- Product Details

- {{item.text}}

Quick Details

-

Printing Type:

-

Offset Printing Machine

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MATURA

-

Application:

-

Any flexo printing machie

-

LPI:

-

can be 80-2000

-

Material:

-

45#steel

-

Usage:

-

Flexo machine

-

Diameter range:

-

40-600mm

-

Maximum width:

-

5000mm

-

Screen angle:

-

1-89 degree

-

Payment:

-

VISA,T/T,Weston Union and etc.

-

Shipping Method:

-

By Sea,DHL,Fedex,TNT and etc.

Quick Details

-

Condition:

-

New

-

Type:

-

Roller

-

Use:

-

For Heidelberg Printer

-

Printing Type:

-

Offset Printing Machine

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

MATURA

-

Application:

-

Any flexo printing machie

-

LPI:

-

can be 80-2000

-

Material:

-

45#steel

-

Usage:

-

Flexo machine

-

Diameter range:

-

40-600mm

-

Maximum width:

-

5000mm

-

Screen angle:

-

1-89 degree

-

Payment:

-

VISA,T/T,Weston Union and etc.

-

Shipping Method:

-

By Sea,DHL,Fedex,TNT and etc.

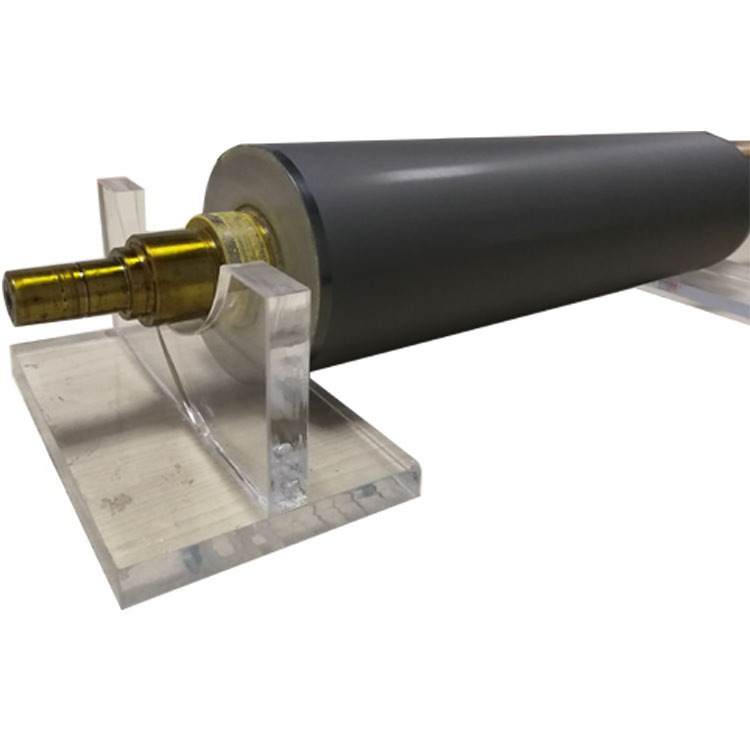

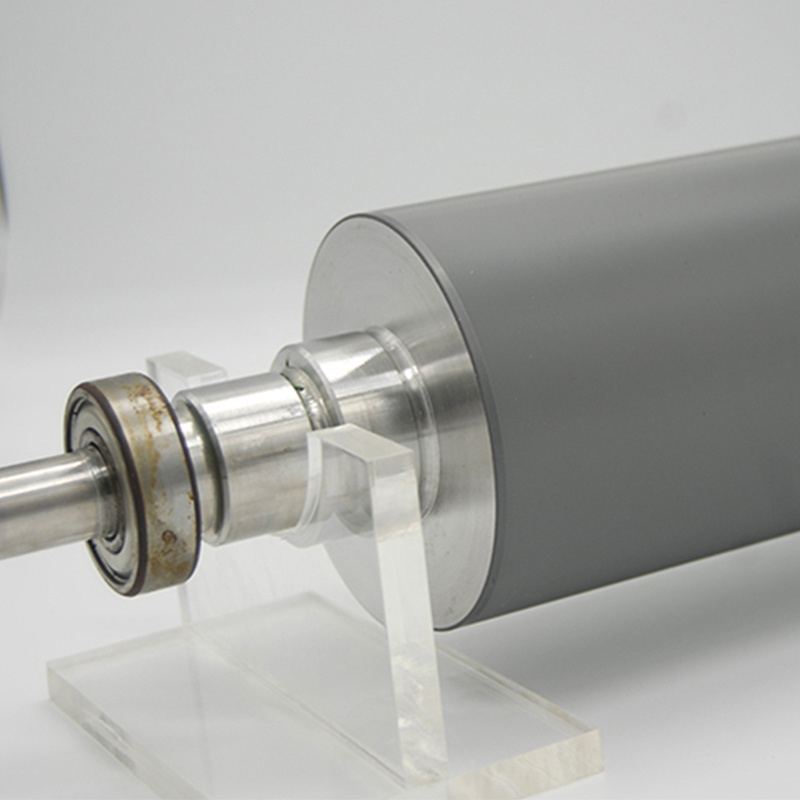

Flexo Printing Ceramic Anilox Rollers Manufacturer

Main Features Of The Anilox Roller Ceramic:

