- Product Details

- {{item.text}}

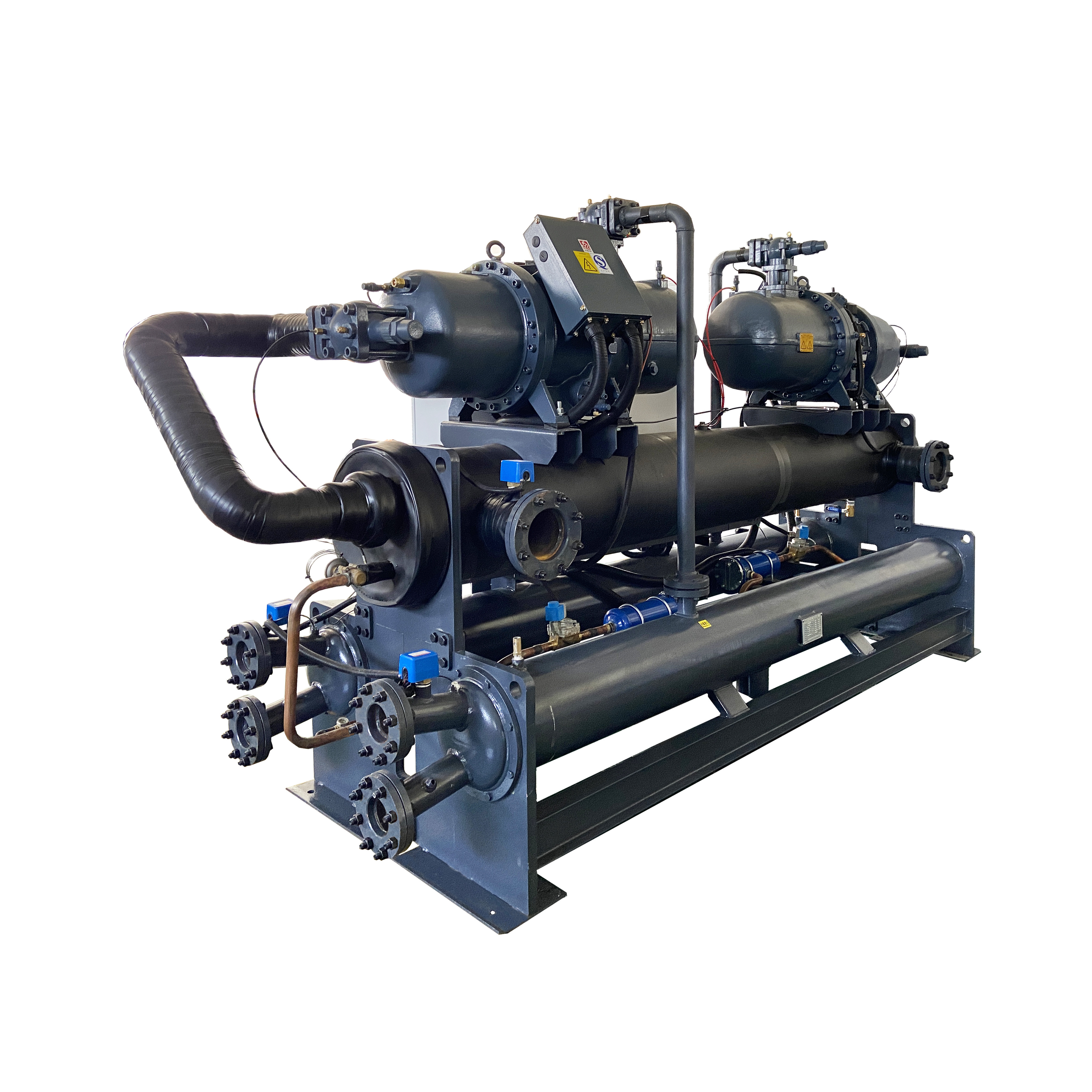

Quick Details

-

Voltage:

