- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Zhangsheng

-

Voltage:

-

380V

-

Motor Power (Kw):

-

110

-

Power (kW):

-

110

-

Weight (KG):

-

6500 KG

-

Name:

-

Wood Pellet Making Machine

-

Capacity:

-

1-10T/H

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Function:

-

Make Wod Pellet

-

Pellet size:

-

6/8/10/12mm

-

Color:

-

Customer`s Request

-

Brand:

-

Zhangsheng

-

Turn-key line:

-

Provide Complete Pellet Production Line

-

Main product:

-

Biomass Pellet Machine

-

Keywords:

-

Pellet Making Plant

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

1000 - 10000 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhangsheng

-

Voltage:

-

380V

-

Motor Power (Kw):

-

110

-

Power (kW):

-

110

-

Weight (KG):

-

6500 KG

-

Name:

-

Wood Pellet Making Machine

-

Capacity:

-

1-10T/H

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Function:

-

Make Wod Pellet

-

Pellet size:

-

6/8/10/12mm

-

Color:

-

Customer`s Request

-

Brand:

-

Zhangsheng

-

Turn-key line:

-

Provide Complete Pellet Production Line

-

Main product:

-

Biomass Pellet Machine

-

Keywords:

-

Pellet Making Plant

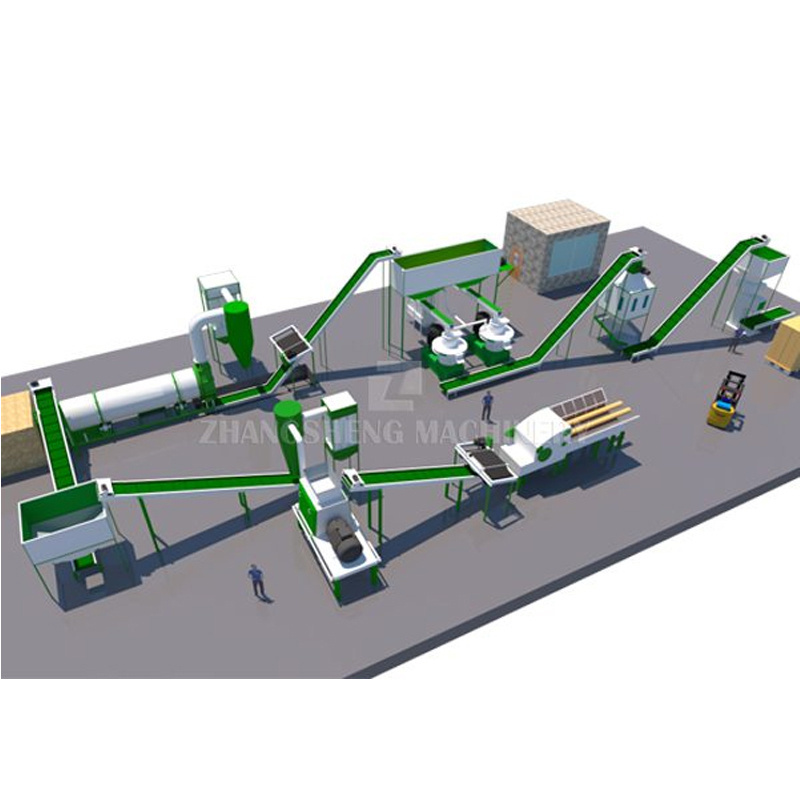

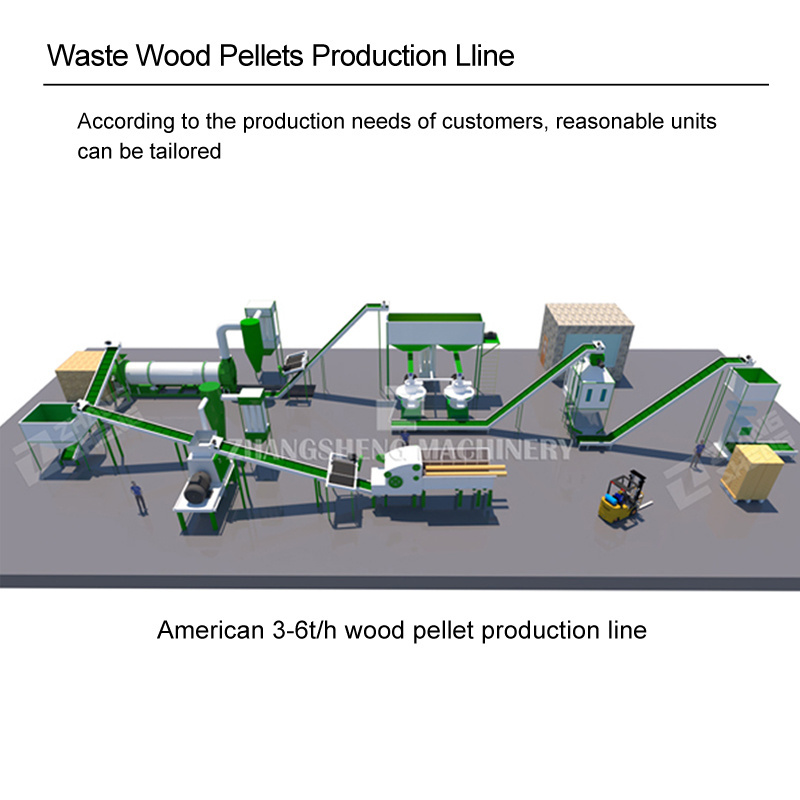

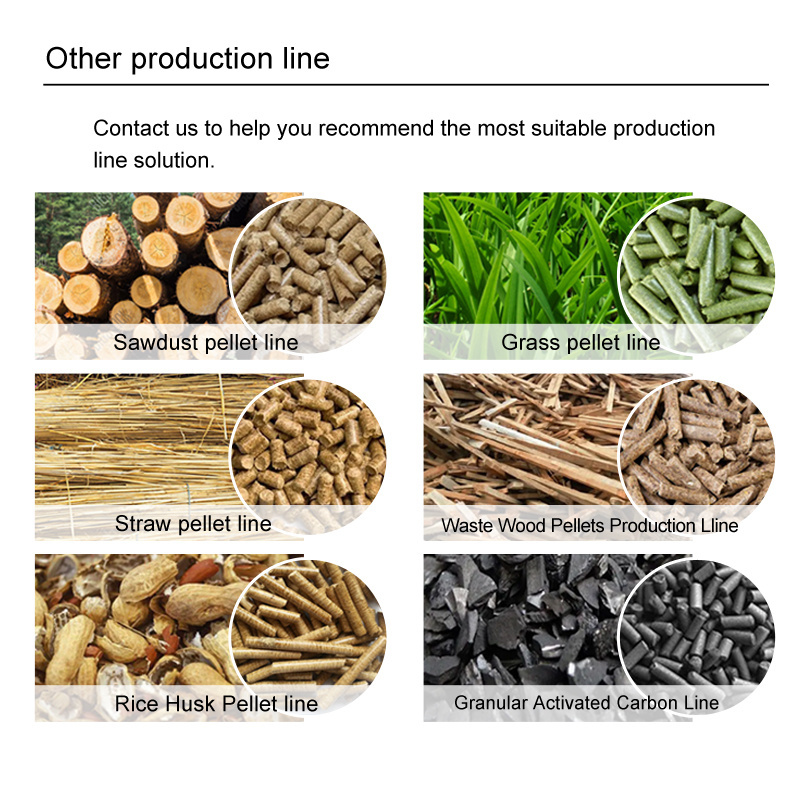

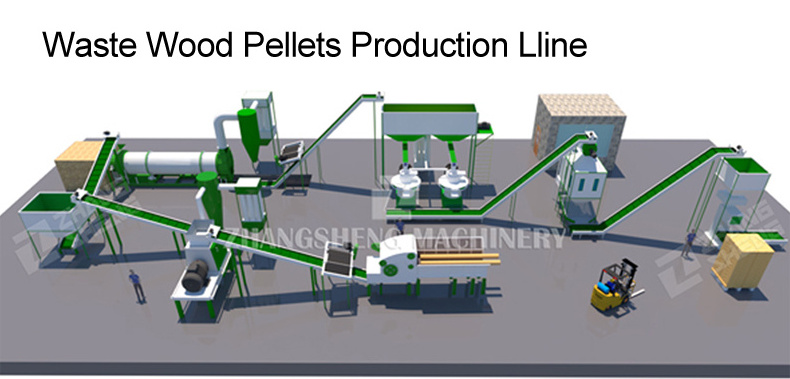

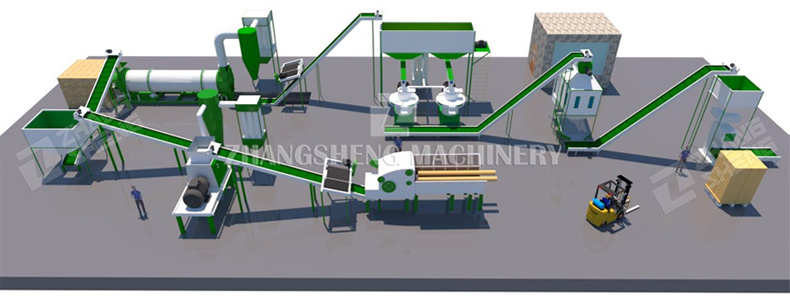

Waste wood pellet production line integrates all processes from raw materials to pellets, including crushing, drying, pellet making, cooling and packing, with an output of 1 to 10 tons per hour. It can process various waste wood, such as planks, wood chips, tree branches, tree trunks, building templates, etc.

