- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V,380V

-

Dimension(L*W*H):

-

1300*1100*1200 mm

-

Weight:

-

700 kg

-

Product name:

-

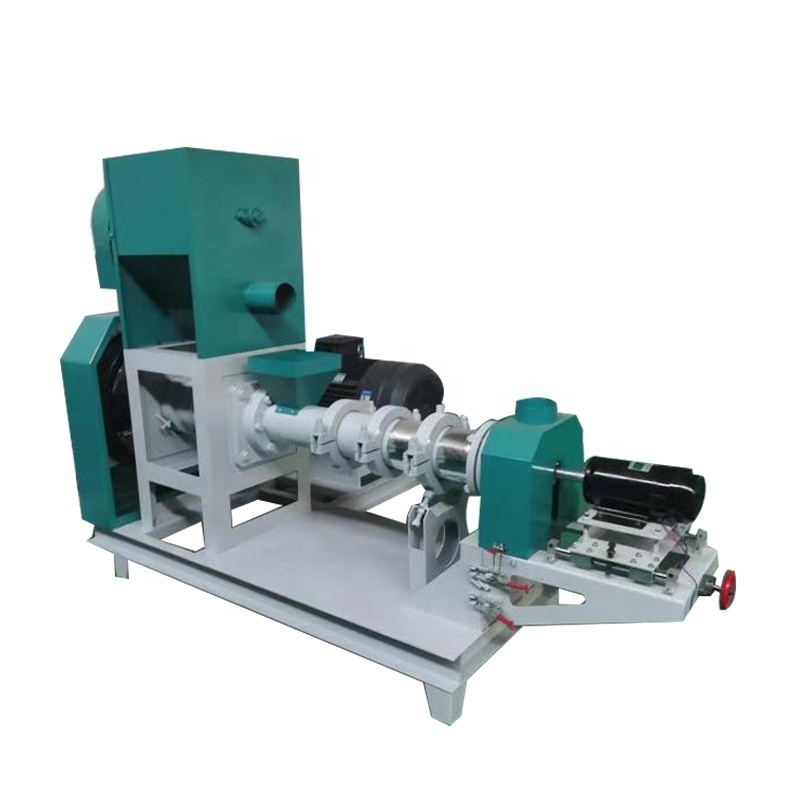

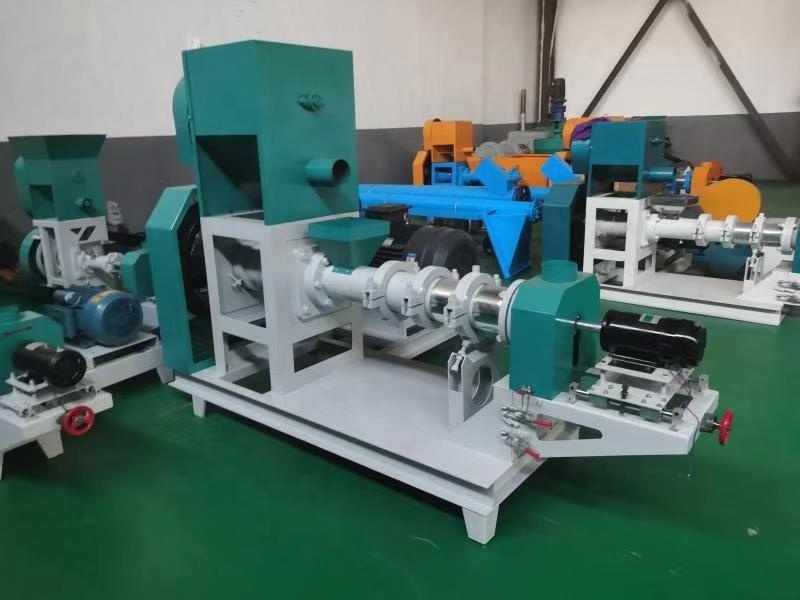

Animal Dog Cat Pellet Making Machine Floating Fish Feed Pellet Machine

-

Model:

-

HR80

-

Raw material:

-

Meat ,bones,chicken,cereal,etc

-

Color:

-

Clients' Requirement

-

Capacity:

-

200-300 kg/h

-

Power:

-

5.5kw

-

Driven Way:

-

Electricity Energy

-

Function:

-

Fish Feed Puffed Pellet Machine

-

Feature:

-

High Efficiency Low Cost

-

Advantage:

-

Easy Operation

Quick Details

-

Max. Capacity:

-

300kg/h

-

Place of Origin:

-

China

-

Brand Name:

-

HR

-

Voltage:

-

220V,380V

-

Dimension(L*W*H):

-

1300*1100*1200 mm

-

Weight:

-

700 kg

-

Product name:

-

Animal Dog Cat Pellet Making Machine Floating Fish Feed Pellet Machine

-

Model:

-

HR80

-

Raw material:

-

Meat ,bones,chicken,cereal,etc

-

Color:

-

Clients' Requirement

-

Capacity:

-

200-300 kg/h

-

Power:

-

5.5kw

-

Driven Way:

-

Electricity Energy

-

Function:

-

Fish Feed Puffed Pellet Machine

-

Feature:

-

High Efficiency Low Cost

-

Advantage:

-

Easy Operation

Factory Price Automatic Animal Dog Cat Pellet Making Machine Floating Fish Feed Pellet Making Machine

Fish feed making machine fish pellet making machine

The fish feed pellet making machine is widely used for process all kinds of grains into high-grade aquatic floating feed pellet for fish,catfish,shrimps,crab. It also can make pet feed for dog,cat etc with different shape and chicken feed.

Raw Material

The raw material is: Flour,corn meal ,soybean meal ,maize meal , meat meal,bone meal,fish meal etc.

Fitness: about 60-80mesh which were crushed and mixed.

Moisture content: about 20%-25%.

Features

1) . The fish feed pellets can float on water for over 20 hours.And sinking and floating aqua-feed pellets both can be made just by adjusting the feed formulation.

2) . Pellet diameter is 0.9mm-15mm by changing the mold.The cutter can cutting the pellets into different length.

3) The feeding speed,cutting speed,temperature all can be adjusted.

4) .The machine also can make feed for pet like dog,cat with different shapes and we can customized the sh a pe for you.

Working Principle of fish pellet feed machine :

This feed pellet extruder machine is suitable for making floating fish feed and other pet food with different shapes by changing different molds. The main material for making fish feed is maize powder and wheat flour. And we also can offer the whole line for making fish feed. It mainly consists the following parts:raw material-crusher-mixer-extruder-dryer or cooler(dryer has better effects, if you want to save cost, had better choose dryer)-flavoring parts(selectable)-packer.

Main performance characteristics of fish feed pellet machine:

1. Simple structure, wide adaptability, small floor space and low noise.

2.

powdered feed, grass powder can be granulated without adding a little

liquid, so the moisture content of the pellet feed is basically the

moisture content of the material before granulation, which is more

conducive to storage.

3. dry material processing, the production of feed pellets with high

hardness, smooth surface, internal ripening, can improve the digestion and

absorption of nutrients.

4. During the production process, under the pressure of the machine itself,

the starch in the feed can be matured to a certain extent, producing a

strong aroma, and the feed texture is hard, conforming to the

characteristics of the pig, cow and sheep, and improving the feed. The

palatability and easy to

eat.

5. The particle formation process can denature the pancreatic enzyme

resistance factor in grains and beans, reduce the adverse effects on

digestion, kill various parasite eggs and other pathogenic microorganisms,

and reduce various parasitic diseases and digestive tracts. Systemic

disease.

6. easy to feed, high utilization, easy to control the amount of feeding,

saving feed, clean and hygienic. Especially for fish farming, since the

pellet feed dissolves slowly in water, it is not drowned by sediment, which

reduces waste.

Packing

Shipping

The machine will be shipped with wooden case which has the plastic film inside, and will be delivered in 15 days after receives the payment.