-

3PH~380/415V/460V~50HZ/60HZ

-

Dimension(L*W*H):

-

4500*1700*1800mm

-

Weight:

-

6200 KG

-

Compressor type:

-

Semi-hermetic screw type

-

Compressor Brand:

-

Bizter / Hanbell

-

Compressor stage:

-

25-50-75-100%

-

Start mode:

-

Y-delta or Soft starter

-

Refrigerant:

-

R407c/R134a/R407c/R404a

-

Evaporator:

-

Shell and tube

-

Condenser:

-

Shell and tube

-

Refrigeration circuit:

-

2

-

Inlet/outlet pipe fitting:

-

10"

-

Cooling tower:

-

Required

Quick Details

-

Condition:

-

NEW100%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MGREENBELT

-

Voltage:

-

3PH~380/415V/460V~50HZ/60HZ

-

Dimension(L*W*H):

-

4500*1700*1800mm

-

Weight:

-

6200 KG

-

Compressor type:

-

Semi-hermetic screw type

-

Compressor Brand:

-

Bizter / Hanbell

-

Compressor stage:

-

25-50-75-100%

-

Start mode:

-

Y-delta or Soft starter

-

Refrigerant:

-

R407c/R134a/R407c/R404a

-

Evaporator:

-

Shell and tube

-

Condenser:

-

Shell and tube

-

Refrigeration circuit:

-

2

-

Inlet/outlet pipe fitting:

-

10"

-

Cooling tower:

-

Required

Water Cooled Chiller Protection Systems:

1. Compressor protection: The compressor is the most crucial and expensive component in a chiller unit, so it is necessary to install compressor protection systems. For example, when there is a compressor fault such as high temperature, low oil pressure, or overload, the power is automatically cut off, and the user is notified via a display screen.

2. Water flow protection: In a water-cooled screw chiller, insufficient or excessive water flow can cause equipment sedimentation and abnormal operation risks, so a water flow protection detection system is usually set up. When water flow is detected to be too low or too high, it will automatically control and alert or shut down the machine to avoid the risk of repair or replacement of components due to waterway issues.

3. Temperature protection: To prevent exceeding the set temperature range and causing harm such as overheat or freezing equipment, the automation system can adjust the water flow or gas flow to achieve stable temperature effects.

4. Energy-saving protection: By using advanced energy control technology to perfect the automatic control system of the chiller, the operation of the chiller is monitored in real-time, and the refrigeration process is optimized and adjusted to save energy and reduce equipment failure rates.

The above protection systems ensure the safety and reliability of the water-cooled screw chiller equipment and maximize its energy

efficiency and lifespan.

water-cooled screw chiller with two compressors typically has the following features:

1. High efficiency and energy saving: It employs high-efficiency and reliable twin-screw compressors that offer stable and

efficient refrigeration, low noise, as well as safe and reliable operation. It can open or close one or multiple compressors

based on demand to achieve better energy efficiency and reduce power consumption.

2. High stability: It is equipped with a backup compressor, and if a compressor fault occurs, the backup compressor can be quickly switched to work, reducing production downtime and losses.

3. Convenient control and operation: The automatic monitoring and centralized management are achieved through a PLC control system, and it allows for smart operation by setting parameters via touch screens, remote terminals and other methods.

4. Easy maintenance: The advanced structural layout and refrigeration system design make cleaning and maintenance more convenient. Furthermore, the use of highly flexible components can lead to rapid replacement of parts in accordance with different customer requirements.

