- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V

-

Power:

-

80KW

-

Dimension(L*W*H):

-

770*670*1430mm

-

Warranty:

-

3 Years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

zirconia /yttria powder application on plasma machine

-

advantage:

-

with high bonding stretch and low porosity

-

Weight:

-

1000kg

-

Certification:

-

ISO9001:2000

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SANXIN

-

Model Number:

-

SX-80

-

Voltage:

-

220V/380V/415V

-

Power:

-

80KW

-

Dimension(L*W*H):

-

770*670*1430mm

-

Warranty:

-

3 Years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

zirconia /yttria powder application on plasma machine

-

advantage:

-

with high bonding stretch and low porosity

-

Weight:

-

1000kg

-

Certification:

-

ISO9001:2000

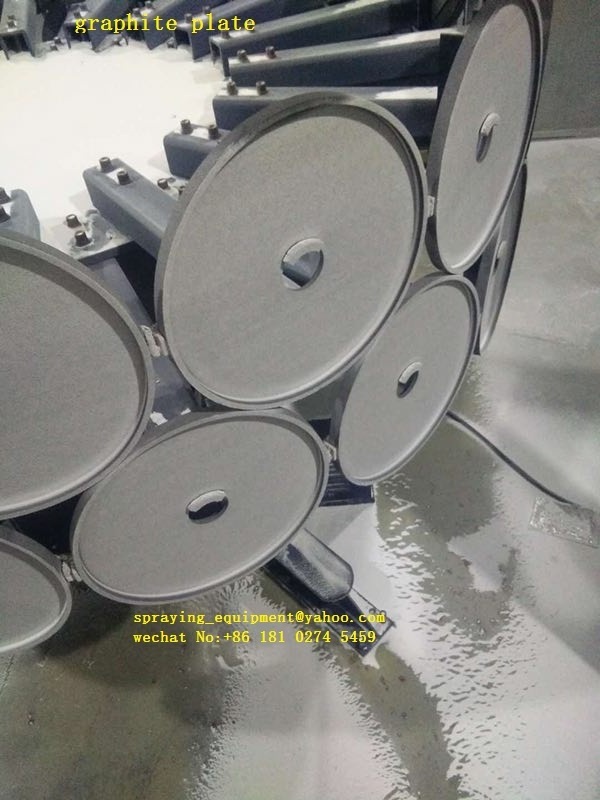

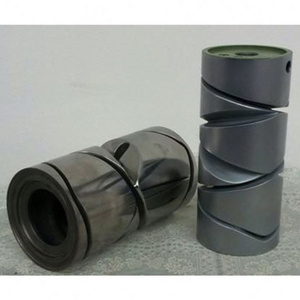

graphite plate zirconia/yttria plasma spray in hard alloy field , plasma coating machine

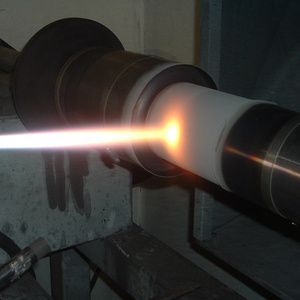

Ceramic, metals, metal compounds and polymers spraying materials, such as tungsten carbide, chromium carbide are commonly used in the plasma spraying industry, which is widely used in the surface of the substrate, to make the material a longer life under harsh operating conditions.

With the development of spraying materials ,there are more and more new material ,such as zirconia ,yttria and so on , which are especially applied in plasma spray machine , greatly extend the application range of plasma machine in various fields . Here I will introduce the plasma spraying machine spraying zirconia ,yttria powder on graphite plate applied in hard alloy field .

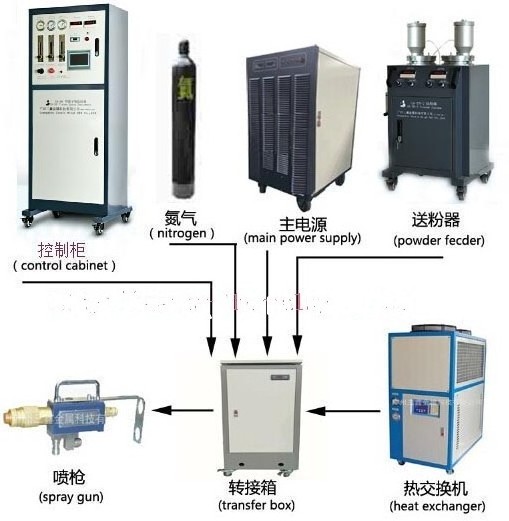

1.component of graphite plate zirconia/yttria plasma spray in hard alloy field , plasma coating machine SX80

(1)Power supply

Silicon controlled rectifier, maximum power input: 85KW, arcing time factor: 100%, plus or minus 15% Grid fluctuation, Maximum power output: 80KW. It can work normally under Current fluctuating range: 1~2%. The power supply provides DC current for spray gun. It is controlled by intelligent module, working 24 hours without breakdown. It is the best plasma power supply in China.

(2) SX-80 control cabinet

Control cabinet is the control center of SX-80. Its input voltage and power are single phase 220V, 1Kw. It is equipped with float flowmeter, it’s digital displaying for indicating current and voltage. It has three working modes of manual control, automatic control and economic operation. It’s equipped with alarming and breakdown display unctions. It will alarm when:

( 1). Pressure of main and secondary gas is lower than 0.3Mpa, or main gas flow is under 30L/min.

(2). Water temperature is higher than 50, or water flow is under 8L/min.

