- Product Details

- {{item.text}}

Quick Details

-

Roll Ratio(Front/Back):

-

1:1.27

-

Cooling Mode:

-

water cooling

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Guangyue/OEM

-

Voltage:

-

Customer Request

-

Dimension(L*W*H):

-

2080*1000*2130 Mm

-

Year:

-

2024

-

Power (kW):

-

45

-

Weight (KG):

-

7800 KG

-

Product name:

-

Open Mixing Mill

-

Roller material:

-

cast iron steel(HS75)

-

pedestal:

-

cast or weld

-

gear reducer:

-

planetary,hardened tooth

-

Bush:

-

Ball Bearing Bush

Quick Details

-

Diameter of Roll(mm):

-

450 mm

-

Rotation Speed of Front Roll(rpm):

-

10 - 100 rpm

-

Length of Roll(mm):

-

1200 mm

-

Roll Ratio(Front/Back):

-

1:1.27

-

Cooling Mode:

-

water cooling

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Guangyue/OEM

-

Voltage:

-

Customer Request

-

Dimension(L*W*H):

-

2080*1000*2130 Mm

-

Year:

-

2024

-

Power (kW):

-

45

-

Weight (KG):

-

7800 KG

-

Product name:

-

Open Mixing Mill

-

Roller material:

-

cast iron steel(HS75)

-

pedestal:

-

cast or weld

-

gear reducer:

-

planetary,hardened tooth

-

Bush:

-

Ball Bearing Bush

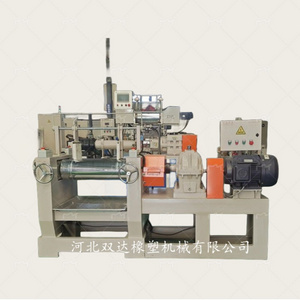

Two Roll Open Mixing Mill For Rubber & Plastic Rubber-Mixing-Mill-Indian Price Natural Rubber Xk450 Two Roll Open Mixing Mill

1. General Advantage :

1.1Good Process applicability

1.2Save energy

1.3Clean Environment

1.4High efficiency

1.5High quality

2 . Application

This machine is mainly used to plastic,hot mill and mixing mill of natural and synthetic rubber for rubber product factory .

3. Feature and structure :

3.1 This machine is consist of welding base ,frame , roll pitch devices ,transmission gearreducer ,motor ,electronic cabinet and emergence devices security protection devices and the other components .

3.2 The roller is made of general chilled iron , the roller surface and neck have high hardness and wear resistance through grind process .

The inner hold of roller wall thickness error will be decrease provide coefficient of heat conductivity ,heat uniform through grinder process .

The roller inner hold be connected heating and cooling devices . it is adjustment the roller temperature accesses steam and cooling water .

3.3 Pitch devices is consist of "T",adjustment handle, manual adjustment . Easy frame , convenient operation ,long life ,quick reaction and the other characteristic .

3.4 The machine is made of chilling cast iron , integral type structure base , easy install

3.5 The emergence devices used exchange transposition braking, please pull the over shaft stem when happened emergence ,it is stop operation .

4.Techinque parameter:

|

|

XK-400 |

XK-450 |

XK-560 |

|

Working diameter(mm) |

400 |

450 |

560/510 |

|

Woking length of rollls |

1000 |

1200 |

1530 |

|

Frontrollsurfacespeed(m/min) |

18.65 |

24.26 |

27.72 |

|

Friction ratio |

1:1.27 |

1:1.27 |

1:1.2 |

|

Max .nip(mm) |

10 |

15 |

15 |

|

Capacity per.batch(kg) |

18~35 |

25~50 |

35~50 |

|

Motor power(kw) |

37 |

55 |

90 |

|

Overall dimension: length×Width×Height(mm) |

4350×1850×1785 |

5200×2380×1840 |

5845×2284×1978 |