- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

21

-

Weight (KG):

-

2700

-

Product name:

-

sheet metal sanding deburring polishing machine

-

Function:

-

Removal of burrs, edge chamfer

-

Application material:

-

stainless steel, iron, copper, alloy, coated sheet

-

Max processing height:

-

60mm

-

Fixed mode:

-

Press roll+Magnetic adsorption + negative pressure adsorption

-

Advantage:

-

Polishing Finishing

-

Max processing width:

-

1000 mm

-

Power Supply:

-

380V/50Hz AC

-

Sand belt width:

-

1020 mm

-

Rollers number:

-

4

Quick Details

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Honry

-

Marketing Type:

-

New Product 2024

-

Power (kW):

-

21

-

Weight (KG):

-

2700

-

Product name:

-

sheet metal sanding deburring polishing machine

-

Function:

-

Removal of burrs, edge chamfer

-

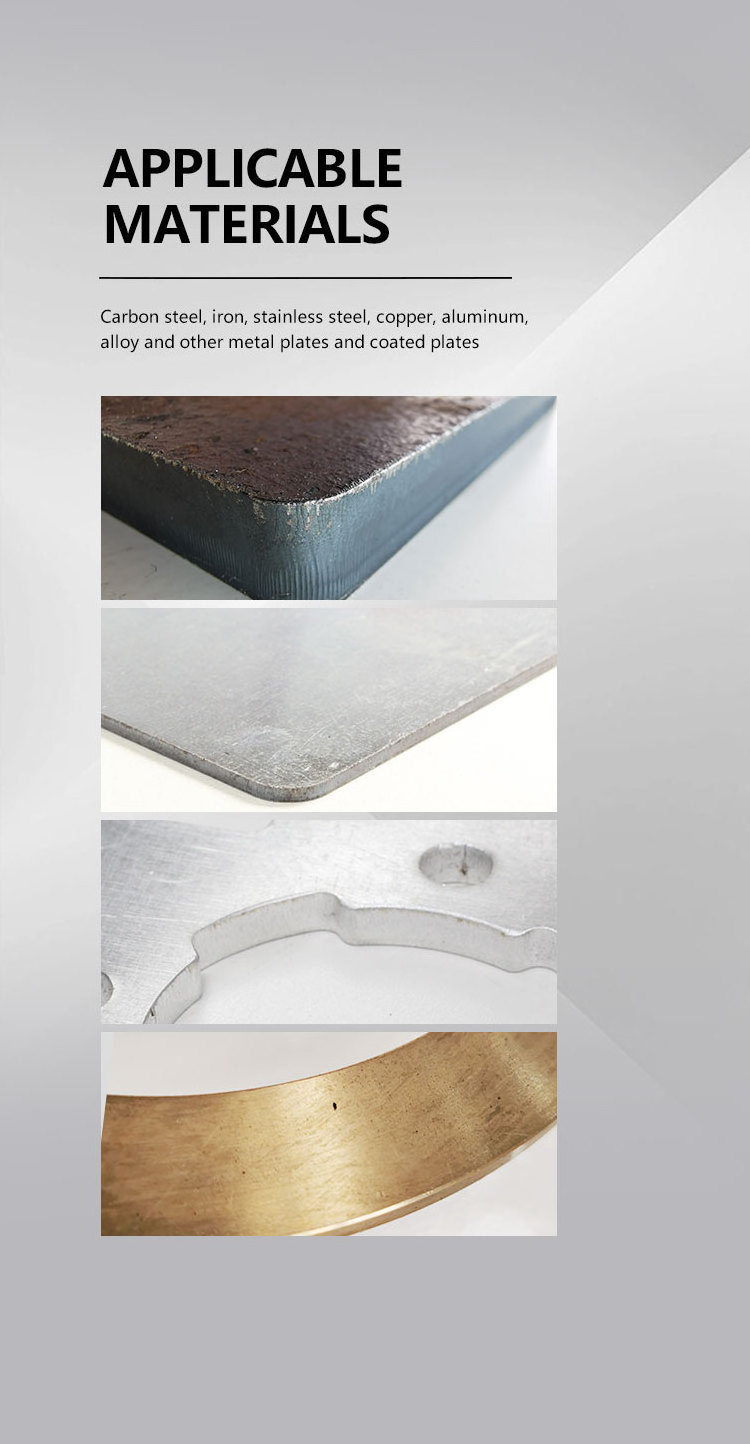

Application material:

