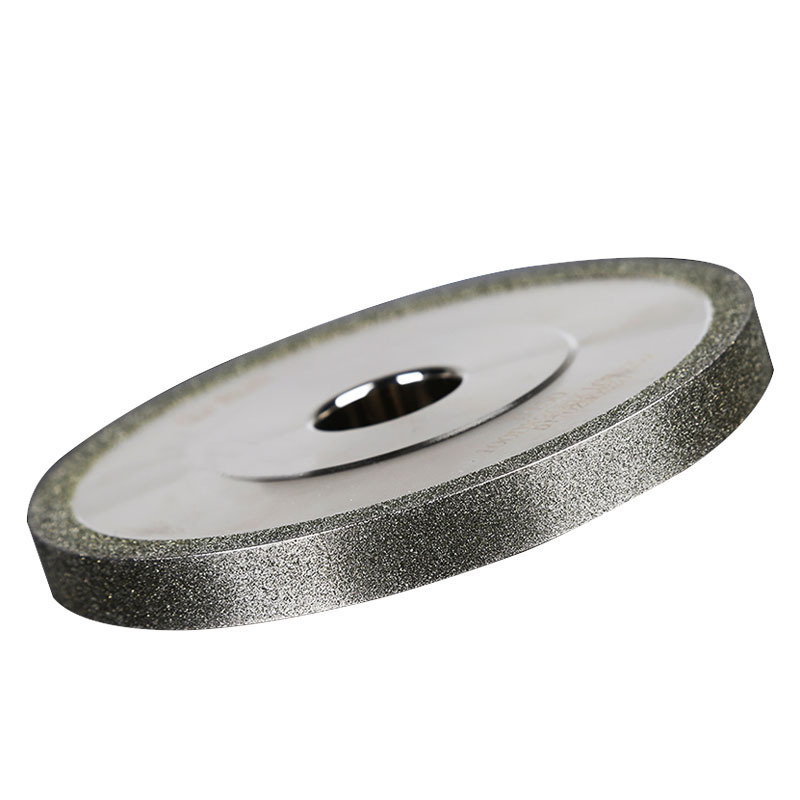

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Electroplated Grinding Wheel

-

Application:

-

Grinding

-

Color:

-

Black

-

Material:

-

SDC

-

Shape:

-

Flat-Shaped

-

Grit:

-

40#~600#/customizable

-

diameter:

-

100mm/customizable

-

Thickness:

-

20mm/customizable

Quick Details

-

Type:

-

grinding wheel

-

Place of Origin:

-

Shandong, China

-

Brand name:

-

Xintaili

-

Product name:

-

Electroplated Grinding Wheel

-

Application:

-

Grinding

-

Color:

-

Black

-

Material:

-

SDC

-

Shape:

-

Flat-Shaped

-

Grit:

-

40#~600#/customizable

-

diameter:

-

100mm/customizable

-

Thickness:

-

20mm/customizable

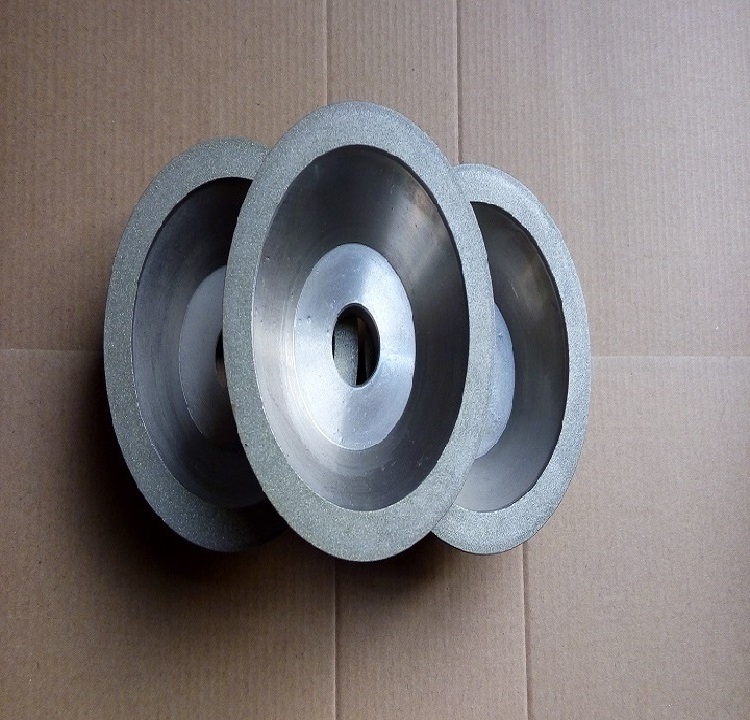

High efficiency electroplated 100mm grit abrasive cbn diamond bowl grinding wheel sharpening stone

