

13)Dust Hood: D=200mm, Boring hood: D=100mm

14) Automatic loading and unloading, 3 big pads for pre-align before loading , Back Pusher 3pcs ,Lateral pusher*4 pcs 15)ATC/Round style&16 pcs/ Clamps &Shank -HSK-F63, 1*Aluminum clamp for Aggregate 16) Automatic lubrication system 17)Europe gantry cover design and Solo movable PC cabinet

7 .Big heavy cover

Main parts

Pre-position: move the panel to adjust the panel position before loading the panel

Packing

Services & Guarantee:

1.Techbical supports and suggestions.

2.Professional instruction for the operation of the macine

3.12 month for the whole machine,provide a few extra consumable parts.

4.If necessary send technician to the scene to solve the problem asap.

5.24-hour technical support by email or calling.

Contact :

anna

skype anna886691

whatsapp 8615966606596

wechat anna88669

24 hours on line service