-

stainless steel, iron, copper, alloy, coated sheet

-

Max processing height:

-

60mm

-

Fixed mode:

-

Press roll+Magnetic adsorption + negative pressure adsorption

-

Advantage:

-

Polishing Finishing

-

Max processing width:

-

1000 mm

-

Power Supply:

-

380V/50Hz AC

-

Sand belt width:

-

1020 mm

-

Rollers number:

-

4

Product Description

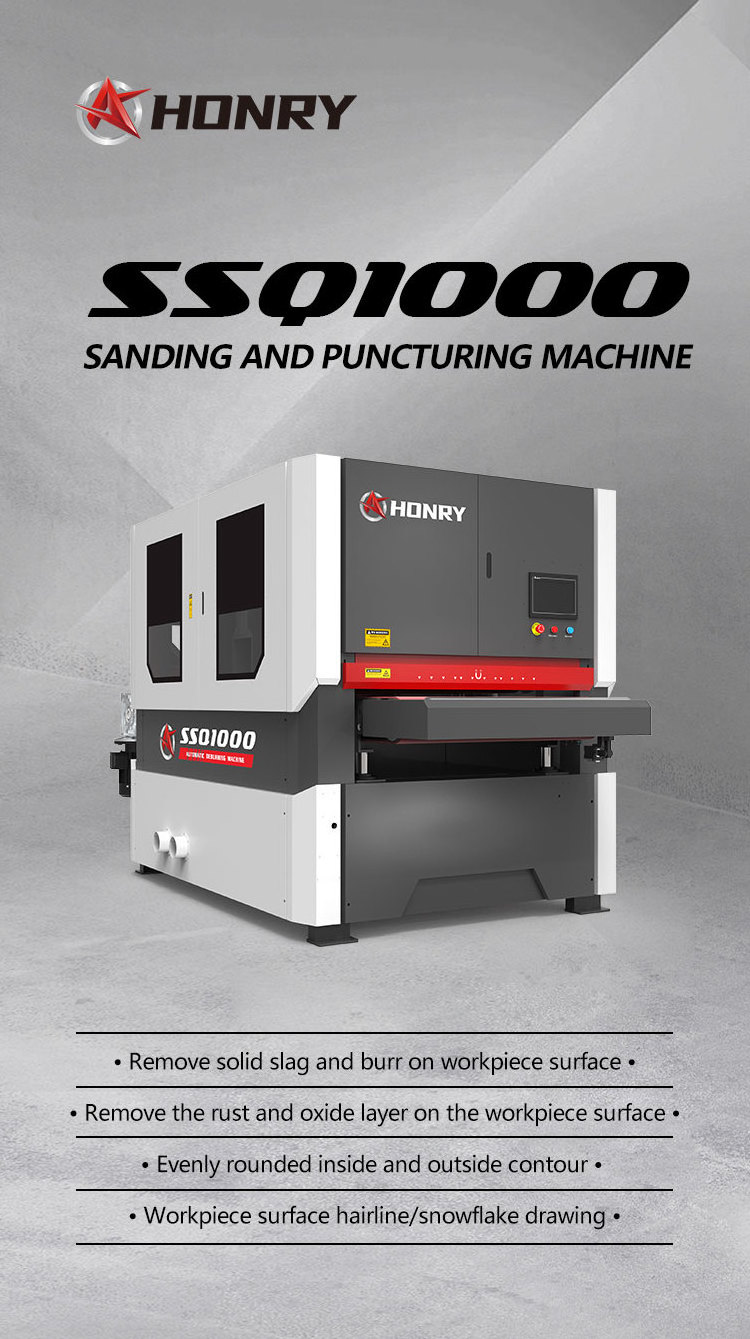

HONRY FLAT METAL DEBURRING MACHINE

Hongrui

is a brand specialized in the production of automatic metal deburring machine owned by

