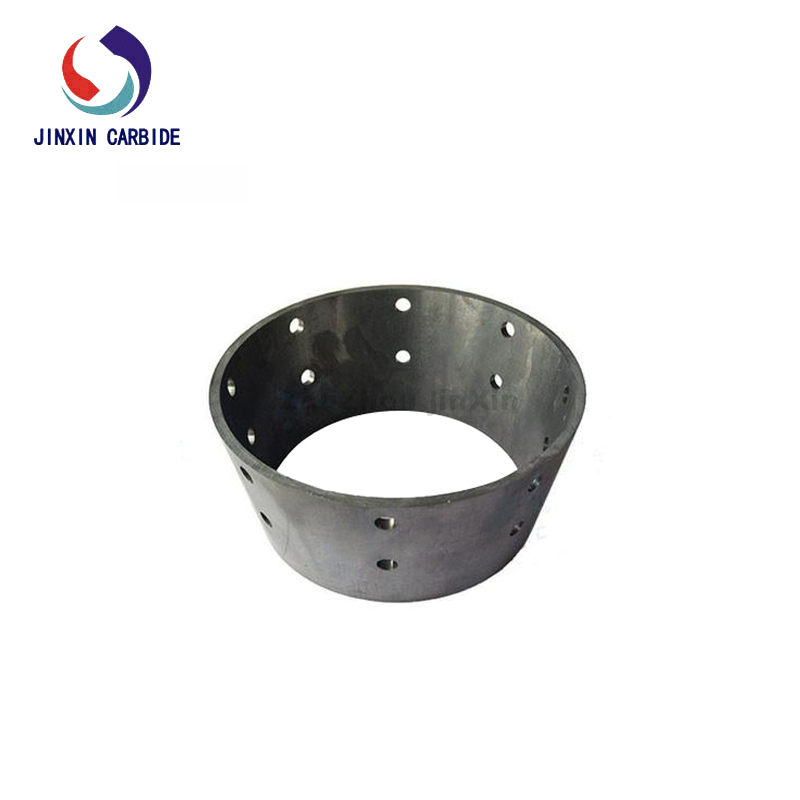

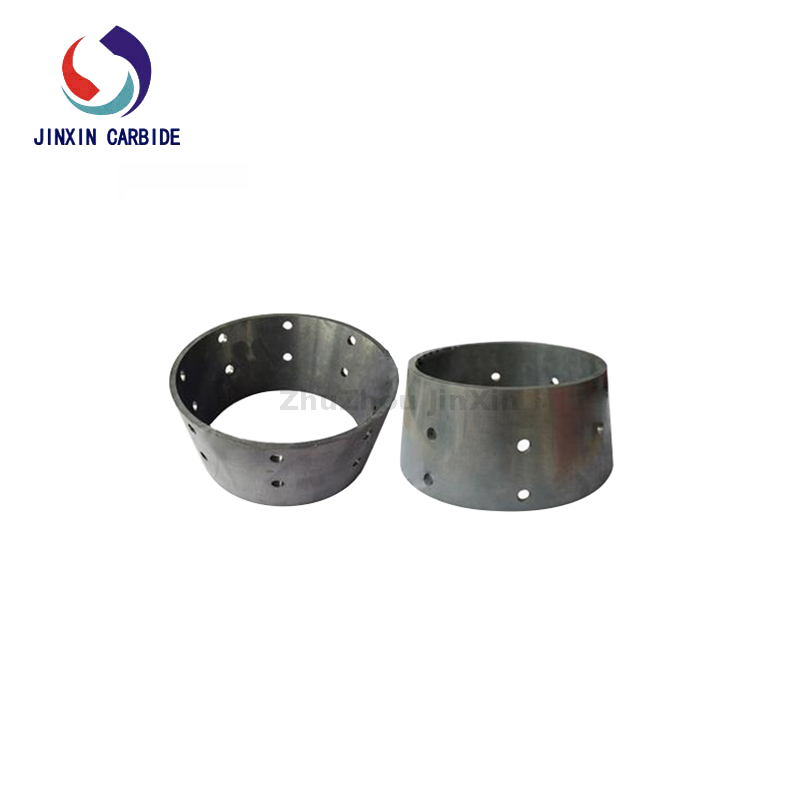

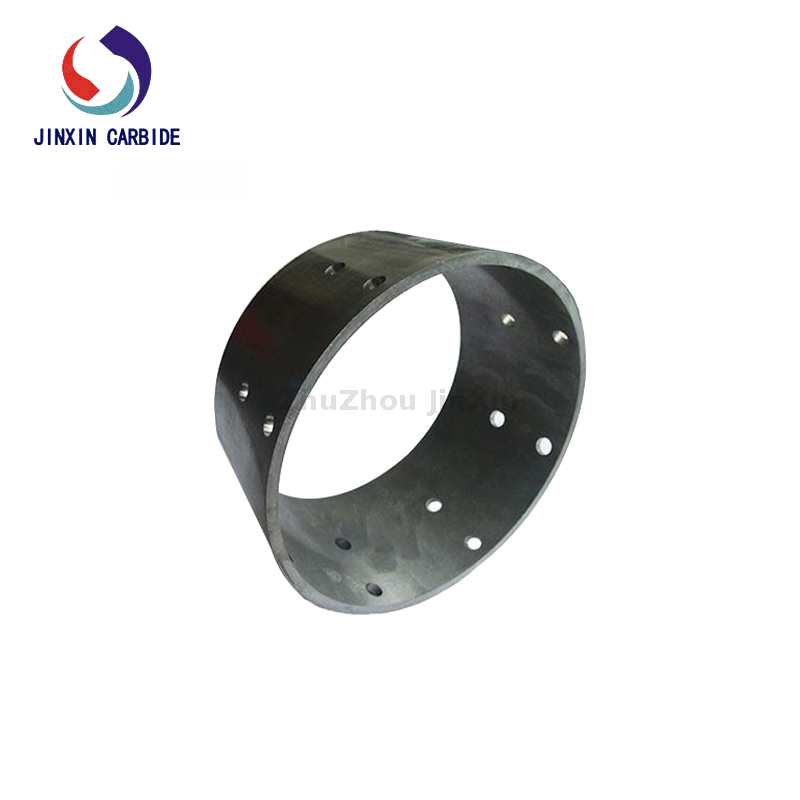

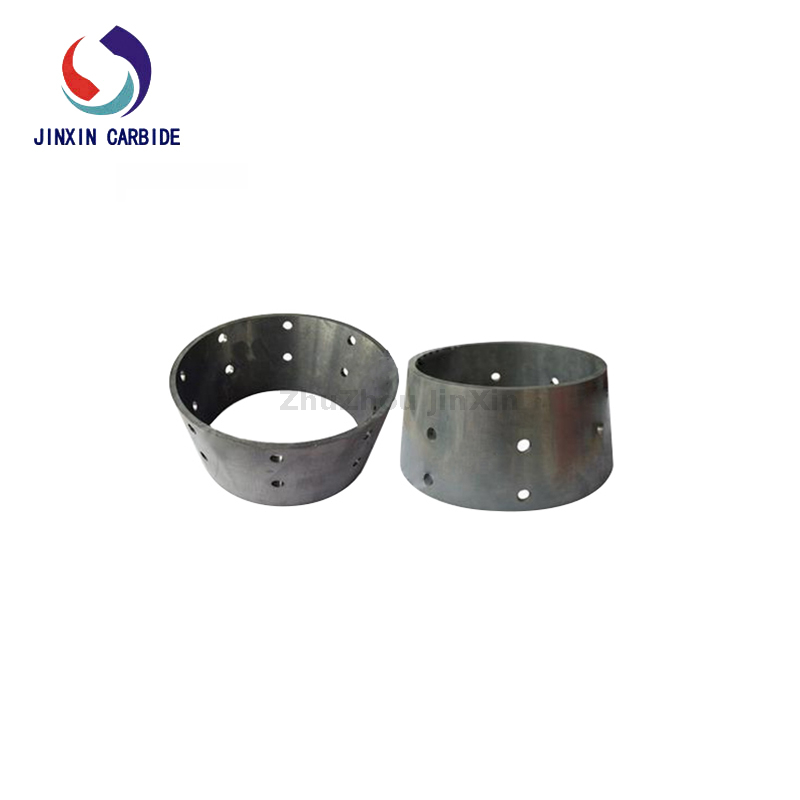

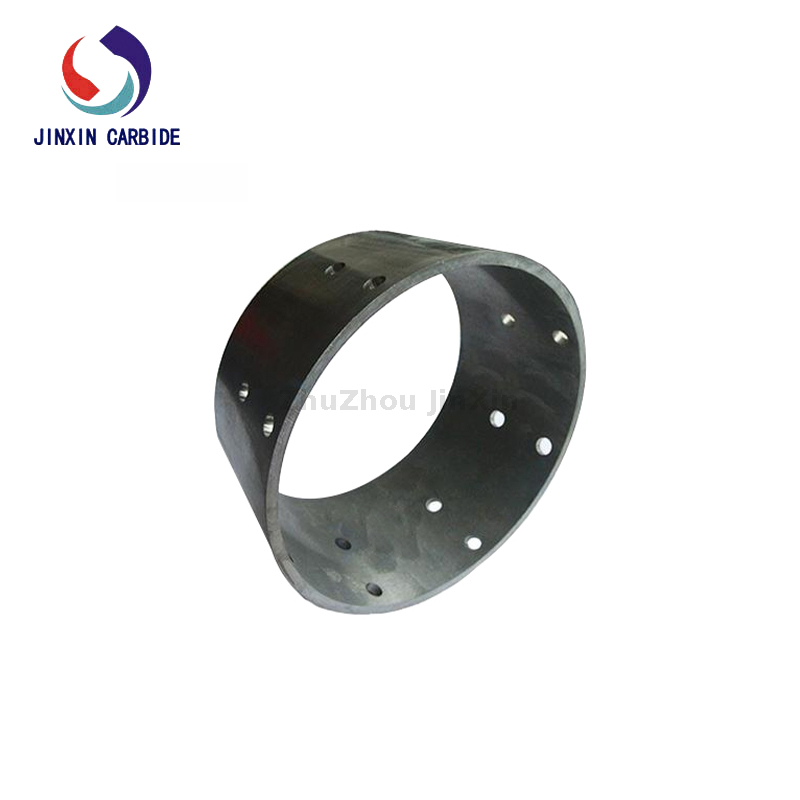

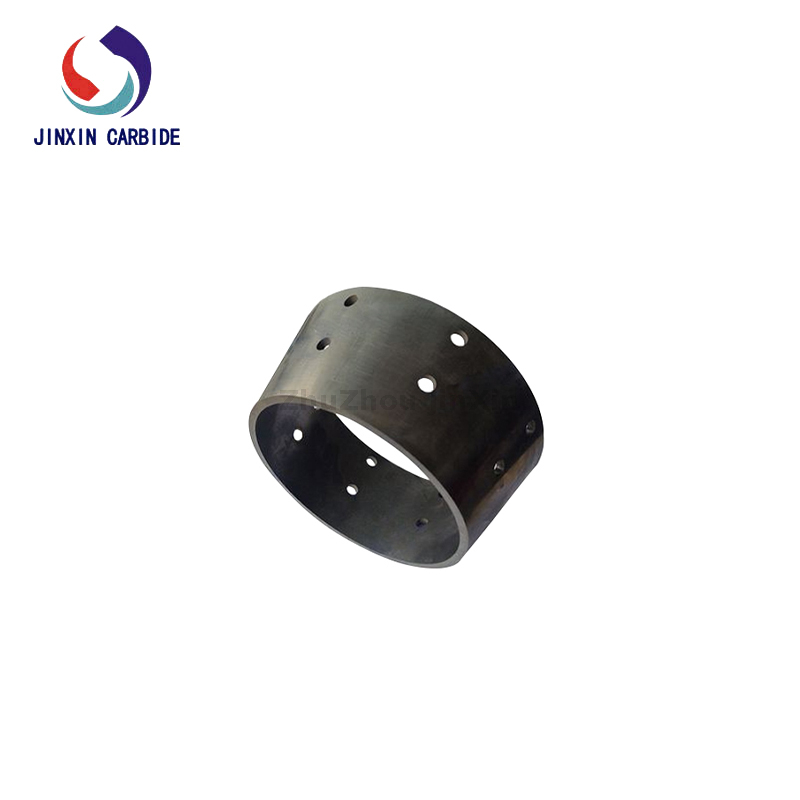

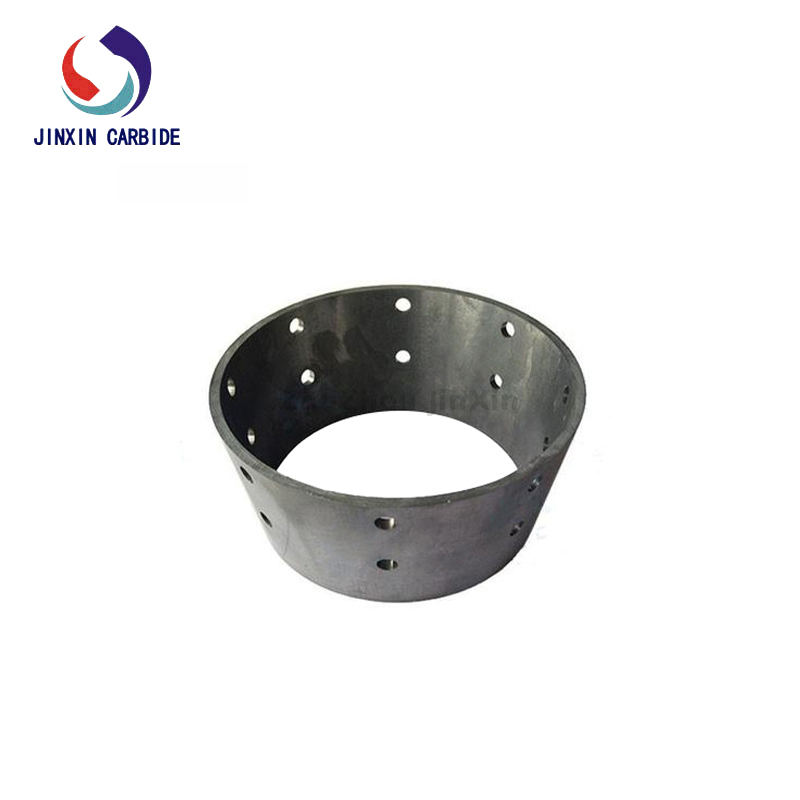

Carbide Cone Round Uses:

It Used in cone sand mills, suitable for ultra-fine grinding of large quantities of medium and high viscosity products. The volume

of the grinding area and grinding can be adjusted to achieve the best grinding and dispersion effects.

- Product Details

- {{item.text}}

Quick Details

-

shape:

-

Special-shaped

Quick Details

-

Weight (KG):

-

1

-

Place of Origin:

-

China

-

Brand Name:

-

jx

-

shape:

-

Special-shaped

Tungsten Carbide Cone Round

.

Working Principle

:

The dispersing grinder consists of a double-wall grinding cylinder grinding mill, a suction pump, a disturbance device, a