Wood pellets have high calorific value, low cost, small size, easy transportation and no pollution. With the increasing shortage of coal, oil and other energy sources, the market demand for wood pellets is increasing, and the profits are considerable.

A lucrative project - biomass pellets production

Wood pellets have a high combustion value and are mostly used in large-scale power plants, medium-scale district heating systems, and small-scale residential heating.

Wood pellets are small in size and low in transportation costs. The raw materials is renewable, and you can save about half your fuel bills compared to petrol or natural gas.

Wood pellets are one of the most effective ways to meet renewable energy and carbon reduction goals.

Between 2020 and 2022, global industrial pellet demand increased by 18.4%, while production increased by only 8.4%. Therefore, the wood pellet production line is a promising and lucrative project.

Why Choose US

Process Flow

Wood Drum Chipper

Primary crushing stage process tree trunks and logs with a diameter of less than 50cm, into small wood chips within 20mm.

Hammer Mill

Hammer mill process small wood chips with a diameter of less than 20mm into sawdust with a diameter of less than 8mm.

Rotary dryer/Air Flow Dryer

The optimum moisture content for granulation is 12-18%. The dryer reduces the wood sawdust moisture from 20%-60% to 12-18%.

Pellet Mill

The pellet mill makes dry sawdust into pellets, and the output of a single machine can reach 3t/h.

Cooler

The cooling system cools the pellets from 70-90 ℃ to room temperature, and the hardness of the pellets will become stronger.

Packing Machine

Pack the qualified pellets from 10kg, 20kg or 1 ton into a plastic bag, and then sew with a thermoplastic sealing machine to make the pellets dry and waterproof.

Note:

This is a conventional simple biomass pellet production line, we can customize different pellet production plans for you according to different sites, raw materials, output and budget. As a leading pellet machine manufacturer in China, ZhangSheng has rich experience in pellet machine manufacturing, and can build a unique pellet mill for you according to the actual situation.

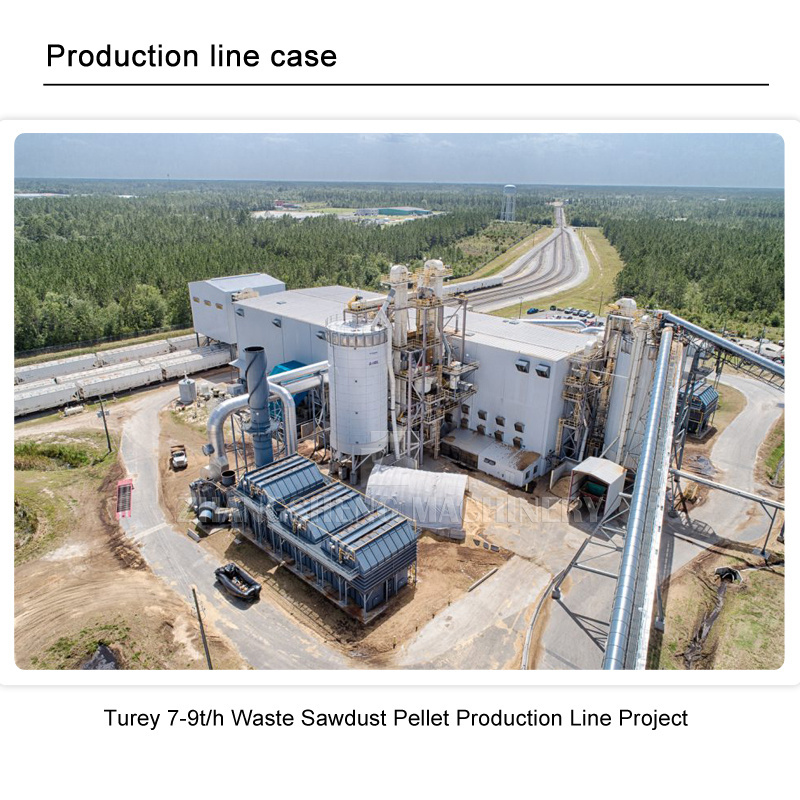

Case show

Experience of manufacturing and installing project globally, which help them get huge economic benefits.

Hot Searches