- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.45-0.55mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

zhongtuo

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6800mm*800mm*1200mm

-

Weight:

-

4000 kg

-

Warranty:

-

one year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material of axis:

-

45#steel with chrome treatment

-

Raw Material type:

-

color steel sheet

-

Raw Material Thickness:

-

0.45-0.55mm

-

Operation:

-

touch screen and button

-

Control system:

-

PLC

-

Main axle material:

-

GR15

-

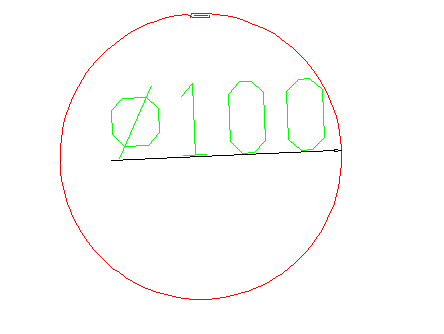

Diameter of shafts:

-

60-80mm

-

machine color:

-

according to customer's requirement

Quick Details

-

Type:

-

decking machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

8-12m/min

-

Rolling thinckness:

-

0.45-0.55mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

zhongtuo

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6800mm*800mm*1200mm

-

Weight:

-

4000 kg

-

Warranty:

-

one year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material of axis:

-

45#steel with chrome treatment

-

Raw Material type:

-

color steel sheet

-

Raw Material Thickness:

-

0.45-0.55mm

-

Operation:

-

touch screen and button

-

Control system:

-

PLC

-

Main axle material:

-

GR15

-

Diameter of shafts:

-

60-80mm

-

machine color:

-

according to customer's requirement

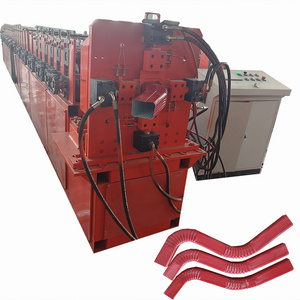

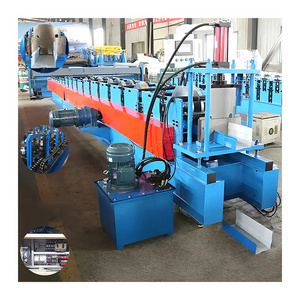

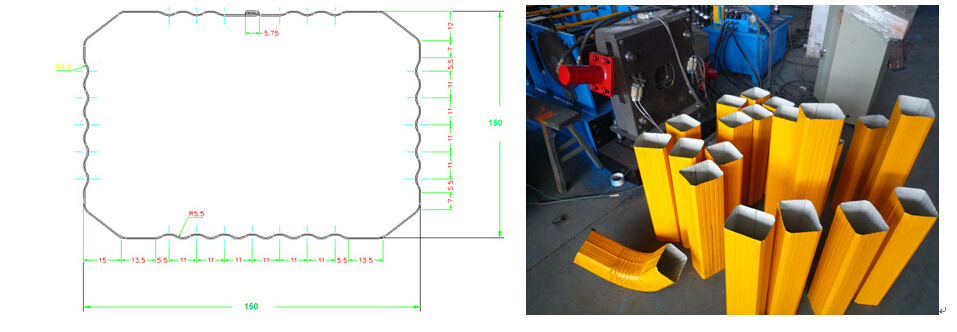

Good quality rain gutter downpipe gutter and elbow roll forming machine

Zhongtuo downspout pipe making machine could be used to make downspout pipes in a higher speed and good quality by 16 years in this area. For this machine, we take guide column frame style to make machine for making sure machine working speed and steady. And for the transmission, we will use gearbox with chain.

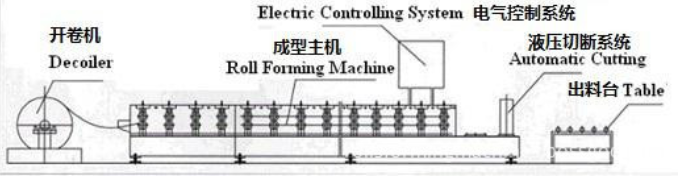

Our downspout roll forming machine mainly consists of uncoiler, roll forming system, cutting equipment, protective guard, hydraulic system, control system and out table. It can make curve for down pipe to meet the requirement of practical engineering projects.

Machine components

Passive uncoiler

Guiding unit

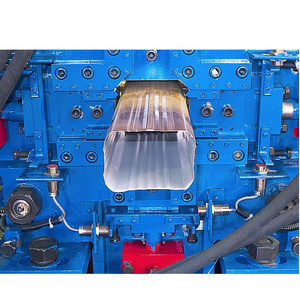

Roll forming machine

Cutting unit

Hydraulic station

PLC control cabinet

Supporter table

Security cover

Elbow machine

Technical process

Passive uncoil— Feeding—Roll forming—Cut to length—Output table—Elbow with pipe

Technical parameters

|

Items |

Specifications |

|

Material Spec |

Galvanized steel sheet, color sheet |

|

Thickness of Coil Sheet |

0.3 –0.8mm |

|

Main Motor Power |

5.5kw |

|

Forming Speed |

10-15m/min |

|

Hydraulic Station Power |

3kw |

|

Quantity of Stands |

18 |

|

Hydraulic Pressure |

10~12Mpa |

|

Controlling System |

Panasonic PLC |

|

Index Error of Length |

10m±2mm |

|

Total Weight |

7T |

|

Voltage |

380V 3 phase 50Hz |

Feedbacks from clients to us about our machines and me:

Packaging: Important Components Wiped Anti Rust Oil, Rollers and Shafters covered by foam

film, Hydraulic station, PLC control Box, Spare parts and some small parts

Packed in plywood box. All Components Fixed by steel wire with Container.

Payment Terms: 30%T/T after signed the contract,balanced before delivery

1). One year, and we will provide the technical support for the whole life.

2).Training: the buyer should charge of visa, return ticket, food and accommodation

overseas and USD100/person/day for salary.

3). Need one technicians

4).Training time: one week (contains the time of installation and adjustment