- Product Details

- {{item.text}}

Quick Details

-

Power:

-

7.5-55KW

-

Weight:

-

2400 KG

-

Dimension(L*W*H):

-

8500*2100*265OMM

-

Product name:

-

Dog Food Making Machine

-

Raw material:

-

Corn Flour

-

Type:

-

Single Screw

-

Function:

-

Producing Animal Feeds Pellets

-

Name:

-

Fish Feed Extruder machine

-

Product:

-

Dog Cat Pig Bird

-

Usage:

-

Pet Cat Dog Feed Extruder

-

Conditioner power:

-

1.5kw- 15kw

-

Processing Types:

-

Twin Screw Extrusion

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

tianruomachinery

-

Voltage:

-

220/380/410/440/110

-

Power:

-

7.5-55KW

-

Weight:

-

2400 KG

-

Dimension(L*W*H):

-

8500*2100*265OMM

-

Product name:

-

Dog Food Making Machine

-

Raw material:

-

Corn Flour

-

Type:

-

Single Screw

-

Function:

-

Producing Animal Feeds Pellets

-

Name:

-

Fish Feed Extruder machine

-

Product:

-

Dog Cat Pig Bird

-

Usage:

-

Pet Cat Dog Feed Extruder

-

Conditioner power:

-

1.5kw- 15kw

-

Processing Types:

-

Twin Screw Extrusion

Products Description

Complete equipment Floating

Fish feed pet food production line

The fish feed pet food production line is increasing with the variety of pets, and various pets are different from adults and children. The requirements for pet food are also increasing. Tianruo Machinery Co., Ltd. has developed a variety of pet food production lines according to the market demand. According to the different output, the production line also has a variety of configurations to meet the needs of different customers. The production equipment can adjust the raw materials, temperature, moisture and other process parameters to make the product have the characteristics of novel shape, unique taste, rich nutrition, and delicate tissue, which is suitable for different pet tastes. The production line is widely applicable to the production of dog, cat, fish, shrimp, fox and various pet feeds, and is an ideal choice for different manufacturers.

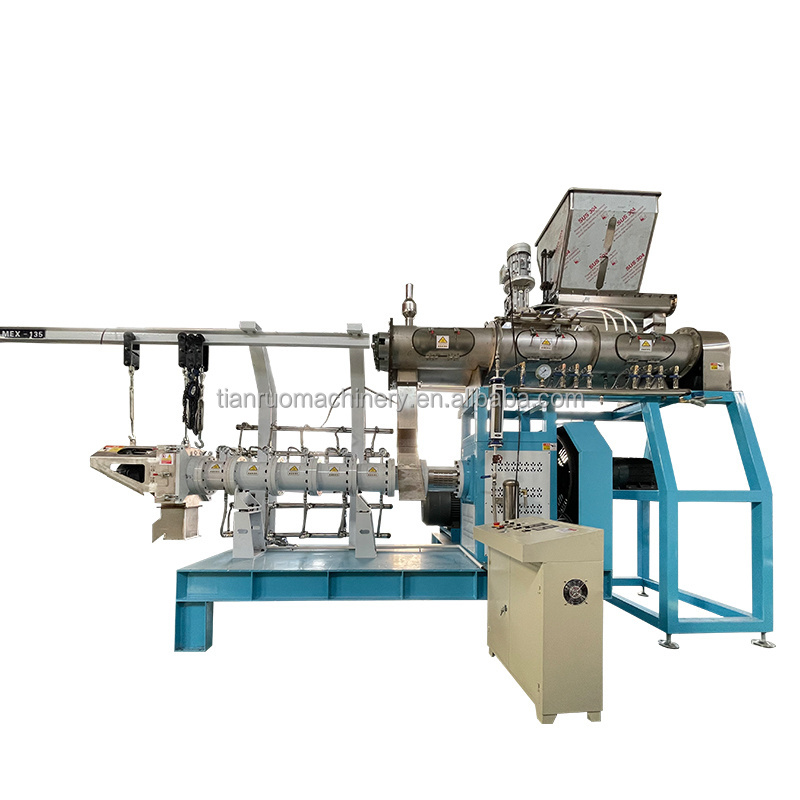

1. DSP Series Wet Type Single Screw Extruder

Wet Type screw feed extruder is very suitable for aquatic pet feed. The energy consumption of twin-screw is lower than that of single screw by kneading and rubbing each other. In this way, the material can be kneaded and ripened more fully, the overall ripening degree can reach more than 95%, the stability of the product in water can be maintained at more than 24h, and the surface finish and particle uniformity of the particles are also better. After the extruded feed is fully cooked, the animals will not only taste good, but also have high digestibility and easy to absorb nutrients.