dispersing disc and a screen. Its principle is mainly to utilize the material circulation formed in a closed container, so that

the material circulates continuously and is homogenized and refined after impact and grinding with the high-speed grinding medium

in the grinding cylinder. The material circulation is based on the high-speed rotation of the pump wheel and the dispersion disc,

which causes the material to form a pressure field in the container. The material is sucked in from the suction pump, separated

from the grinding media through the screen, and thrown out by the dispersion disc. At the same time, a material is generated in

the container. The eddy current effect can stir, impact and disperse the materials again. It is a dispersing and grinding

equipment integrating dispersing and grinding.

dispersing disc and a screen. Its principle is mainly to utilize the material circulation formed in a closed container, so that

the material circulates continuously and is homogenized and refined after impact and grinding with the high-speed grinding medium

in the grinding cylinder. The material circulation is based on the high-speed rotation of the pump wheel and the dispersion disc,

which causes the material to form a pressure field in the container. The material is sucked in from the suction pump, separated

from the grinding media through the screen, and thrown out by the dispersion disc. At the same time, a material is generated in

the container. The eddy current effect can stir, impact and disperse the materials again. It is a dispersing and grinding

equipment integrating dispersing and grinding.

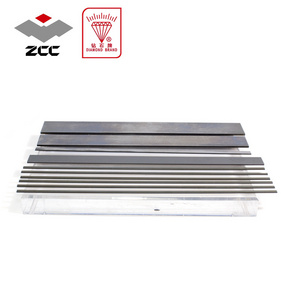

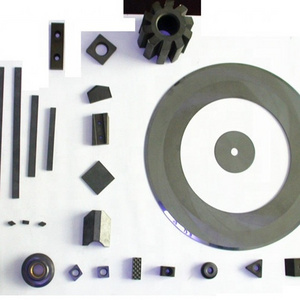

Tungsten carbide can be pressed and formed into customized shapes, can be grinded with precision, and can be welded with or

grafted to other metals. Various types and grades of carbide can be designed as required for use in application intended,

including chemical industry, oil & gas and marine as mining and cutting tools, mould and die, wear parts, etc. Tungsten carbide is

widely used in industrial machinery, wear resistant tools and anti-corrosion.

Customized service is welcomed.

grafted to other metals. Various types and grades of carbide can be designed as required for use in application intended,

including chemical industry, oil & gas and marine as mining and cutting tools, mould and die, wear parts, etc. Tungsten carbide is

widely used in industrial machinery, wear resistant tools and anti-corrosion.

Customized service is welcomed.

Hot Searches