- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

SHANDONG

-

Brand Name:

-

MONDE

-

Model Number:

-

MSB12

-

Weight:

-

1020

-

Max Jaw Opening:

-

cuostmized

-

Height:

-

cuostmized

-

Width:

-

cuostmized

-

Marketing Type:

-

Hot Product 2023

-

Application:

-

12-17 ton excavator

-

Name:

-

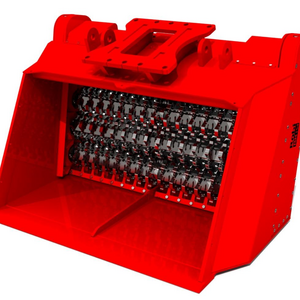

Rotary screening bucket

-

Color:

-

Cuostmized

-

Dimensions:

-

Cuostmized

-

Certification:

-

CE ISO

-

Overall weight:

-

1100kg

-

Material:

-

HARDOX 400

-

MOQ:

-

1 Set

Quick Details

-

Suitable Excavator(ton):

-

20ton, 1ton, 8ton

-

Bucket capacity:

-

cuostmized, Cuostmized

-

Bucket type:

-

Rotating screening bucket

-

Place of Origin:

-

SHANDONG

-

Brand Name:

-

MONDE

-

Model Number:

-

MSB12

-

Weight:

-

1020

-

Max Jaw Opening:

-

cuostmized

-

Height:

-

cuostmized

-

Width:

-

cuostmized

-

Marketing Type:

-

Hot Product 2023

-

Application:

-

12-17 ton excavator

-

Name:

-

Rotary screening bucket

-

Color:

-

Cuostmized

-

Dimensions:

-

Cuostmized

-

Certification:

-

CE ISO

-

Overall weight:

-

1100kg

-

Material:

-

HARDOX 400

-

MOQ:

-

1 Set

MONDE Factory Supplying mini rotary bucket for sifting sand screening bucket for Caterpillar

Product Description

MONDE rotary screening bucket comes equipped with an interchangeable mesh system around the drum inner circumference and replaceable sections in the conical rear area of the drum. Five models are offered to fit mini diggers from 2 tonne to 36 tonne excavators.

Suitable for top-soil, quarried stone, remediation of contaminated soils beaches, demolition waste and green recycling duties.

MONDE rotary screening bucket is just at home clearing on a demolition site or in the quarry cleaning and sizing stone.

|

Model

|

MSB02

|

MSB08

|

MSB12

|

MSB16

|

MSB18

|

|

Machine Class(t)

|

2-4

|

6-10

|

12-17

|

18-23

|

25-36

|

|

Rotary Screen Diameter(mm)

|

610

|

810

|

1000

|

1350

|

1500

|

|

Rotating Speed(r/min)

|

60

|

65

|

65

|

65

|

65

|

|

Working Pressure(bar)

|

150

|

220

|

230

|

250

|

250

|

|

Oil Flow(L/min)

|

30

|

60

|

80

|

110

|

110

|

|

Weight(kg)

|

175

|

630

|

1020

|

1920

|

2430

|

Product Display

MONDE rotary screening bucket is discharged through the discharge opening at the end of the drum. Due to the turning and rolling of the material in the drum, the material stuck in the screen hole can be ejected to prevent the screen hole from being clogged.MONDE rotary screening bucket is more flexible to install on the excavator and more convenient to move, which provides better support for the project.

Product Details

The mesh hole is not easy to block.

The screening cylinder can be rotated forward and backward for easy screening.

Simple structure and convenient maintenance.

Certificate

Advantages

Designed by professional manufacturers, the output and reliability of the screening system are improved, the operation is simple and the quality is reliable, and there is a perfect after-sales system.

There are three types of screening bucket type and blade angle.

A and B are versatile and are suitable for the screening of ordinary dry silt materials.

The C special type is especially suitable for screening materials with high viscosity sludge.

1.Suitable for excavators of different brands and tons.

2.The screening mesh can be made to order from 1mm to 120mm, according to your requirement.

3.Customize product color according to your need.

Applications

Packaging & Shipping

1.Rotary screening bucket is packed in wooden box and Tito, also can be packed according to your needs.

2.Fast delivery time:5-7 days for small quantity,and 20-30 days for container quantity

3.We have a team specialized in packing and loading container, they have rich experience and can load the max quantity products,which can help customer save the ocean freight.

About Us

Shandong Mingde Machinery is a well-known global enterprise in the R&D,manufacturing,sales and service of multifunctional attachments.Mingde always adheres to the human resources management idea"scientific and technological innovation,talents base".During committing to the safe production and standard operation, the company organizes staff to carry out a series of comprehensive training and cultural

activities,striving to build a solid,united and diliaent excellent team.Mingde has established strateaic partnership with SSAB Company in Sweden and a member of HARDOX IN MY BODY global club and HARDOX WEARPARTS global processing center. In technology research and development, mass production and marketing sales, Mingde has opened deep cooperation with Ueda Company in Japan,which greatly improved the company's core competitiveness and made the company get more than 30 patents of utility model. Mingde has passed the ISO9001 intemational quality system certification,SGS testing certification,CE European safety certification and ISO14001 environmental manacement system certification...

Hot Searches