Two Quantity Screw Compressor

Advanced import brand Hanbell/Bitzer

Capacity energy control 3 or 4 or stepless

Loading and unloading automatically depends on production request

Simens PLC or Micocomputer LCD touch screen control

2 condenser , shell and tube type

1 evaporator , shell and tube type

Complete system for 150 tons water cooled chiller with 2 compressors

1- water cooled chiller

2- Cooling tower

3- Cooling pumps

4- Chilled water pumps

5- Water tank

|

Model

|

|

MG-450WD

|

MG-500WD

|

MG-550WD

|

MG-600WD

|

MG-620WD

|

|||||

|

|

USRT

|

128.8

|

138.2

|

161.5

|

171.7

|

176.3

|

|||||

|

Capacity

|

Kcal/h

|

389580

|

417960

|

488480

|

519440

|

533200

|

|||||

|

|

KW

|

453

|

486

|

568

|

604

|

620

|

|||||

|

Power

|

|

3PH-220V/380V415/440V/460V-50Hz/60Hz

|

|

|

|

|

|||||

|

|

Type

|

R22 / R407c/ R134a/ R410a

|

|

|

|

|

|||||

|

Refrigerant

|

Control

|

Thermostatic expansion valve

|

|

|

|

|

|||||

|

Comperssor

|

Type

|

Semi-Hermetic screw type

|

|

|

|

|

|||||

|

|

kw Power

|

107.9

|

109.6

|

124.2

|

132.2

|

135.2

|

|||||

|

|

Start

|

Y-△

|

|

|

|

|

|||||

|

|

Capacity

|

25-50-75-100(%) or 25-100(%)

|

|

|

|

|

|||||

|

|

Type

|

High efficiency copper tube shell and tube type

|

|

|

|

|

|||||

|

Evaporator

|

m³/h Flow

|

77.7

|

83.3

|

97.4

|

103.5

|

106.3

|

|||||

|

|

Inlet/Outlet

|

DN125

|

DN125

|

DN125

|

DN150

|

DN150

|

|||||

|

|

Type

|

High efficiency threaded copper tube shell and tube type

|

|

|

|

|

|||||

|

Condenser

|

m³/h Flow

|

105.8

|

112.3

|

130.5

|

138.8

|

142.4

|

|||||

|

|

Inlet/Outlet

|

DN125

|

DN125

|

DN125

|

DN150

|

DN80*2

|

|||||

|

Protection System

|

|

Compressor overheat protection, high/low pressure protection,phase missing/sequence protection, flow rate protection, anti-frozen

protection. |

|

|

|

|

|||||

|

Dimension

|

L

|

4000

|

4000

|

4000

|

4000

|

4000

|

|||||

|

|

W

|

900

|

1000

|

1000

|

1000

|

1400

|

|||||

|

|

H

|

1500

|

1800

|

1800

|

1800

|

1600

|

|||||

|

Weight

|

kg

|

1700

|

1900

|

2050

|

2150

|

2300

|

|||||

Product Application

MGREENBELT Industrial chiller is a good partner for the modernized industry , which feather as easy to operate with reasonable design, high quality and complete range of specifications.

Plastics

– injection molding, PET, blow molding, woven sack extrusion, sheet and profile extrusion, thermoforming, presses, etc

Automobile and Mechanical Engineering

– machine tool, induction hardening and heating, welding machines, rolling mills, presses, cutting, profiling, polishing, electric discharge machine, hydraulic oil cooling, heat treatment, component washing, component cooling, environmental test chambers, drive cooling, plasma spray, vacuum systems, etc.

Metal working

– Water jet cutting, power press, hydraulic oil cooling, laser cutting, aluminium extrusion, precious metal processing, etc.

Paper and related

– printing machine, labeling machine, cardboard making, plastic film machine, etc.

Others

– textile, semiconductor, air compressor, concrete batching, dynamometer, furnace, etc.

We will meet the acme of perfection to serve and provide more details , price ,catalog,drawing ,video for you !

Orders for ready-made or custom-made chillers are welcome!

If you have any questions please don't hesitated to contact with us:

Libra Zhang

WhatsApp, Wechat: +86-17686681007

Skype : libra5813

Mobile: 008617686681007

Email: libra(at)mgreenbelt.com