Tianjin Yicaijinyuan CNC Equipment Co., Ltd

. Brand line products include:

*

QC916, QC930, QC1325

;

SS1000, R-R1000, SM1000R-R

;

SQ1000, SSQ1000, SSQ1300

|

MODEL

|

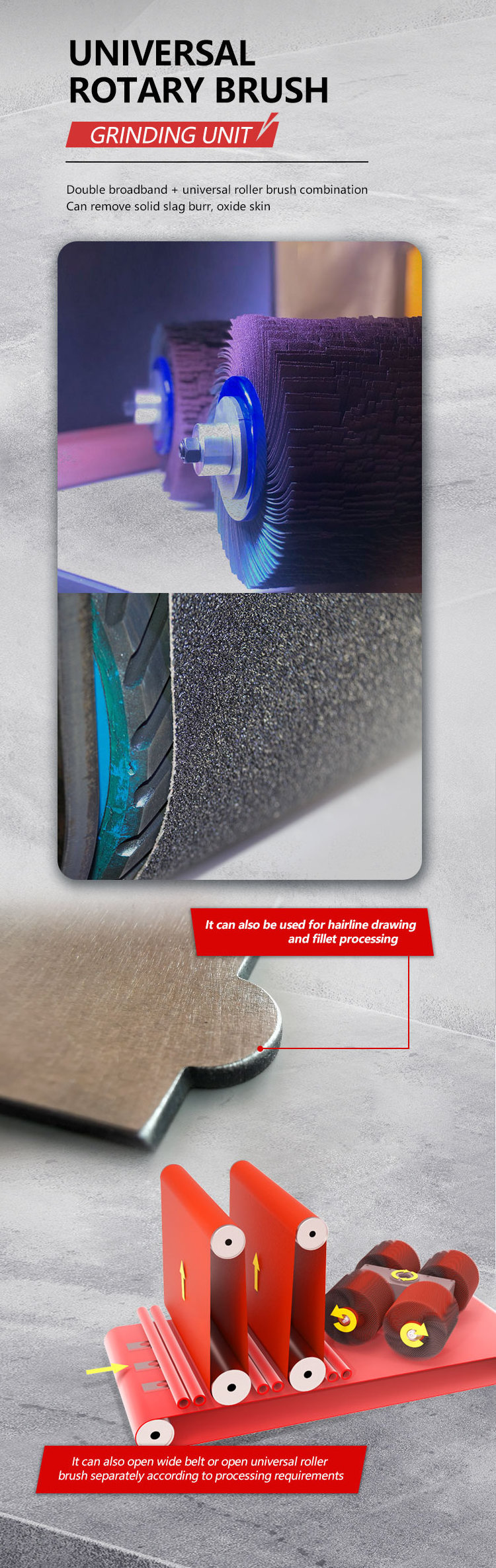

GRINDING UNIT

|

APPLICABLE MATERIAL

|

APPLICATION SCOPE

|

FUNCTION

|

|

QC916, QC930, QC1325

|

universal rollers

|

stainless steel, iron, copper, aluminum, alloy, coated sheet

|

1. Burr and sharp edge produced by stamping, cutting, etc.;

2.