The control cabinet is used for controlling and adjusting water, electricity, gas and spray powder. It monitors the whole spray system so users can directly get the working parameters of the system, that is to say, you can directly read the voltage, current and so on. When the power supply or gas supply cannot meet the system requirement, there will be automatic alarming warning,which can remind the user to make corresponding adjustment. By operating the control cabinet panel, users can adjust the current and voltage to regulate the temperature of plasma arc. They can also adjust the main and secondary gas to regulate the gas flow and gas proportion for changing the length and velocity of plasma arc.

Parameter of SX-80 control cabinet

| Number | Items | Basic parameter |

| 1 | input power supply | AC220V,50Hz/80Hz |

| 2 | input power | 300W |

| 3 | control mode | PLC Control Replay |

| 4 | Main gas and gas pressure | argon,nitrogen,0.6-0.8MPa |

| 5 | Maximum consumption of main gas | 2m3/h |

| 6 | secondary gas and gas pressure | hydrogen,helium,0.25-0.4Mpa |

| 7 | Air and pressure | dried 0.5Mpa |

| 8 | Gas using mode |

argon,argon hydrogen,nitrogen nitrogen+hydrogen |

| 9 | Dimension | 610*450*1700mm |

| 10 | Weight | 65KG |

(3) SX-80 powder feeder

The powder feeder is used to store spray powder and send these powder to spray gun according to technological requirements. The SX-80 system is equipped with one binocular powder feeder. The range of powder particle size is 5~200m. The two tube can feed powder at the same time, the feeding speed is 8~250g/min. Users can adjust the potentiometer on control cabinet panel to regulat the feeding speed.

(4) Transfer box

The transfer box is the transfer center of this plasma spraying equipment. It links power supply, control cabinet, heat exchanger and spray gun together. There are high frequency ignition , waterway and gas circuit alarming devices inside this box. The transfer box is moveable, with standard 5 meter long water-cooled cable.It mixes the water and electricity and sends them to the spray gun,meanwhile it offers high frequency impulse voltage which is needed when the spray gun forms the arc,and tests spay gun’s returned water’s temperature and cooled water’s pressure.It’s easy and flexible,easy to draw,is good at forming arc ,and can reduces the moment currency’s impact when the nozzle is forming arc.

(5) SX-80 heating exchanger

Heat exchanger is also called refrigerator or water chiller. We use double motors compressor to make this machine smaller and save space for our customer. The spray gun is cooled down by water, and we use heat exchanger to cool down the high temperature water coming from spray gun, and then use these cooled water to cool down the spray gun again. In this way the spray gun can keep a normal working temperature and prolong the usage life of spray nozzle.

Function characteristic

(6)SX-80 spray gun

We can offer customer imitative METCO 9 MB spray gun, using argon or nitrogen as main gas, hydrogen as secondary gas. The working current of spray gun: 100-800A. The working voltage: Ar+H2: 50-75V, N2+H2: 50-80V. We provide the following spray gun accessories for our customer: spray nozzle, powder and cooling air jetting shelf, water-cooled cable, electrode tip, insulator, sealing ring, and other special tools.

(7)Parameters of cooling system

2. Characteristics graphite plate zirconia/yttria plasma spray in hard alloy field , plasma coating machine SX80

(1) Can spray a variety of spraying materials, particularly can spray high melting point of refractory materials, such as refractory metals, ceramics, metal ceramics and other special functional materials;

(2)The inert gas can be chosen as working medium ,to reduce the oxidation reaction of spraying particles during flight.

(3)The bonding strength of the coating is high, the porosity is low, and the fine coating can be prepared by controlling the process parameters.

3. Applications of graphite plate zirconia/yttria plasma spray in hard alloy field , plasma coating machine SX80

plasma machine is of wide application .because of its excellent performance. Here I will advise its new application in hard alloy workpieces spraying machine spraying zirconia ,yttria powder on graphite plate applied in hard alloy field .

(1) spraying material:

zirconia /yttria powder

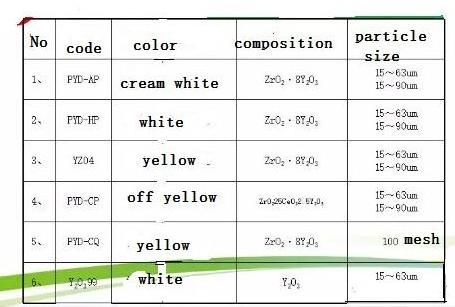

(2) parameter of zirconia /yttria powder

(3) zirconia /yttria powder applition on plasma spraying machine in hard alloy field

Our company is specialized in all kinds of thermal spraying equipment,: such as plasma spraying equipment, supersonic flame (HVOF) spraying equipment, high-speed arc spraying equipment, flame spraying equipment and so on,

we can also supply various kinds of special spraying powder cored wire and solid wire ;

we are selling all kinds of spraying manipulator, spraying turntable, transfer bed, sandblasting machine and soundproof spraying room, Environmental protection and dust removal system and so on;

We have been committed to the development and application of surface engineering technology, we have always been learning the advanced overseas technology, and constantly do research on the spraying technology based on different complex environment, now we have a number of national patents, products are welcomed by many fields , and sold well both at home and abroad .

We are a group member of China Surface Engineering Association, also the member of the National Thermal Spraying cooperation group, we passed the ISO9001:2000 Quality Management system test, owning the thermal spraying construction certification,. Our machines include: the United States Praxair supersonic spraying equipment, Miller plasma spraying equipment, and others ,more than ten styles , we are capable to undertake a variety of surface engineering areas projects ,to improve wear-resistant, anti-corrosion, wear high-temperature, anti-cavitation , other functional thermal coating of the workpieces , or to repair the broken parts of the workpieces.

If you are interested in our machine ,Please contact me for further details ,thanks