- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

220V 50Hz, 220V 50hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIC

-

Dimension(L*W*H):

-

1950*750*1850mm

-

Weight:

-

750 KG

-

Keywords:

-

Aluminum tube filling sealing machine

-

Auto grade:

-

full auto

-

Filling speed:

-

40-60 tubes/min

-

Filling volume:

-

10-100ml

-

Machine material:

-

SUS304/316

-

Power:

-

2.5kw

-

Control:

-

Touch screen+button

-

Operator:

-

1 people

-

Main Function:

-

Filling sealing

Quick Details

-

Machinery Capacity:

-

30-60pieces/min

-

Packaging Material:

-

Wood

-

Filling Material:

-

paint ointment glue tube

-

Filling Accuracy:

-

99%

-

Voltage:

-

220V 50Hz, 220V 50hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MIC

-

Dimension(L*W*H):

-

1950*750*1850mm

-

Weight:

-

750 KG

-

Keywords:

-

Aluminum tube filling sealing machine

-

Auto grade:

-

full auto

-

Filling speed:

-

40-60 tubes/min

-

Filling volume:

-

10-100ml

-

Machine material:

-

SUS304/316

-

Power:

-

2.5kw

-

Control:

-

Touch screen+button

-

Operator:

-

1 people

-

Main Function:

-

Filling sealing

automatic shoe wax hair color tube filling and sealing machine is mainly used for aluminum and metal tube orienting, filling, sealing and printing. It has been widely used in the fields of cosmetic, food and chemical etc.

This automatic shoe wax hair color tube filling and sealing machine is pneumatic controlled, with 1 filling head and aluminum tube fold sealing stations. It has total 12 positions for filling and sealing. And materials such as paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, show wax, toothpaste etc., are all applicable.

|

Weight

|

800kg

|

|

Voltage

|

220V/50HZ

|

|

Filling Volume

|

5-75ml/30-150ml

|

|

Filling Accuracy

|

99%

|

|

Dimension

|

1950*800*1850mm

|

|

Power

|

2.2kw

|

|

Capacity

|

55-65 tubes/min

|

|

Air Pressure

|

0.6Mpa

|

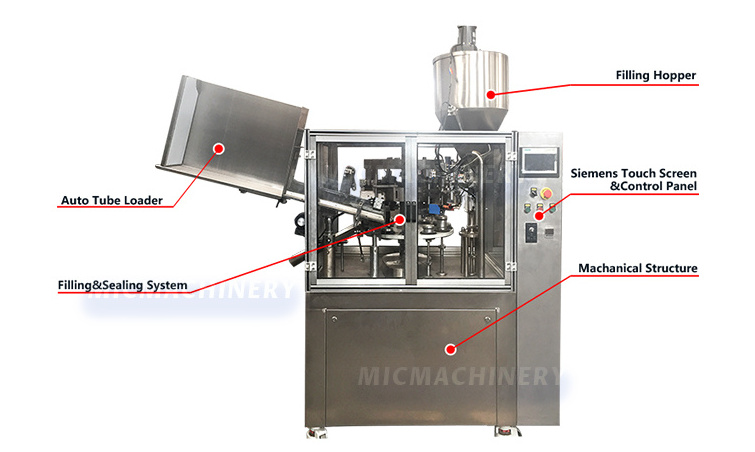

Machine whole look

This machine is used for aluminum and metal tube filling sealing

Automatic tube loader

A tube loader contains a loader and a tunnel. When tubes are put in the loader, they will be conveyed automatically to the working disk by the tunnel.

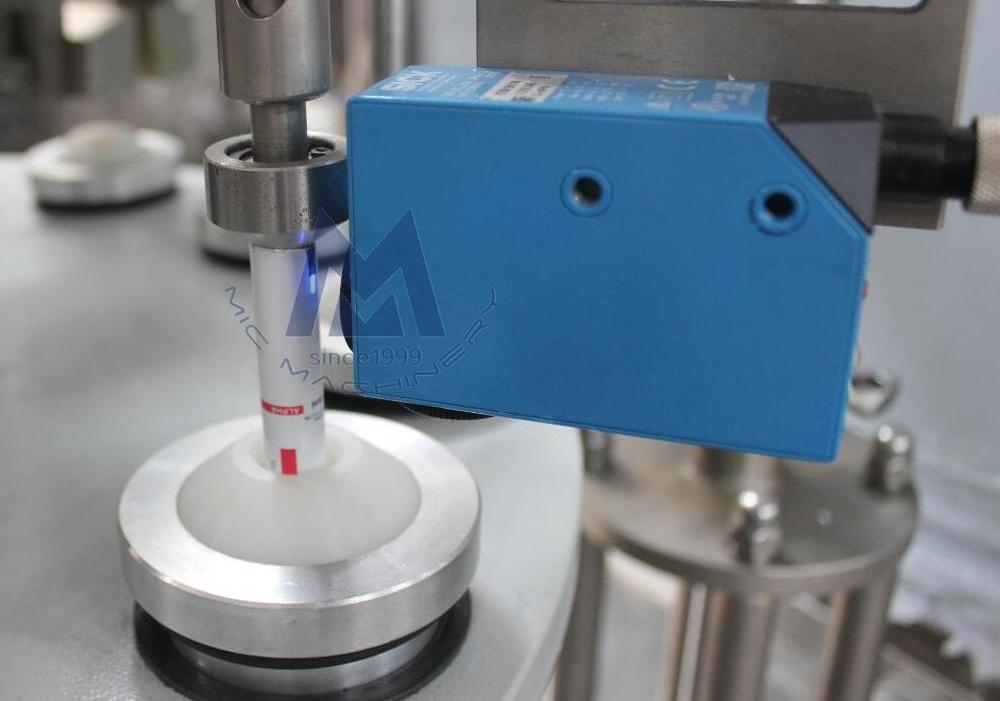

Mark senso

This sensor is for automatic orienting the tube according to the color mark on tube

Tail

Filling nozzle

This nozzle is special design for high viscosity material. And this filling nozzle need to be changed according to different tube diameter size

Aluminum tube tail folding stations

The stations are combined with Bend, Clamp and Fold Manipulator for sealing tube tail.

Hot Searches