Soft burr

of sheet metal produced by laser cutting

|

1. Remove lighter/softer burrs of parts' edge;

2. Chamfering for inner and outer edge

|

|

SS1000, R-R1000,

SM1000R-R

|

wide sand belt

|

stainless steel, carbon steel, iron, copper, aluminum, alloy sheet and wooden planks

|

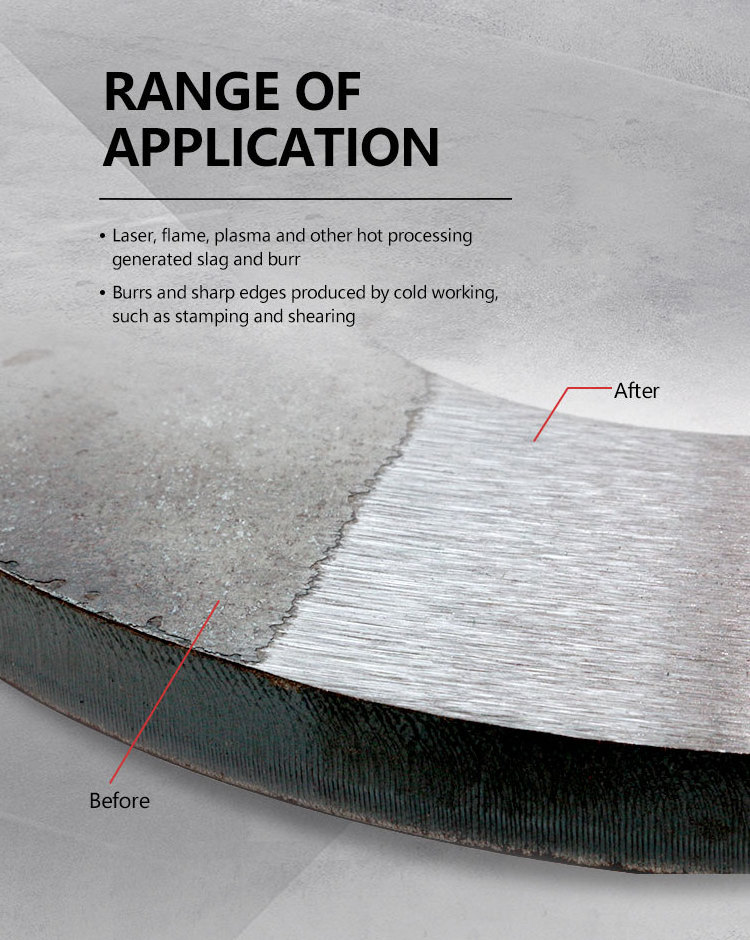

1.

Slag

and

burr

produced by laser, flame, plasma and other hot processing;

2. Burr and sharp edge produced by stamping, cutting, etc.

|

1. Remove solid slag and burrs from the surface of the workpiece;

2. Remove the surface rust and oxide layer of the workpiece;

3. Drawing of hair line on workpiece surface

|

|

SQ1000, SSQ1000,

SSQ1300

|

universal rollers + wide sand belt

|

stainless steel, carbon steel, iron, copper, aluminum, alloy sheet and coated sheet

|

|

1. Remove solid slag and burrs from the surface of the workpiece;

2. Remove the surface rust and oxide layer of the workpiece;

3. Chamfering for inner and outer edge;

4. Drawing of hair line and snow pattern on workpiece surface

|

Specification

|

item

|

value

|

|

Model

|

SSQ1000

|

|

Core Components

|

PLC, Grinding Unit

|

|

Key Selling Points

|

High Productivity

|

|

Applicable Industries

|

Construction works , Building Material Shops, Advertising Company, Machinery Repair Shops, Manufacturing Plant, wheel coating shops

|

|

Product name

|

sheet metal sanding deburring polishing machine

|

|

Function

|

Removal of burrs, edge chamfer

|

|

Application material

|

stainless steel, iron, copper, alloy, coated sheet

|

|

Max processing height

|

60mm

|

|

Fixed delivery mode

|

Magnetic adsorption + negative pressure adsorption

|

|

Voltage

|

AC 380V/50Hz

|

|

Max processing width

|

1000 mm

|

|

Sand belt width

|

1020 mm

|

|

Dimension

|

3020(L)*1960(W)*2100(H) mm

|

|

Weight

|

3200 kg

|

Hot Searches