- Product Details

- {{item.text}}

Quick Details

-

Connect machine:

-

Feeder,Vibratingscreen

Quick Details

-

color:

-

Blue

-

Usage:

-

Construction

-

Installation:

-

Under Engineer's Guide

-

Connect machine:

-

Feeder,Vibratingscreen

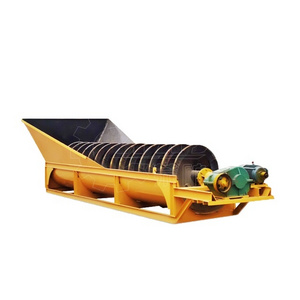

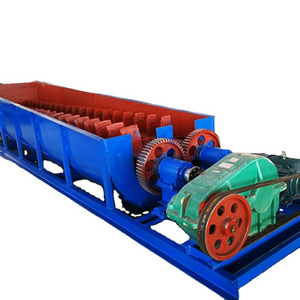

Good quality Spiral Sand Washing Machine for coal mining and crushing process

LX series Spiral sand washer is a kind of efficient sand and gravel washing machine, which is widely used for sand and stone washing, gradation and impurities removing. Spiral sand washers are specifically to produce quality sand for construction, highways, railways, building materials, water and electricity industries and more.

Spiral sand washing machine can be divided into single spiral and double spiral washing machine, and with the features of power consumption, high cleanliness, good sealing structure, fully closed transmission device, adjustable weir plate ensure the durability of the product, good cleaning and dehydration effect, fine product stability and other characteristics.

Working Principle

Spiral sand washer is based on the principle of different specific gravity of solid particles and the different sedimentation rate in liquid to realize washing process. The spiral sand washer is equipped with water spray pipes in cleaning tank. When working, a certain amount of water is supplied to flush and submerge the raw sand loaded into the tank from the inlet. At the same time, the spiral is continuously stirred and graded, and dirt impurities and tiny sand particles are suspended in the upper turbid water, gradually overflowing from the low-end overflow weir; the coarser sand particles sink to the bottom of the tank by gravity. As the spiral rotates continuously, the coarse sand is continuously agitated and graded in the water, so that the sand is fully washed.

Main Features

1) Reasonable structure, convenient maintenance, large processing capacity, small power consumption, high cleanliness.The novel sealing structure of the spiral stone washer, the whole sealing oil bath type transmission device and the adjustable overflow weir plate ensure that the series of products are durable, with good cleaning and dewatering effects, and the fine products are not disorderly.

2) The processing capacity is large, because the spiral sand washing machine sand washing principle is not to use a bucket to "catch", so its processing capacity has been greatly improved.

3)The higher energy utilization rate reduces the energy loss caused by the wheel bucket in the process of lifting, so that the energy can be better utilized.

4) Reduce the wear of some parts, spiral sand washing machine, do not need to increase the screen, so reduce the loss of the screen, prolong the life of the equipment.

5) The cleaning effect is better, spiral sand washing machine compared with wheel bucket type, the sand material after the turnover cleaning time and times more, better cleaning effect.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* 24hours for technical Operation Guide and 4hours offer technical proposal for problem shooting.

91.8% Response Rate

91.8% Response Rate

91.8% Response Rate