This machine function that to mixer the raw material,like corn flour,wheat flour,and mixer with the water and other additives.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

MEITENG

-

Voltage:

-

220/380V

-

Power:

-

45kw

-

Dimension(L*W*H):

-

26000*2000*2300mm

-

Weight:

-

3000 KG

-

Product name:

-

Commercial Industrial Long Cut Pasta Spaghetti Production Line

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Macaroni Pasta

-

Function:

-

pasta noodle making machine

-

Material:

-

Food Grade Stainless Steel

-

Usage:

-

Food Processing Industry

-

Capacity:

-

80-100kg/h

-

Feature:

-

Low Energy High Speed

-

Raw material:

-

rice or corn or other type wheatflour powder

-

MOQ:

-

1 Set

Quick Details

-

Production Capacity:

-

80-100KG/H

-

Type:

-

macaroni

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MEITENG

-

Voltage:

-

220/380V

-

Power:

-

45kw

-

Dimension(L*W*H):

-

26000*2000*2300mm

-

Weight:

-

3000 KG

-

Product name:

-

Commercial Industrial Long Cut Pasta Spaghetti Production Line

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Macaroni Pasta

-

Function:

-

pasta noodle making machine

-

Material:

-

Food Grade Stainless Steel

-

Usage:

-

Food Processing Industry

-

Capacity:

-

80-100kg/h

-

Feature:

-

Low Energy High Speed

-

Raw material:

-

rice or corn or other type wheatflour powder

-

MOQ:

-

1 Set

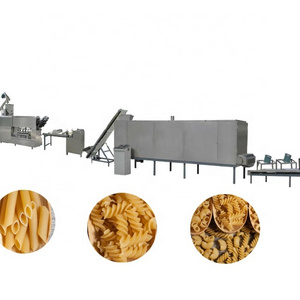

Automatic Italian Pasta Spaghetti Making Machine/Commercial Industrial Long Cut Pasta Spaghetti Production Line

adopts the flour ,corn starch , and potato starch as the raw material then forms a kind of leisure food after extruding ,slaking, forming,drying,frying and inflating. Our company has improved the production line performance by means of the marketing research and our own technology and makes the operator operate the equipment easily and make the craft more perfect.

Automatic india price electric mini making macaroni pasta machine

is indispensable production food equipment for everyone taking on the food profession.

1).

Automatic Italian Pasta Spaghetti Making Machine/Commercial Industrial Long Cut Pasta Spaghetti Production Line

adopts the semolina,wheat flour as the raw material.

2).Pasta was made to different shapes through the extruder by different molds

2. Flow chart: Mixing system---Extrusion system----Cutting system---Drying system---Frying system---Flavoring System --Packing system

3.Capacity and power: find attached below form.

4.Voltage: Three phases 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries.

5.Material: All made by stainless steel 201

Technical Parameter:

|

Model

|

Installed power

|

Real power

|

Output

|

Dimension

|

|

MT100

|

70KW

|

40KW

|

80-120kg

|

22000*1200*2200mm

|

|

MT120

|

90KW

|

60KW

|

100-150kg

|

25000*1500*2200mm

|

|

MT130

|

110kw

|

90kw

|

150-200kg

|

30000*3500*4300mm

|

Mixer machine

Single Screw Extruder Machine

Single screw extruder machine is used to do differernt puff and fried snack also with different screw or motor or gear box,it can do macaroni snack and other special products.

Dryer machine

this machine function that to bake differertn snack ,for example puff snack ,rice ,chips ecen animal food,it can with different length and layer only desigh depend on what kind of product .

Conveyor and cooling machine

Multi-layer cooling machine can fully cool the product, and the multi-layer structure can accommodate larger output.

Our products are sold very well throughout China and are also introduced to Southeast Asia, East Europe, Africa and other regions.

Our market share is increasing each year.

Paking of Automatic Italian Pasta Spaghetti Making Machine/Commercial Industrial Long Cut Pasta Spaghetti Production Line :

Packing Details : Packing, we will use double film to protect product.

Delivery Details : 3-30 days after order of macaroni production line.

Our usually packing is flim,if the customer need the wooden box is ok. We can customize according to customer needs

2). Free consultation service before, during, and after sales;

3). Free project planning and design services;

4). Free debugging of equipment until everything is functional;

5). Free management of equipments long distance shipping;

6). Free training of equipment maintenance and operating personally;

7). Free new production techniques and formulas;

8). Provide 1 year complete warranty and life-time maintenance service;

Design

we can according to client's factory to design put project design

Test Machine

when client visit our factory we will test machine for customer

Installation

After we cooperate ,we offer oversea serivice