- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

1.2-3

-

CrO Content (%):

-

0

-

SiC Content (%):

-

3.0

-

Place of Origin:

-

Henan, China

-

Name:

-

Magnesia brick

Quick Details

-

SiO2 Content (%):

-

≤1.5

-

Al2O3 Content (%):

-

0

-

MgO Content (%):

-

92-97.5

-

CaO Content (%):

-

1.2-3

-

CrO Content (%):

-

0

-

SiC Content (%):

-

3.0

-

Place of Origin:

-

Henan, China

-

Name:

-

Magnesia brick

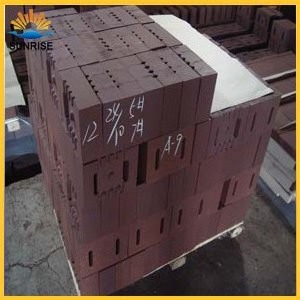

Fused Magnesite/large crystal fused magnesia/Magnesium carbon refractory brick

Application:

As an excellent material ,can be used for magnesia bricks, unshaped refractory materials.

At same time can be used in metallurgy, building materials, chemical industry, national defense, scientific research, aerospace, medical equipment components and household appliances:

Magnesite Brick Features :

Excellent performance of basic slag resistance, high refractoriness, thermal stability, anti-erosion and anti-peeling

Excellent strength of pressure bending, abrasion proof

Excellent performance of high-temperature firing, high rates of associative property, anti-erosion ability

Excellent thermal shock resistance and spalling resistance

Excellent ability of high refractoriness, anti-erosion of alkaline residue;

High temperature load of refractoriness under load. High mechanical strength

High temperature resistance excellent corrosion resistance

Resistance to spalling

Physical and chemical index:

|

Item |

Behaviors |

||||

|

Fused Rebonding Magnesia Brick |

|||||

|

DMZ-95 |

DMZ-96 |

DMZ-97 |

DMZ-98 |

||

|

Chemical composition |

MgO % |

≥95 |

≥96 |

≥97 |

≥97.5 |

|

SiO 2 % |

≤1.5 |

≤1.2 |

≤1.0 |

≤0.5 |

|

|

CaO % |

≤1.5 |

≤1.2 |

≤1.2 |

≤0.6 |

|

|

Apparent Porosity % |

≤18 |

≤18 |

≤17 |

≤15 |

|

|

Cold Crushing Strength Mpa |

≥55 |

≥60 |

≥60 |

≥60 |

|

|

0.2Mpa Refractoriness Under Load T 0.6 |

≥1650 |

≥1680 |

≥1700 |

≥1700 |

|

|

Bulk Density g/cm 3 |

≥2.95 |

≥3.0 |

≥3.05 |

≥3.05 |

|

|

Thermal Stability 950°C Wind cycles |

≥15 |

≥20 |

≥20 |

≥20 |

|

Packaging & Shipping