|

Model

|

Capacity

|

Power

|

Cutter Power

|

Dimension

|

|

DSP-60

|

100-150 kg/h

|

15 kw

|

0.4 kw

|

1.45*0.95*1.5 m

|

|

DSP-70

|

180-250 kg/h

|

18.5 kw

|

0.4 kw

|

1.6*1.4*1.45m

|

|

DSP-80

|

300-350 kg/h

|

22 kw

|

0.6 kw

|

1.87*1.4*1.5m

|

|

DSP-100

|

400-450 kg/h

|

37 kw

|

0.6 kw

|

1.7*2.3*1.4m

|

|

DSP-120

|

500-700 kg/h

|

55kw

|

1.5kw

|

2.2*2.9*1.2m

|

|

DSP-135

|

800-1000 kg/h

|

75kw

|

2.2kw

|

2.25*3.1*1.37m

|

|

DSP-160

|

1200-1500 kg/h

|

90kw

|

2.2kw

|

2.2*3.15*1.37m

|

|

DSP-200

|

1800-2000 kg/h

|

132kw

|

3.0kw

|

2.3*3.45*1.65m

|

2. DGP Series Dry Type Fish Feed Extruder

has the same application with wet extrusion plant (manufacturing fish feed in commercial aquaculture, providing balanced nutrition for farmed fish.)but with smller production capacity(180-200kg/h). therefore it is mostly favored by owners of small scale fish farms tha have lower requiment on the prcessing technique technique and output.

