- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

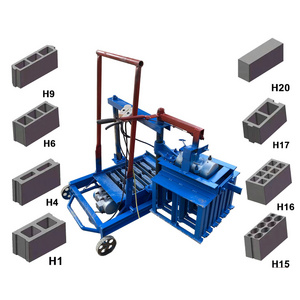

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dingxie

-

Voltage:

-

220/440V

-

Dimension(L*W*H):

-

2060x1730x2580mm

-

Weight (KG):

-

800 kg

-

HS Code:

-

8474802000

-

PLC Control System:

-

Siemens

-

AC Contactor:

-

Schneider

-

Water Consumption:

-

10-20t/Day

-

Workshop Area:

-

250-300m2

-

Product Name:

-

Factory Directly Supply Styropor Insulated Concrete Moulding Machine

-

Rated Pressure:

-

21MPa

-

Cycle:

-

15-18 Seconds for One Sheet

-

After Warranty Service:

-

Video technical support

-

TOTAL WEIGHT:

-

800KGs

Quick Details

-

Type:

-

Hollow Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

Concrete and cement

-

Production Capacity (Pieces/8 hours):

-

15360-100800

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dingxie

-

Voltage:

-

220/440V

-

Dimension(L*W*H):

-

2060x1730x2580mm

-

Weight (KG):

-

800 kg

-

HS Code:

-

8474802000

-

PLC Control System:

-

Siemens

-

AC Contactor:

-

Schneider

-

Water Consumption:

-

10-20t/Day

-

Workshop Area:

-

250-300m2

-

Product Name:

-

Factory Directly Supply Styropor Insulated Concrete Moulding Machine

-

Rated Pressure:

-

21MPa

-

Cycle:

-

15-18 Seconds for One Sheet

-

After Warranty Service:

-

Video technical support

-

TOTAL WEIGHT:

-

800KGs

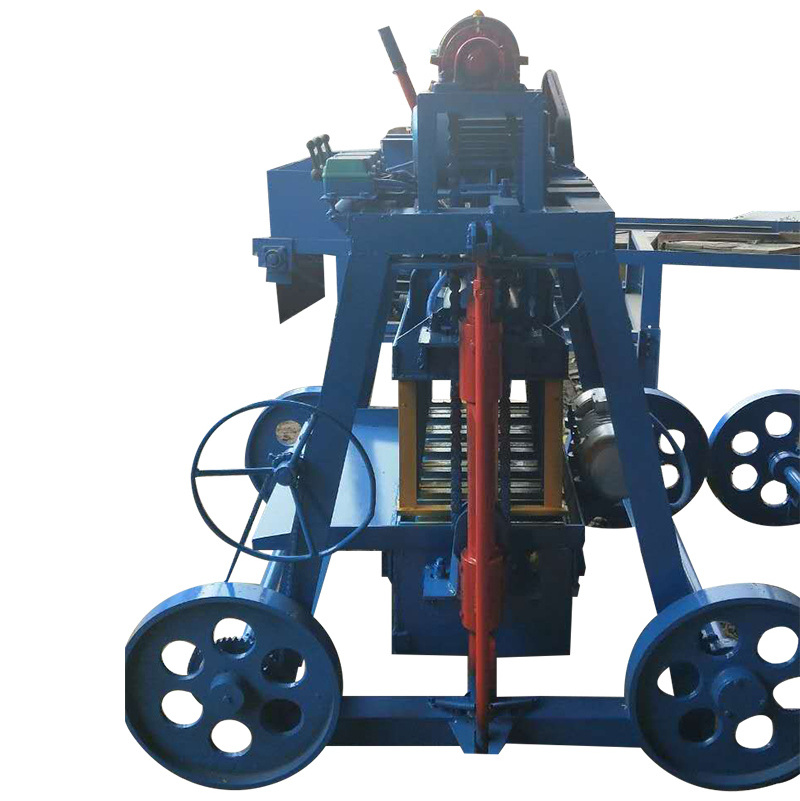

Movable Manual Brick Laying Block Making Machines For Cement Block Price

1.Factory Directly Supply Styropor Insulated Concrete Moulding Machine

2.DX-A moveable Block Brick Forming Machine

T echnical parameter

| Overall size | 5300*2050*2700mm | Host machine power | 56KW | Molding period | 12-20S |

| Pallet Size | 1100×850×25mm | Vibration Force | 90-110KN | Pallet quantity | 1500pcs |

3.

Theoretical workshop area :200m

2

, Need about 3-4workers.

office.curing and stacking area to arrange according to demands

4.QT10-15 concrete block making machine production capacity

| Size(mm) | Pcs/Mould | Pcs/ Hr | Pcs/ 8 Hr |

| 450*225*225mm | 10PCS | 2400 | 19200 |

| 200*100*80mm | 33PCS | 5400 | 43200 |

| 200*100*60mm | 33PCS | 5400 | 43200 |

| 400*150*225mm | 16pcs | 3840 | 30720 |

|

1.We can design mould as per client requests

2.Capacity above is indicative only,The actual capacity varies with operator efficiency and material quality etc |

|||

5.Raw material formula

1.Cement :8%-10% sand:30%-40% small chips:50-60%

2.Sand:60% fly ash :30% cement:8-10% lime:2%

3.Color material formula:50kgs cement,100kgs sand ,3kgs color material

Remark:the formula varies as per the local raw material quality.

6.Block curing

The block can be taken offer pallet after 18-24hours.In hot place like middle east,blocks can be

taken after several hours

In the first 3-5 days,spray water on the block.Then dry the block for 10-15 days.The block is done.

The blocks can be finished product after 9 hours if there is curing room