|

Product Name |

High Quality Electroplated Diamond Grinding Wheel |

|||||

|

Application |

Mainly used for grinding&cutting hard and brittle alloy,non-metal materials. Such as hard alloy, ceramics, agate, optical glass, semiconductor materials and wear-resistant cast iron, stone, spring steel, tool steel, bearing steel, etc. |

|||||

|

Bond Material |

Metal, Resin etc. |

Blade Color |

Natural or Customized |

|||

|

Brand |

Dr.S or OEM |

Payment |

T/T, Western Union, Paypal, etc. |

|||

|

Blade Material |

Diamond /CBN |

Package |

Carton box or Customized |

|||

|

Usage |

Dry & Wet |

Delivery |

7-12 days after down payment |

|||

|

Specification

(Can be customized) |

Brand Type |

Diameter |

Height |

|||

|

Metal bond |

30 - 600mm |

0.15 - 150 mm |

||||

|

Resin bond |

30 - 500 mm |

5 - 150 mm |

||||

|

Vitrified bond |

30 - 500 mm |

5 - 150 mm |

||||

|

Electroplated |

Customized |

|||||

|

Shape code |

1A1, 1V1, 1EE1, 1FF1, 3A1, 11A2, 6A9, 14A1,14A1R,11V9, 11C9, 4A2, 6A1,6A2, 12A2, 9A3, 1F1,12V2, 1L1, 14EE1, 4B1, 14E1, 4A2P, 11B2, 6A2T, 11V2, 9A1, 1A1R, 1F1, 1A8, 9A1, 9A1B,3K1, 1A1W, 4V2, 1A3, 1A2T,1A2, 12C9 14E6Q, etc. |

|||||

|

Advantages |

1. High hardness, high strength, strong abrasive 2. Self sharp, small working heat, not easy to plug

3. Long life span and stable performance

5. Safe package and fast delivery 6. Professional&excellent service |

|||||

|

Production Technology |

Hot Pressed & Cold Pressed , Brazed, Laser Welded |

|||||

|

MOQ |

5pcs of each specification,Total need more than 10pcs |

|||||

|

Main Market |

USA, Canada, Germany, Italy, Portugal, Poland, Russia, Brazil, Chile, Australia, UAE, South Africa etc. |

|||||

Advantages of electroplated diamond grinding wheel

1.electroplated process is simple, less investment, convenient manufacture;

2.without dressing, easy to use;

3.monolayer structure determines the it can achieve very high working speed, currently , has been as high as 250 ~ 300m / S;

4.although only a monolayer diamond, but there is still enough life time;

5.for the high precision request rolling wheel, electroplated is the only manufacture method.

Because of these advantages, During high speed, ultra high speed grinding process, electroplated occupies the undisputed dominant position.

Application range of electroplated diamond tools

2.1 machinery processing industry

Electroplated diamond roller has been successfully applied to the grinding wheel or directly to the work piece grinding, and widely used in the processing of crankshaft, bearing, hydraulic valve, etc..

Electroplated diamond manual assorted file or machine with a file, and various shapes of diamond grinding wheel is widely used in machining grinding, made of hard alloy or quenching hard steel mold and shape of work piece surface and the inner hole.

Electroplated diamond reamer has become the hydraulic equipment and sewing machine parts reaming tool. It has the advantages of high precision, high efficiency, durability, etc..

2.2 electrical and electronic industry

Electroplated diamond internal and external cutting blade is the best tool for cutting hard brittle semiconductor and other precious materials. Has the characteristics of high efficiency, narrow cut seam, less material loss, etc..

Electrical and electric equipment commonly used graphite and carbon materials, with hard and brittle nature of the electroplated diamond grinding and planed stone ink block; available plating of diamond saw blade; available electroplated grinding wheel forming grinding.

2.3 glass industry

Plating diamond cutting tool can be directly in the optical glass plate to take out various specifications of optical instrument lens round billet.

Electroplated diamond grinding wheel, reamer, drill, milling, drilling, can be carried out in the ordinary flat glass on the hole.

2.4 arts and crafts industry

Electroplated diamond grinding head, bite to carve and all kinds of precious stones, jade, ceramics and other industrial art flower mill.

Electroplated diamond nail file as one of the tools for people to complete the modification, grinding nails.

Diamond grinding wheel is used for rubber soles.