|

Model

|

Capacity

|

Power

|

Cutter Power

|

Dimension

|

|

DGP-40

|

40-50kg/h

|

5.5kw

|

0.4kw

|

1.25*1.03*1.3m

|

|

DGP-50

|

80-100kg/h

|

11kw

|

0.4kw

|

1.28*1.03*1.2m

|

|

DGP-60

|

100-150 kg/h

|

15 kw

|

0.4 kw

|

1.45*0.95*1.5m

|

|

DGP-70

|

180-250 kg/h

|

18.5 kw

|

0.4 kw

|

1.6*1.4*1.45m

|

|

DGP-80

|

300-350 kg/h

|

22 kw

|

0.6 kw

|

1.87*1.4*1.5m

|

|

DGP-100

|

400-450 kg/h

|

37 kw

|

0.6 kw

|

1.7*2.3*1.4m

|

|

DGP-120

|

500-700 kg/h

|

55kw

|

1.5kw

|

2.2*2.9*1.2m

|

|

DGP-135

|

800-1000 kg/h

|

75kw

|

2.2kw

|

2.25*3.1*1.37m

|

|

DGP-160

|

1200-1500 kg/h

|

90kw

|

2.2kw

|

2.2*3.15*1.37m

|

|

DGP-200

|

1800-2000 kg/h

|

132kw

|

3.0kw

|

2.3*3.45*1.65m

|

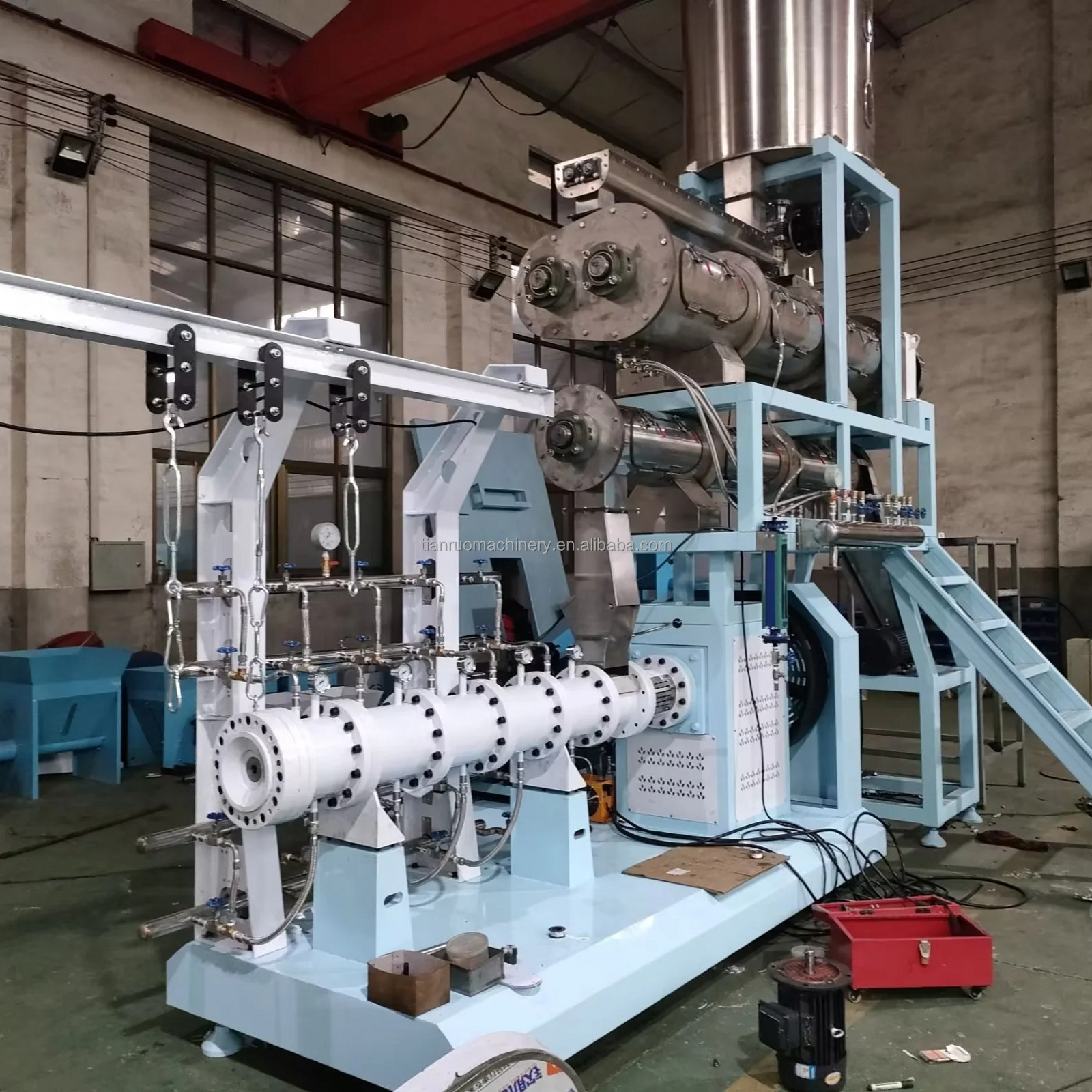

3. Twin Screw Wet Type Extruder Machine with steam

super automation control and high production efficiency, it's the best choice for medium and big sized feed mill and breeding farms. This processing line can produce various kinds of pellets for different varities of fishes inclusing halibut pellets, catfish pellets, catcarp pellet, trout pellets, hemp pellets, csl pellets, etc.

|

Model

|

Capacity

|

Power

|

Conditionor

|

Cutter Power

|

Dimension

|

|

WT-75-B

|

400-500kg/h

|

22 kw

|

1.5 kw

|

0.75 kw

|

1.25*1.03*1.3 m

|

|

WT-85-B

|

600-650kg/h

|

30kw

|

2 kw

|

1.1 kw

|

1.28*1.03*1.2 m

|

|

WT-90-B

|

700-850kg/h

|

37kw

|

3 kw

|

1.1 kw

|

1.45*0.95*1.5 m

|

|

WT-100-B

|

900-1000kg/h

|

55 kw

|

3 kw

|

1.5 kw

|

1.6*1.4*1.45 m

|

|

WT-135-B

|

1200-1500kg/h

|

75 kw

|

5.5 kw

|

2.2 kw

|

1.87*1.4*1.5 m

|

|

WT-145-B

|

2000-3000kg/h

|

90 kw

|

7.5 kw

|

2.2 kw

|

1.7*2.3*1.4 m

|

Related Product

Crusher Machine.

