- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Heating, Quenching, Forging, Melting, Welding

-

Input Current:

-

90A

-

Water Temperature Protection Point:

-

40degree Room Temperature

-

oscillating Frequency:

-

20-80khz

-

The flow rate of cooling water:

-

0.15 Mpa 25L/Min

-

Duty cycle:

-

100% full load,24hours of continuous work

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Sinfor

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Online support, Video technical support

-

Application:

-

Heating, Quenching, Forging, Melting, Welding

-

Input Current:

-

90A

-

Water Temperature Protection Point:

-

40degree Room Temperature

-

oscillating Frequency:

-

20-80khz

-

The flow rate of cooling water:

-

0.15 Mpa 25L/Min

-

Duty cycle:

-

100% full load,24hours of continuous work

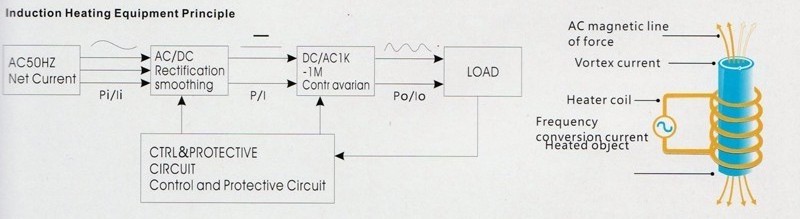

Induction Brazing Machine It is applicable to the welding of such electric heating products as electric heating pan, electric water kettle, frying pan and coffee pot, which can make the stainless steel plate, aluminum sheet and tubular electric heating element of different shapes and thickness form an integral part through one-off metal braze welding. This device is an mechanical Hydraulic and electrical integrated equipment controlled by several sets microcomputer. The main performance index takes the leading position at home and abroad.

It uses the IGBT high frequency induction heating machine to provide heating power and the pneumatic system as the drive, it has such features as stable operation, precise control, easy operation and high rate of products meeting standards, which is the most ideal equipment for manufacturing on new generation of electric heating stainless steel cookware and kitchen utensil.

Products characteristics:

1. The IGBT power module is adopted, with low power dissipation and efficient energy conservation itself.

2. Soft switching parallel resonance, and PFM double control circuit are adopted, which is simple and easy to operate.

3. Output transformer can not only match conveniently the load impedance, but also segregate the high voltage electricity network; it is safe to operate.

4. The circuit is simple and reliable , and is convenient to bear high-power capacity through the parallel connection.

5. It is designed for 100% full power, and can run around the clock.

6. The volume is incredibly small, which can save production space for client.

7. It is fit for the striking and forging, and smelting of all kinds of metals, especially fit for the diathermancy of small workpieces, which needs partial diathermancy.

Main models and specifications:

Advantages

1. Fast heating: the minimum rate of heating is less than 1 second (rate of heating is available for adjustment and control). 2. Wide coverage of heating: it can be used to heat various metal parts (replace removable induction coil as per different operating switches).

3. Easy installation: it can be used once it is connected with power supply, induction coil as well as water supply pipe and rising pipe; it is small in size and light in weight.

4. Easy operation: you can learn to operate it within several minutes.

5. Fast start-up: it can be started to perform heating operation on condition that water and power supply is available.

6. Low power consumption: As compared with conventional vacuum tube high frequency equipment, it can save the power by approximately 70%. The smaller the size of the work piece is, the lower power consumption would be.

7. High effectiveness: it has such features as uniform heating (it is applicable to adjust the spacing of the induction coil to ensure the appropriate temperature as required by each part of work piece), fast warming and limited oxic horizon, and can guard against any waste after annealing.

8. Comprehensive protection: it has such functions as over voltage, over current, over heat and water shortage alarm indications as well as automatic control and protection.

9. Controllable temperature: it is applicable to control the temperature for heating work pieces as per the preset heating time, and thereby control the heating temperature at a certain technical point.

10. Comprehensive full load design: it can work continuously for 24 hours.

11. Small size and light weight: it has a weight of only several dozens of kilograms, the limited floor space can effectively save the workshop space.

12. Elimination of high voltage: it requires no step-up transformer which may produce approximately ten thousand voltage, and thus can ensure the maximum safety.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Sinfor is specialized in researching and manufacturing of solid-state medium to ultrahigh frequency induction heating equipment and systems. our company was established in 2000 and is privately held. Precision induction heating solutions are our specialty. Use induction heating to improve the efficiency and effectivenesfor industrial heating process. That are used for application such as brazing. annealing,hardening,forging, melting, shrink fitting etc.

Our induction heating machine are Available from 3kw to 1500kw deliverable output power with 0.5KHZ to1.1MHZ operating frequency range. All our products are divided into four major series according to the frequency:

Medium frequency series (abbr. MF series):0.2-20KHZ

High frequency series (abbr. HF series):30-100KHZ

Superaudio frequency series (abbr. SF series):5-40KHZ

Ultrahigh frequency series (abbr. UF series):100-1100KHZ