- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

900 x 1800-3200 x 4000 mm

-

Weight:

-

3.6-137 t

-

Warranty:

-

1 Year

-

Certification:

-

ISO9001 CE

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Speed:

-

18 - 38 r/min

-

Max Weight of Balls:

-

1.5 - 65 t

-

Input Size:

-

< 25 mm

-

Output Size:

-

0.047-0.89

-

Product name:

-

Ball Milling Machine

-

Application:

-

Cement

-

Color:

-

Customerized

-

Installation:

-

Under Technical Guidance

-

Spare parts:

-

Supplied

Quick Details

-

Capacity(t/h):

-

0.65-180 t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BAICHY

-

Dimension(L*W*H):

-

900 x 1800-3200 x 4000 mm

-

Weight:

-

3.6-137 t

-

Warranty:

-

1 Year

-

Certification:

-

ISO9001 CE

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Speed:

-

18 - 38 r/min

-

Max Weight of Balls:

-

1.5 - 65 t

-

Input Size:

-

< 25 mm

-

Output Size:

-

0.047-0.89

-

Product name:

-

Ball Milling Machine

-

Application:

-

Cement

-

Color:

-

Customerized

-

Installation:

-

Under Technical Guidance

-

Spare parts:

-

Supplied

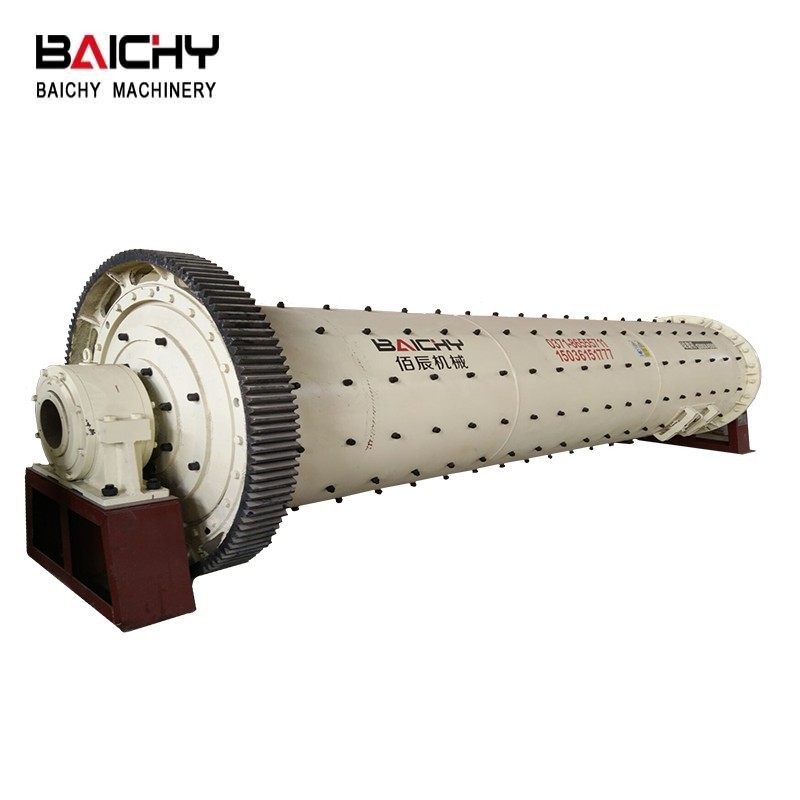

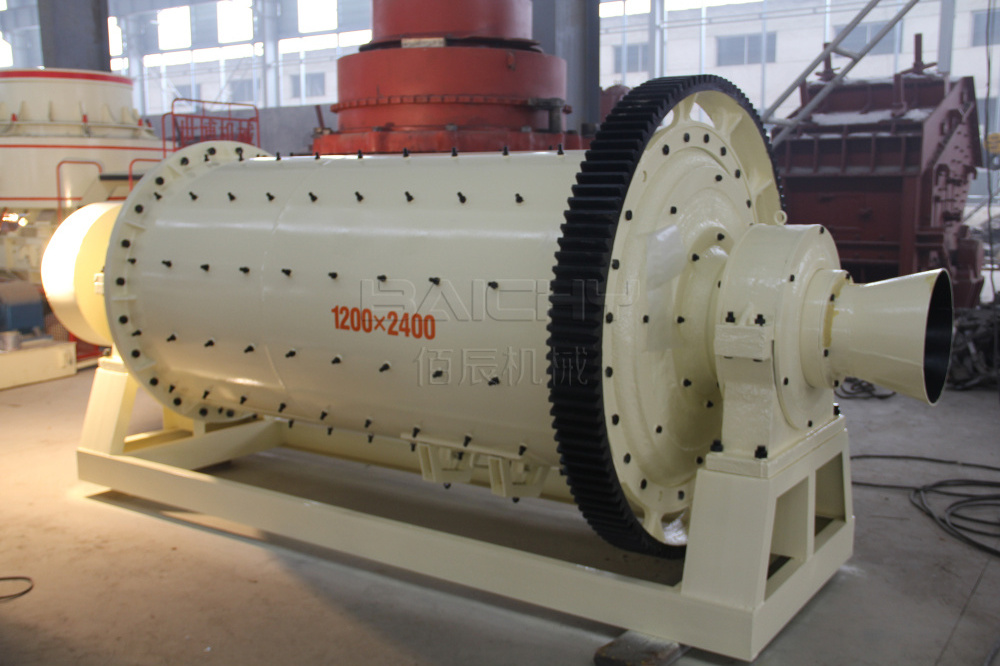

Descriptions of Ball Mill:

Ball mill is mainly used to grind materials such as mineral, cement, refractories, chemical industry, etc.Ball mills has two types:dry and wet.When wet ball mill works, certain water or liquid will be added into materials to increase fluidity, and the capacity is increased. When dry ball mill works,capacity is affected without water to increase the fluidity, so wind device is often installed on the outlet of ball mill to increase the fluidity.

Features of Ball Mill:

1. Negative pressure operation prevents heat dissipation in ball mill with no need of water cooling to ball mill.

2. Mixture ratio of big and small grinding media is based on the technical requirement for fineness of final product.

3. Application of grinding agent in operation can improve grinding efficiency.

4. Diversified device layout, we can offer the optimal design plan based on customer’s technical requirement about production capacity and product fineness.

5. The production line can be arranged in horizontal and vertical version based on customer’s existing workshop.

6. Reliable and stable operation results in little failure rate.

7. Compact structure lowers user’s building investment cost.

8. Strict quality control to every spare part of the total system, equipment quality from outside to inside is compared with Germany’s.

9. Product seriation with annual production capacity of 5-70000 ton for your selection.

10. Available turnkey project.

11. Atomic control and easy operation.

Working Principle of Ball Mill:

1. Material feeding: After the materials are roughly crushed, they will be fed into the ball mills.

2. Impact grinding: when the milling chamber is rotating at high speed, grinding medium and

