- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LFM

-

Voltage:

-

220/380V customzied

-

Dimension(L*W*H):

-

1300*950*1290

-

Power (kW):

-

11 kW

-

Material Viscosity (Pa.S):

-

≤0.2

-

Rated Pressure (Mpa):

-

50

-

Rated Flow (L/H):

-

500

-

Temperature (℃):

-

≤80

-

Feed Pipe Diameter (Mm):

-

38

-

Discharge Pipe Diameter (Mm):

-

32

Quick Details

-

Barrel Volume (L):

-

500

-

Max. Loading Volume (L):

-

500 L

-

Weight (KG):

-

1100 KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LFM

-

Voltage:

-

220/380V customzied

-

Dimension(L*W*H):

-

1300*950*1290

-

Power (kW):

-

11 kW

-

Material Viscosity (Pa.S):

-

≤0.2

-

Rated Pressure (Mpa):

-

50

-

Rated Flow (L/H):

-

500

-

Temperature (℃):

-

≤80

-

Feed Pipe Diameter (Mm):

-

38

-

Discharge Pipe Diameter (Mm):

-

32

Products Description

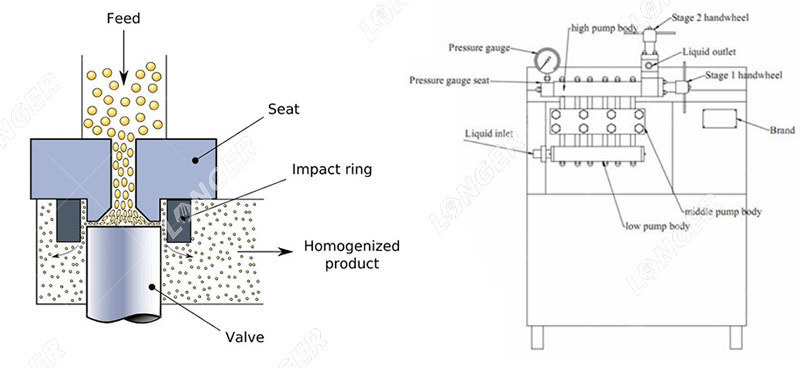

Introduction Of

Milk Pasteurizer And Homogenizer

1.I

ce cream homogenizer

is a device for homogenizing and emulsifying fluid mixture materials. This machine can be widely used in production, scientific research and technology development in the fields of food, dairy, beverage, pharmaceutical, fine chemical and biotechnology.

2.Homogenizing various dairy materials such as milk and soy milk under high pressure can significantly refine the fat globules in the dairy liquid, making the products easy to digest and absorb after eating, and improving the edible value.

Parameters

|

Model

|

LG-0.5/60

|

|

Temperature (℃)

|

≤80

|

|

Moter Power(kw)

|

11

|

|

Moter Spindle speed (R/Min)

|

740

|

|

Dimension(L*W*H mm)

|

1300*950*1290

|

|

Weight(Kg)

|

1100

|

Important Reminder:

1.The technical parameters are for reference only.

2.The product quotation is for reference only, It is based on the actual purchased model and configuration.

3.For more information, please call or consult customer service.

Pressure Range Of Different Materials

|

Material

|

Pressure Range

|

|

|

Fresh Milk

|

≤20Mpa

|

|

|

Flower Milk

|

≤40Mpa

|

|

|

Fruit Juice

|

≤30Mpa

|

|

|

Plant Protein Drink

|

≤45Mpa

|

|

|

Organic Pigment

|

≤90Mpa

|

|

|

Dye

|

≤90Mpa

|

|

|

E.Coli

|

≤60Mpa

|

|

|

Yeast

|

≤90Mpa

|

|

|

Fatty Milk

|

≤100Mpa

|

|

|

To get the 1 um particles, the pressure must be above 100 Mpa.

|

|

|

|

In general, the higher the pressure, the finer and more uniform the particles, such as one-time homogenization, which can be

homogenized multiple times. |

|

|

Working Principle Of

Yoghurt Homogenizer

The motor uses a V-belt to drive the transmission shaft, and the sliding rod through the connecting rod drives the plunger to reciprocate, so that the liquid in the pump body is continuously sucked in and pressed out. Under the action of strong impact, pressure loss, expansion and other composite forces, it is effectively refined and mixed.

Homogenizer For

Honey Homogenizer

1. Compact structure, stable operation, high efficiency, low noise and low energy consumption.

2. The crankcase is cast with ductile iron, which has good rigidity, high strength, wear resistance, no deformation and no fracture.

3. The plunger seal adopts self-expanding and self-lubricating imported sealing material, which greatly improves the reliability of the seal.

4. The plunger adopts flexible connection, which can ensure the reciprocating transmission accuracy of the plunger, and effectively improve the service life of the plunger and the seal.

Detailed Images

Precautions

1. The lubrication of this machine is splash type. When adding oil, it is filtered by a 100-mesh filter screen per inch to ensure the cleanliness of the oil.

2. Change the oil after the machine starts working for 100 hours, and then change the oil every 1000 hours. Generally, HJ40 oil, HJ30 oil in low temperature workplaces, and HJ50 oil in high temperature workplaces.

3. During load operation, the working pressure cannot exceed the rated pressure value.

4. The flow rate of all cooling water on the plunger can be made into thin strips.

5. It is strictly forbidden to operate without cooling water and material supply.

Recommend Products

Exhibition

Customer Photos

Hot Searches