- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

120

-

Dimension(L*W*H):

-

standard

-

Name:

-

1500mm high efficiency metal separator sieving machine

-

Material:

-

Stainless Steel 304

-

Layer(s):

-

1-5 Layers

-

Usage:

-

Fine Particles Screening

-

Motor:

-

Vertical Vibrating Motor

-

Color:

-

Gray

-

Capacity:

-

10Kg-10Tons/hour

-

Function:

-

Screening\separation\sorting\sieving

-

Keyword:

-

Rotary Vibrating Separator

-

Certification:

-

ISO CE

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

COBROCOBRO

-

Voltage:

-

220V/380V/415V/450V

-

Weight:

-

120

-

Dimension(L*W*H):

-

standard

-

Name:

-

1500mm high efficiency metal separator sieving machine

-

Material:

-

Stainless Steel 304

-

Layer(s):

-

1-5 Layers

-

Usage:

-

Fine Particles Screening

-

Motor:

-

Vertical Vibrating Motor

-

Color:

-

Gray

-

Capacity:

-

10Kg-10Tons/hour

-

Function:

-

Screening\separation\sorting\sieving

-

Keyword:

-

Rotary Vibrating Separator

-

Certification:

-

ISO CE

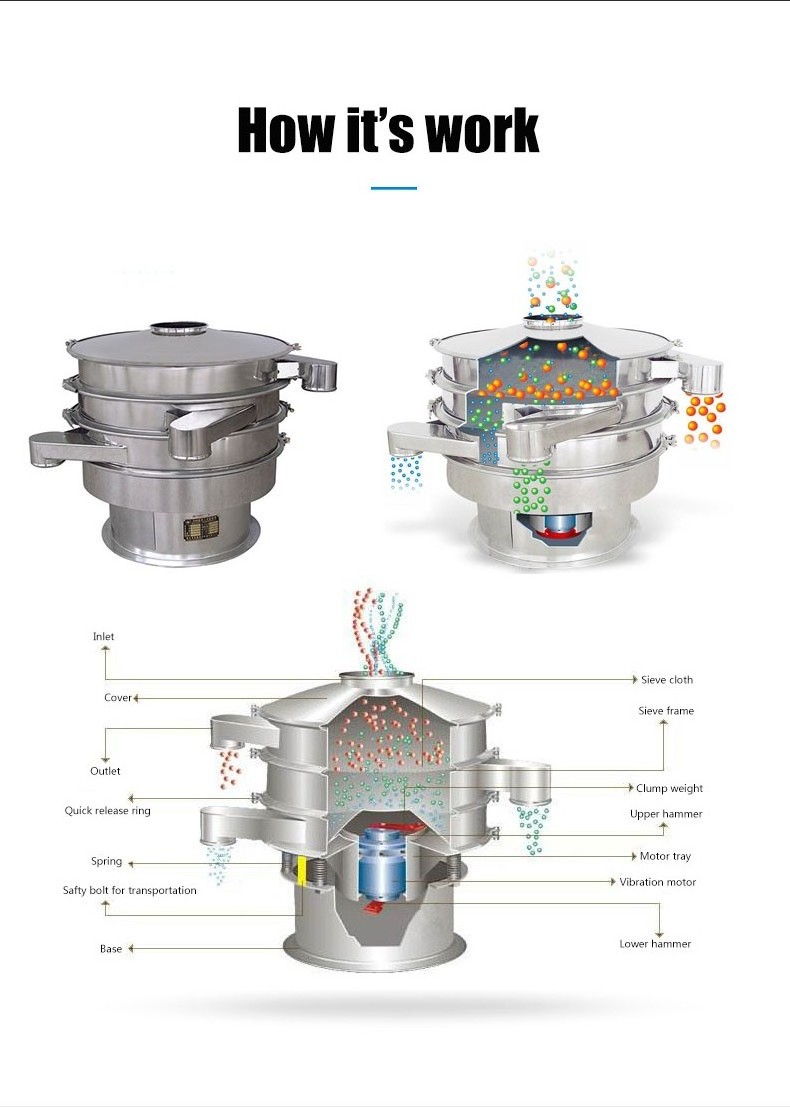

Working Principle of Vibrating Screen

The machine is drived by a unbalance motor, which is with variable eccentric weights on both sides of motor shaft. , The screening time and movement of material on the screen surface can be controlled by adjusting the angle of the two eccentric weights.