grindneed materials, which are also rotating, will impact with each other; thus to achieve impact grinding for materials;

3. Classification: after the materials are crushed, they will be discharged into self diffluent classifiers. And then the relatively coarse and fine powders will be separated. Qualified powders will be collected; and unqualified powders will be re-crushed.

Inside Structure of Minerals Processing Plant Ball Mill:

Technical Parameter of Ball Mill:

| Model | Cylinder Rotating Speed (r/min) | Ball weight(t) | Feeding Size (mm) | Discharging Size(mm) | Capacity (t/h) | Power(kw) | Weight(t) |

|---|---|---|---|---|---|---|---|

| 900×1800 | 36~38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| 900×3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| 1200×2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| 1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| 1200×4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| 1500×3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

| 1500×4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 | 21 |

| 1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| 1830×3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 28 |

| 1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

| 1830×6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 34 |

| 1830×7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 36 |

| 2100×3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 155 | 34 |

| 2100×4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 | 42 |

| 2100×7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 | 50 |

| 2200×4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

| 2200×6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 52.8 |

| 2200×7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 54 |

| 2200×7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 56 |

| 2400×3000 | 21 | 23 | ≤25 | 0.074-0.4 | 7-50 | 245 | 54 |

| 2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

| 2700×4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 12-80 | 400 | 94 |

| 2700×4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 12-90 | 430 | 102 |

| 3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | -- | 800 | 137 |

Packing and Shipping of Ball Mill:

Pre-sales Service:

1. The wide product range enables us to provide our customers with stand-alone machines or complete processing plants;

2. Based on our customers'request and budget, our experts make efficient, reliable solutions;

3. Before placing the order every customer has the chance to visit daiwo working machines or complete plant in the site;

4. We have a full set of testing equipment, to provide a good test environment.

After-sales Service:

1. Experienced technicians guidance and engineers will be dispatched to the quarry site to help install the customers'plants;

2. Provide necessary training about machine daily maintenance to local workers ;

3. After-sales department has well-trained employees and professional installation engineers.