Crushing material into Power.size can adjustable, have screen inside

high-efficiency multi-function pulverizer, the size after crushing can be adjusted according to customer requirements.

Mixer Machine

Feed mixer machine is usually used to fully and evenly mix the crushed feed raw materials together. Like wheat flour, corn flour, soybean flour, bone meal, soybean oil, etc.

Dryer Machine

Vertical feed pellet dryer is a machine that is designed to remove moisture from feed pellets, which are widely used to fish feed pellets,

Horizontal Mixer Machine

It can be used for food, pharmaceutical industry powder raw materials and a small amount of liquid or dry powder raw materials mixing, such as pastry stuffing or mix dry powder, etc.

Octagonal Seasoning Machine

It is very popular in food processing industry. It's mainly used in flavoring and mixing all kinds of food, such as chips, french fries, fruit brittle, fried food, puffed food, snack food, leisure food, fruit chips, potato chips etc.

Drum Flavoring Machine

By the turning of the tumbling box, it can coat the products with even layer of the coating flour.Increase the quantity of the flour on the products surface.It causes the obvious scaly food surface

Mesh-belt Type Fish Feed Dryer

it is applied in the construction industry, food industry, chemical industry, ceramic industry, paper products, bamboo and wood products, flower and grass industry, rubber industry, and food puffing industry.

Packing Machine

Packing Material : Organic fertilizer, feed, river sand, grain, chemical industry, metallurgy, refractory materials, etc.

Counter Flow Cooler Machine

The feed cooler/dryer is suitable for cooling various kinds of pellets such as pelleted feed, expanded feeds, extruded feeds and flake feeds etc.

Conveyor

The conveying speed can be controlled bu frequency inverter to follow the feeding speed of extruder

length can be customized ,

Poultry Animal Feed Pellet Machine

1.animal feed/food pellet making machine can be used for processing livestock, poultry and aquatic feed pellets,such as dog pellets and chicken pellets and so on.

2.it is specially suitable for medium feed factory, breed farm It has the better raw material versatility, which can be suitable for pelletizing many kinds of raw material.

3.this manufacturing plant for animal feed has the features of low energy consumption and high production efficiency for larger profits.

4.We provide free charge of installation, and training, factory designing, and timely after-sale service

Electric motor pellet machine

Machine with control panel

Diesel engine pellet machine

|

Model

|

Capacity

|

Power

|

Weight

|

Pellet size

|

Dimension

|

|

LKL-125

|

80-100kg/h

|

3 kw

|

95kg

|

2.5-10mm

|

110*35*70cm

|

|

LKL-150

|

120-150kg/h

|

4.5 kw

|

100kg

|

2.5-10mm

|

115*35*80cm

|

|

LKL-210

|

200-300kg/h

|

7.5kw

|

280kg

|

2.5-10mm

|

115*45*95cm

|

|

LKL-230

|

400-500kg/h

|

11kw

|

320kg

|

2.5-10mm

|

115*45*95cm

|

|

LKL-260

|

500-600kg/h

|

15kw

|

380 kg

|

2.5-10mm

|

130*53* 105cm

|

|

LKL-300

|

600-800kg/h

|

22kw

|

600 kg

|

2.5-10mm

|

160*67* 145cm

|

|

LKL-360

|

900-1000kg/h

|

30kw

|

800kg

|

2.5-10mm

|

160*67*145cm

|

|

LKL-400

|

1000-1500kg/h

|

30kw

|

1000kg

|

2.5-10mm

|

152*60*115cm

|

Pellet machine with 2 Roller

Pellet machine with 3 Roller

Pellet machine with 4 Roller

Animal Feed Production Line

Hot Searches