- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

25

-

Voltage:

-

1-phase 220V 50Hz or customized

-

Current:

-

34A

-

Rated Capacity:

-

15kVA

-

Rated Duty Cycle:

-

24 hours

-

Dimensions:

-

535*245*550

-

Use:

-

brazing

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

portable high frequency induction brazing equipment

-

Application:

-

Brazing

-

Feature:

-

Energy Saving

-

Advantage:

-

High Welding Speed

-

Package:

-

Wooden Box

-

Keyword:

-

portable brazing machine

-

Heating:

-

Induction Heating

-

Key words:

-

high frequency brazing machine

Quick Details

-

Core Components:

-

PCB, Capacitor

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Lihua

-

Weight (KG):

-

25

-

Voltage:

-

1-phase 220V 50Hz or customized

-

Current:

-

34A

-

Rated Capacity:

-

15kVA

-

Rated Duty Cycle:

-

24 hours

-

Dimensions:

-

535*245*550

-

Use:

-

brazing

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

portable high frequency induction brazing equipment

-

Application:

-

Brazing

-

Feature:

-

Energy Saving

-

Advantage:

-

High Welding Speed

-

Package:

-

Wooden Box

-

Keyword:

-

portable brazing machine

-

Heating:

-

Induction Heating

-

Key words:

-

high frequency brazing machine

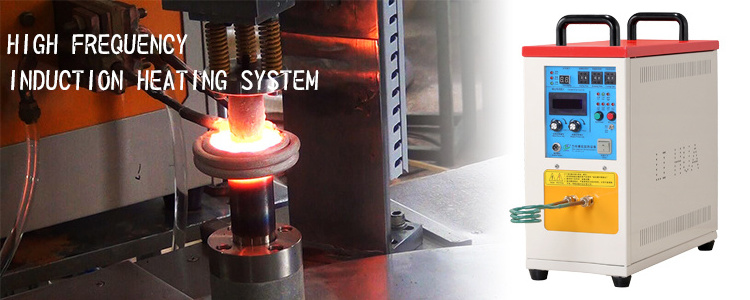

Product Description

Portable high frequency induction brazing machine

■ Adopted with MOSFET, IGBT power device and variable frequency control, LIHUA high frequency induction heaters enjoy high efficiency, energy saving and larger output power.

■ With constant current and constant power control function, the products can realize extremely optimized metal heating process,thus achieving high efficient, quick heating and greatly give play to the superiority of products.

■ Saving double electricity more than traditional high frequency induction heating device under the same conditions.

■ With 100% load design, it can work 24 hours constantly without a break. It can be equipped with infrared temperature measuring device to realize automatic control, promote heating quality and simplify artificial operation.

■ With three functional setting including heating-heat retaining-cooling, it can achieve required heating and incubation process to make itself suitable for repetitive and mass heating work.

■ The machine can display various states such as over current, over voltage, lacking of water, lacking of phase and light loading, thus providing higher reliability and durability.

Details Images

Front Side

Back Side

Germany IGBT

Circuit Board

Product Paramenters

|

High Frequency Induction Heating System

|

|

|

|

|

|

|||||

|

Model

|

LH-15A

|

LH-15AB

|

LH-25A

|

LH-25AB

|

LH-30AB

|

|||||

|

Input voltage

|

220V

|

220V

|

380V

|

380V

|

380V

|

|||||

|

Output power

|

15kW

|

15kW

|

25kW

|

25kW

|

30kW

|

|||||

|

Frequency

|

30-100KHz

|

30-100KHz

|

30-80KHz

|

30-80KHz

|

30-80KHz

|

|||||

|

Output current

|

200-600A

|

200-600A

|

200-1200A

|

200-1200A

|

400-1500A

|

|||||

|

Timing

|

1-99s

|

1-99s

|

1-99s

|

1-99s

|

1-99s

|

|||||

|

Cooling water

|

0.06-0.12Mpa

7.5L/min

|

0.06-0.12Mpa

7.5L/min

|

0.06-0.12Mpa

7.5L/min

|

0.08-0.12Mpa

7.5L/min

|

0.08-0.16Mpa

7.5L/min

|

|||||

|

Alarm tempreture

|

40°C

|

40°C

|

40°C

|

40°C

|

40°C

|

|||||

|

Generator weight

|

25kg

|

10kg

|

30kg

|

18.5kg

|

35kg

|

|||||

|

Transformer weight

|

/

|

15kg

|

/

|

15kg

|

10kg

|

|||||

|

Generator size (mm)

|

535*245*550

|

505*235*520

|

535*245*550

|

560*235*520

|

595*275*580

|

|||||

|

Transformer size (mm)

|

/

|

340*235*405

|

/

|

425*235*420

|

485*275*440

|

|||||

|

Model

|

LH-35AB

|

LH-40AB

|

LH-60AB

|

LH-80AB

|

|

Input voltage

|

380V

|

380V

|

380V

|

380V

|

|

Output power

|

35kW

|

40kW

|

60kW

|

80kW

|

|

Frequency

|

30-80KHz

|

30-80KHz

|

30-80KHz

|

30-80KHz

|

|

Output current

|

400-1600A

|

400-1800A

|

400-2400A

|

400-3200A

|

|

Timing

|

1-99s

|

1-99s

|

1-99s

|

1-99s

|

|

Cooling water

|

0.08-0.16Mpa

7.6L/min

|

0.08-0.16Mpa

7.6L/min

|

0.08-0.16Mpa

7.6L/min

|

0.08-0.16Mpa

9L/min

|

|

Alarm tempreture

|

40°C

|

40°C

|

40°C

|

40°C

|

|

Generator weight

|

35kg

|

35kg

|

37kg

|

54kg

|

|

Transformer weight

|

10kg

|

10kg

|

36kg

|

47kg

|

|

Generator size (mm)

|

595*275*580

|

595*275*580

|

650*320*590

|

745*345*600

|

|

Transformer size (mm)

|

485*275*450

|

485*275*450

|

485*275*450

|

790*425*580

|

Application

Recommend Products

Production Process

Hot Searches