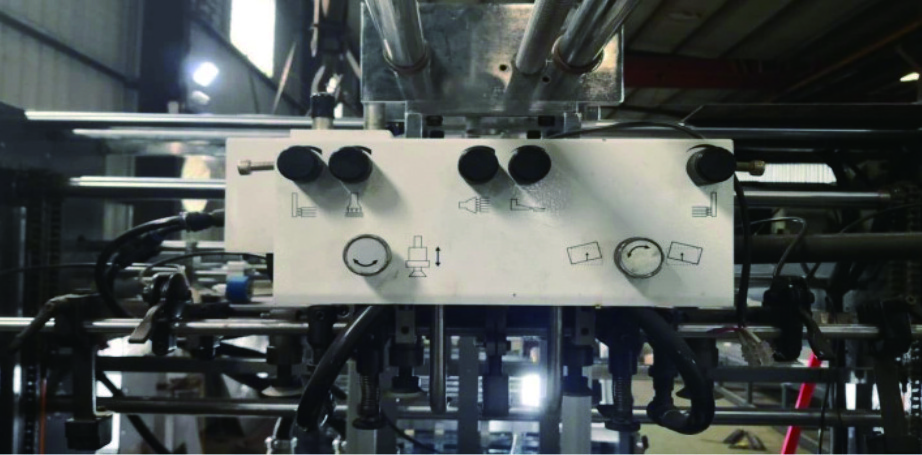

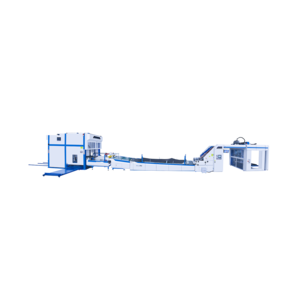

Automatic leading-edge suction feeder ensures stable running at high speed;

No extra adjustment for different sheet sizes, paper weight ranges from 120 gsm to 600 gsm., easy to operate.Sufficient operation

space due to no suction feeder above paper piles; Ideal low E-type piling plate and high speed lifting device ensures quick paper

piling to save time and increase efficiency.

Pre-loading device by rail equipped as standard.