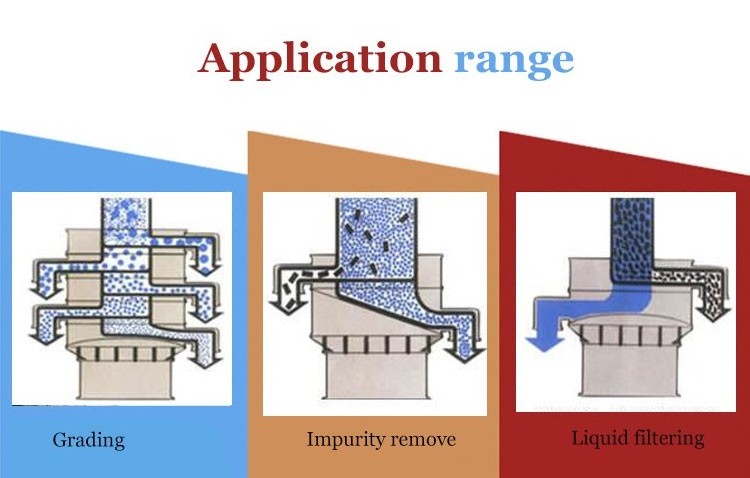

Applictioin of circular oscillating vibrating screen machine

Chemical industry: resin, pigment, industrial medicine, cosmetic, coatings, medicine powder, granules.

Food industry: sugar powder, starch, salt, rice, milk powder, egg powder, sauce, syrup.

3. Metallurgy, Mining industry: aluminum powder, copper powder, ore alloy powder, welding rod powder.

4. Medical industry: all kinds of medicine

5. Waste treatment: disposed oil, disposed water, disposed dye waste water, active car

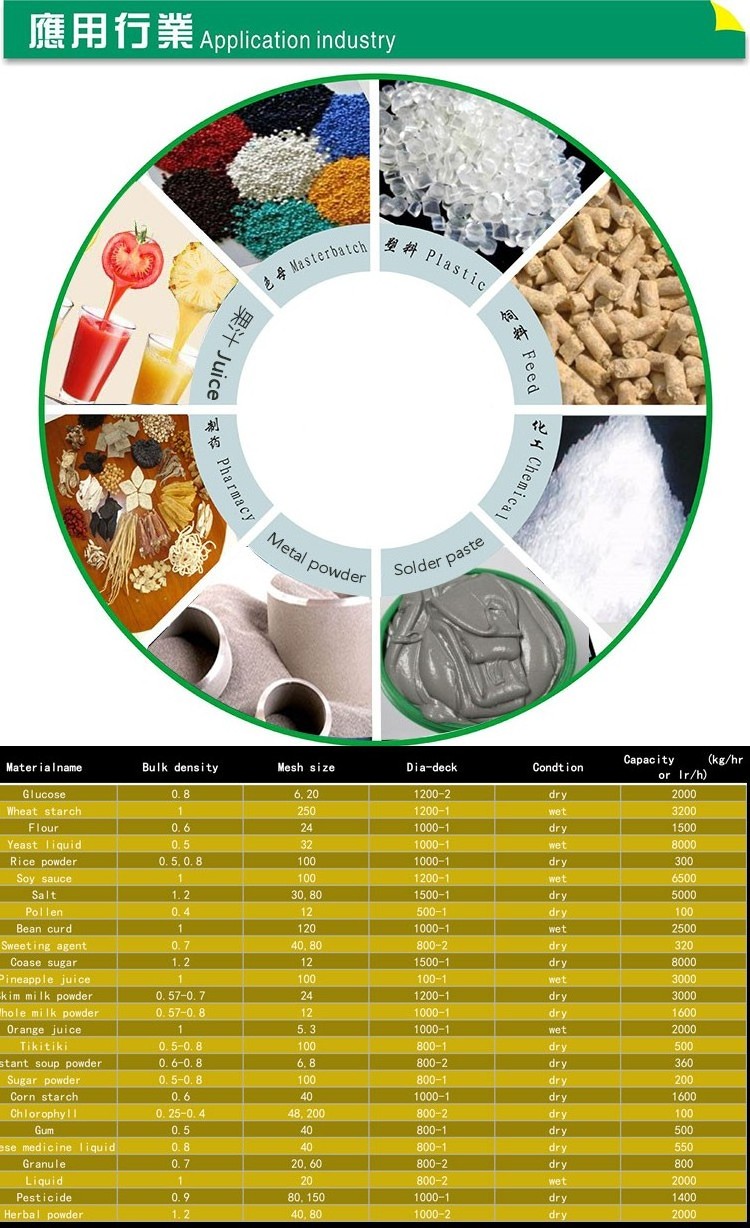

Technical Parameter of circular oscillating vibrating screen machine

Please read this before you choose the suitable model.

1.Please review your material properites: bulk density, water content, granule size range,

2.Required data: The result you wanna get by this machine, output per hour, mesh size and screen deck number

3.Power supply: if you are not clear on it, please consult your electric staff to get the clear idea on it, if your power supply is not right to this machine, motor will be burned down.

4.Construction material: Stainless steel 304 for material contact parts and carbon steel for other parts. If there is special requirement, free to advise. There are multi options for you.

Main Features of small auxiliary vibrating sand screen stone

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .