- Product Details

- {{item.text}}

Quick Details

-

Key components:

-

drum motor, conveyor frame, conveyor roller, conveyor belt

-

Our advantage:

-

decades of experience for design, make and service, direct factory

-

Our strength:

-

professional in processing, packing, and service

-

Product advantage:

-

design according to customer need, high quality, reasonable price

-

OEM:

-

yes

-

Explosion-proof:

-

yes

-

Drive:

-

belt conveyor drive pulley used our own motorized drum

-

Application:

-

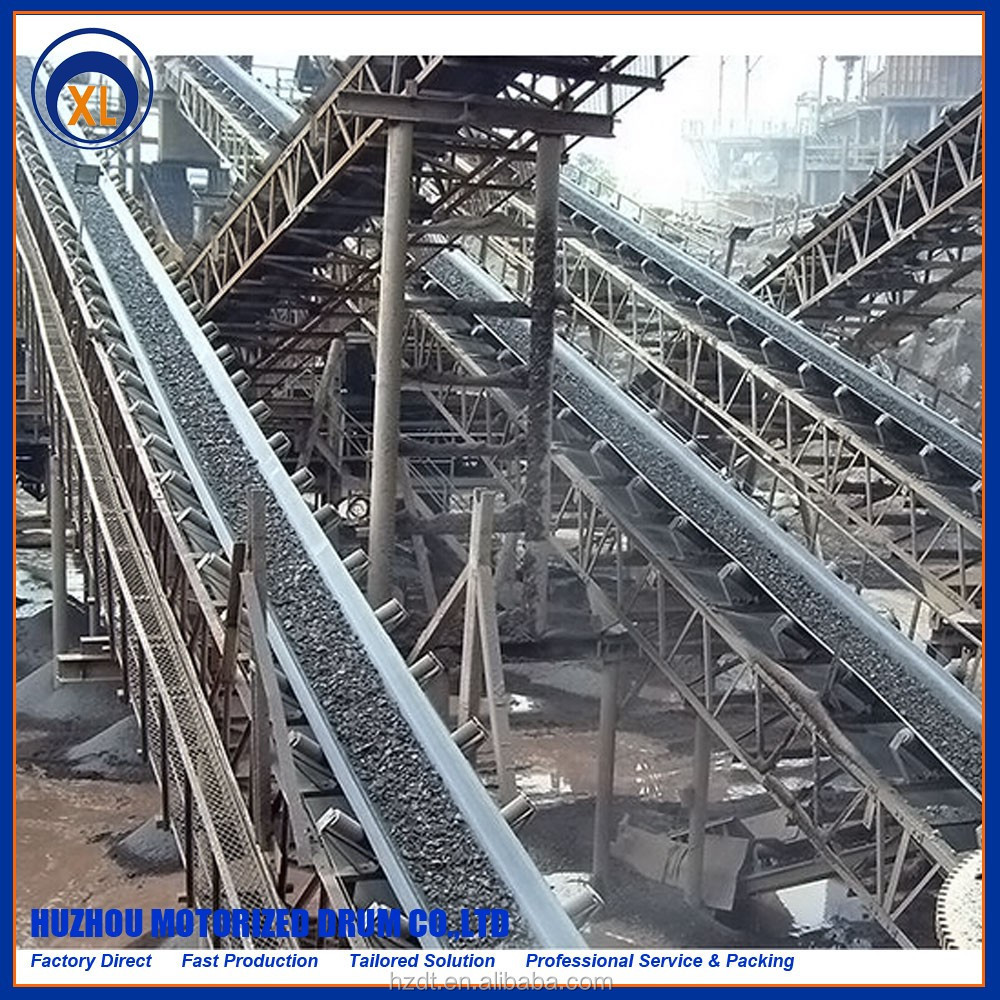

Mining ore,Coal mining,Rocks,Stones,etc.

Quick Details

-

Power:

-

customer requirements

-

Place of Origin:

-

Zhejiang, China

-

Description:

-

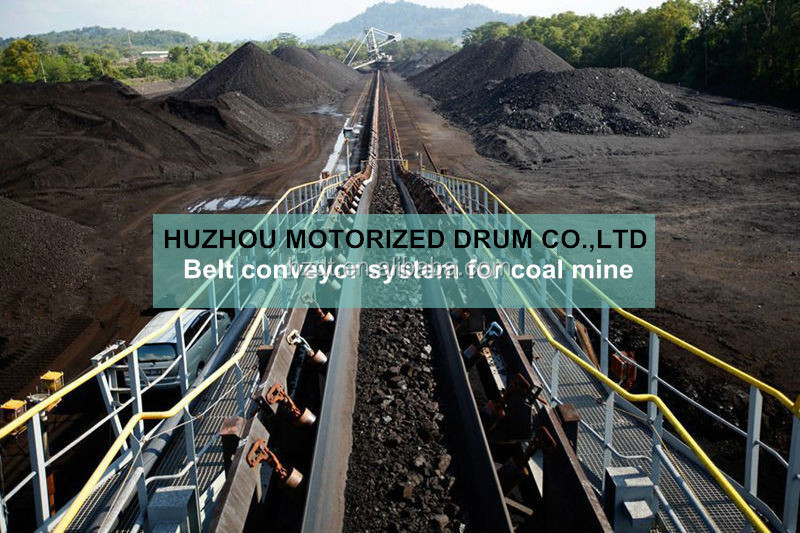

high quality coal mine equipment belt conveyor system

-

Key components:

-

drum motor, conveyor frame, conveyor roller, conveyor belt

-

Our advantage:

-

decades of experience for design, make and service, direct factory

-

Our strength:

-

professional in processing, packing, and service

-

Product advantage:

-

design according to customer need, high quality, reasonable price

-

OEM:

-

yes

-

Explosion-proof:

-

yes

-

Drive:

-

belt conveyor drive pulley used our own motorized drum

-

Application:

-

Mining ore,Coal mining,Rocks,Stones,etc.

We, huzhou motorized drum co.,ltd which used to be a state-owned enterprise, specialized in make and export mining machinery parts, belt conveyor system for heavy-duty industry like coal mining and logistic conveying equipment division, drum motor etc. It's a professional manufacturer in China with decades of years experience in

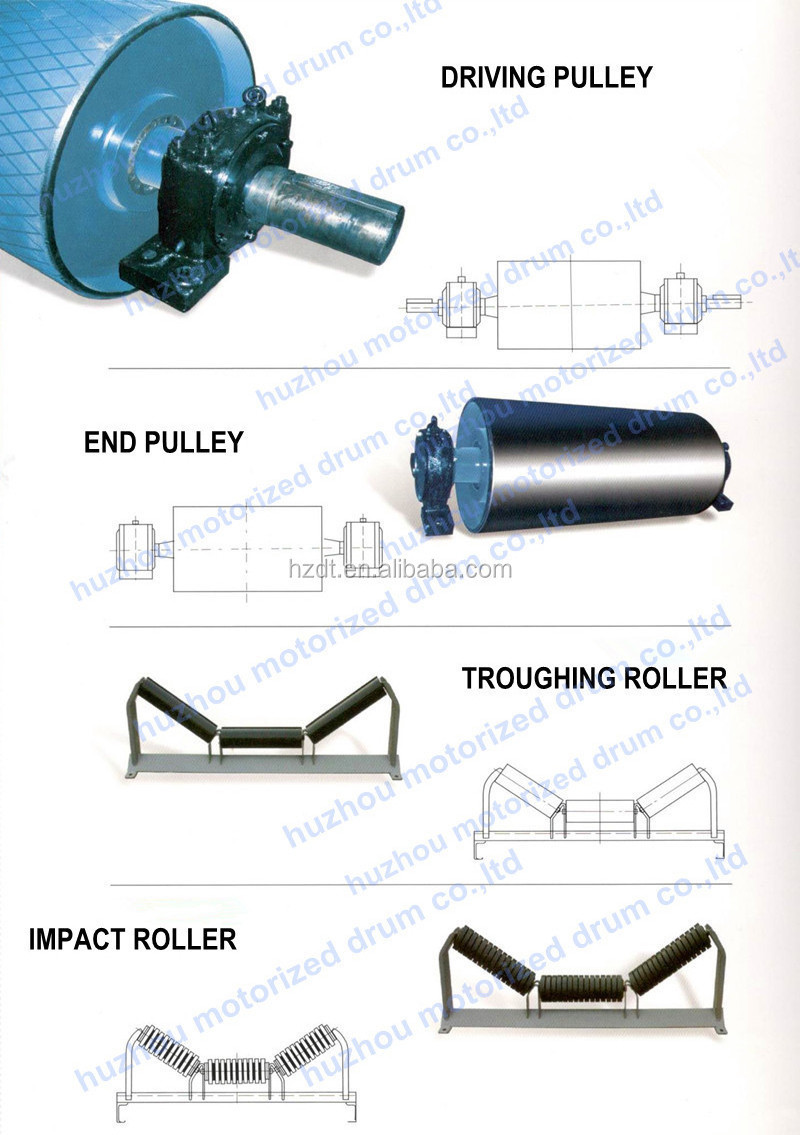

The key products for the coal mine equipment belt conveyor are: belt conveyor roller, conveyor belt, frame and its drive divice motorized drum pulley

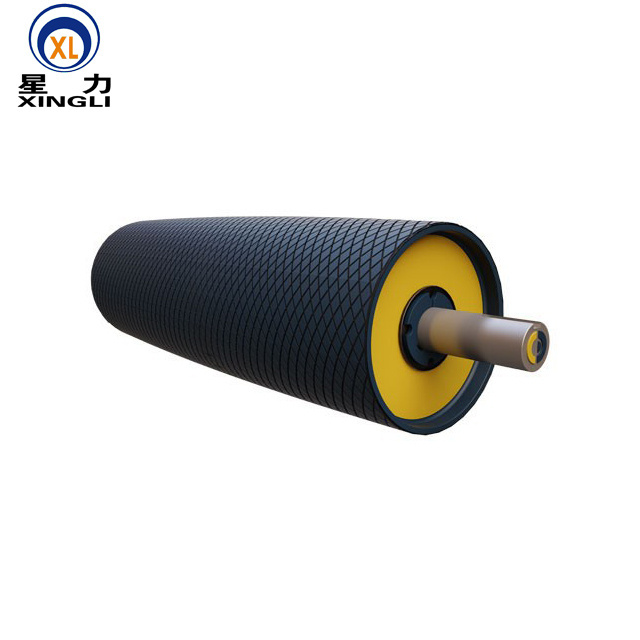

Belt conveyor roller

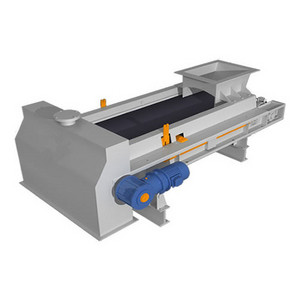

Motorized drum pulley, the drum motor for belt conveyor drive pulley

The motorized drum is advanced products which is combined the drum body, motor and gear box as a single object, in this way it is cost less for cost, install and maintenance, it is much more safe.

We has been synonymous with drum motor belt conveyor drives for more than 30 years.

Motorized pulley can be integrated nywhere as a single component drive station, saving valuable space. They are considerably less prone to break down and in terms of overall cost they are better

value for money than drive systems made up of many individual parts and assemblies.

Features and benefits of XINGLI Drum Motor

1. Purpose-build design

The XINGLI drum motor has been specifically designed for belt conveyors

2. Totally enclosed

The motor, gearbox and bearings are totally enclosed and sealed inside a steel shell; therefore they are unlikely to fail due to harmful environmental conditions such as water, dust, grit chemicals, grease, oil, etc.

3. Space saving design

Because the drive unit and the bearings are mounted inside the motorized pulley shell, it takes up much less room than a conventional drive. No need for costly extras like chains, v-belts, couplings, bearings, support structure and special guarding.

4. Safety

The XINGLI drum motor is probably one of the safest drives available because the motor is completely enclosed and the external shafts are always stationary. The only moving external parts are the motorized pulley shell and bearing housings.

5 .Low purchasing and installation cost

The XINGLI drum motor is quite often less expensive than exposed drives because it has fewer parts. Therefore less conveyor design and parts purchasing costs. It is also much quicker and easier to install-certainly less than a quarter of the time taken to fit an exposed system.

6 .Low maintenance cost

The end user also benefits from the XINGLI drum motor, because it requires no maintenance other than the recommended oil change every 10,000 hours and oil seal change every 30,000 hours. In other words almost 5 years between oil changes based on 8-hour/day working week. Synthetic oil can be specified to extend the service range up to 30,000 hours.

7. Efficiency

The XINGLI drum motor usually has a much higher efficiency from electrical motor to shell(pulley face)than conventional drives, because it has fewer frictional losses, and therefore efficiencies of up to 94% can be achieved.

8.Fewer parts

A drum motor consists of the motorized pulley and two fixing brackets!

Exposed drives can require up to eight or more separate components, most of which have to be purchased

from different supplier or custom manufactured.

9.Low noise

Thanks to the totally sealed enclosure and high quality gears the motorized pulley runs almost

at a whisper-a very important fact in todays modern factory environments.

1. Are you manufacturer or trading company?

We are manufacturer verified by ALIBABA.

2. Where are you located? Is it convenient to visit you?

We are located in Huzhou . Traffic is very convenient.

3.

How can you

guarantee

quality?

3.1

We have complete working system and procedures and we follow them very strictly.

3.2 We have design and assemble staffs with rich experiences.

3. 3 We produce most of components our self . And easy to control their quality.

3. 4. We will do strict test running after the machine is finished.

4. Can you design according to our requirement?

Yes. we can . We can manufacturer according to your technical drawing , o r we can design according to your requirement. After you confirmed our design. We will start manufacturing.

5. Can you offer overseas technical support?

Yes. We can. But our quotation is not including this cost. If it is needed, the technical staff's salary/traffic charge/accommodation costs during the technical support should be on your account.

6 . Can I get sample?

Yes, sample orders welcomed

7 . Could I use my own LOGO or design for goods?

Yes, customized logo and design are available

8 . What will be the payment term?

T/T, L/C, Western Union, etc., it is flexible

9 . May I visit your factory?

Sure, welcome any time, we can also pick you up at airport and station, please let us kn ow