1.Anti-fraying, Anti-corrosive, Thermo stability, Long-life service and cost-sacking.

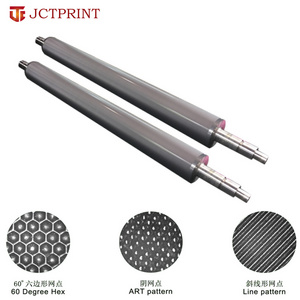

2. The cell engraved by ALE fiber laser engraving machine, has a large quantity of ink-containing.And the cell has a regular shape and a smooth cell-wall and cell-bottom. Thus , not only can the ink in the cell release quickly , but also it can easily to clean

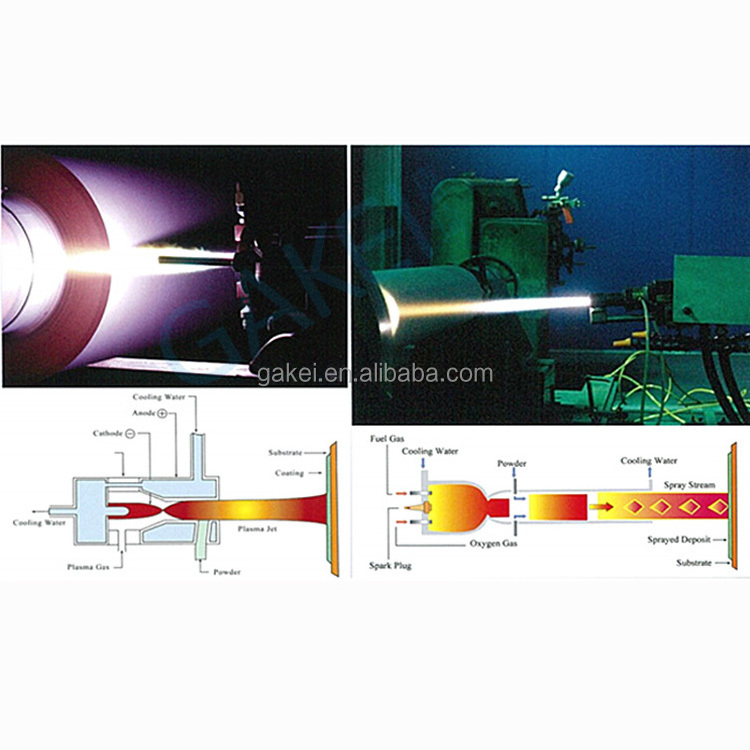

3. Taking strict process of plasma-sprayed ceramic layer, guarantees the porosity , the thickness and the uniformity of the layer

4. Combined with the super-alloy stainless steel layer to ensure the solid combination of the ceramic layer and the roller base. So , it can present the corrosive substance of the printing ink to plug into the roller base effectively

5. Providing all the products the cell-volume detecting report to ensure the accuracy of the cell’s ink-containing.

Our Advantage

1.Base roller

material:

45# steel tube or No5 series aluminum

General performance requiremen:

45# steel tube

thickness:

We can also make the special thickness according to customers requirement.

strict inspection procedure of base roller:

Incoming inspection including surface roughness,straightness, dynamic balance,cylindricity and so on.

2.Chrome oxide ceramic layer

Using the famous plasma spraying machine from Switzerland supplier.

The evenness of 80% ceramic powder can be controlled between 15u-35u

The hardness of chrome oxide ceramics can reach 1200HV.

3.Antiseptic treatment

we use the nanoscopic sealant to coat on the surface of the ceramic which can reach the tiny cell to protect the base roller from solvent corrosion.

4.Precise delivery on the inks

We make trial engraving before the real engraving.

We use the scanner to scan each layer to test the volume of the cell

According to the realationship between the LPI and BCM , we can make sure whether the LPI is ok.

5.Quality Control

We have the quality control system during the whole production from the very beginning to the end and our principle is to make sure each roller is qualified.

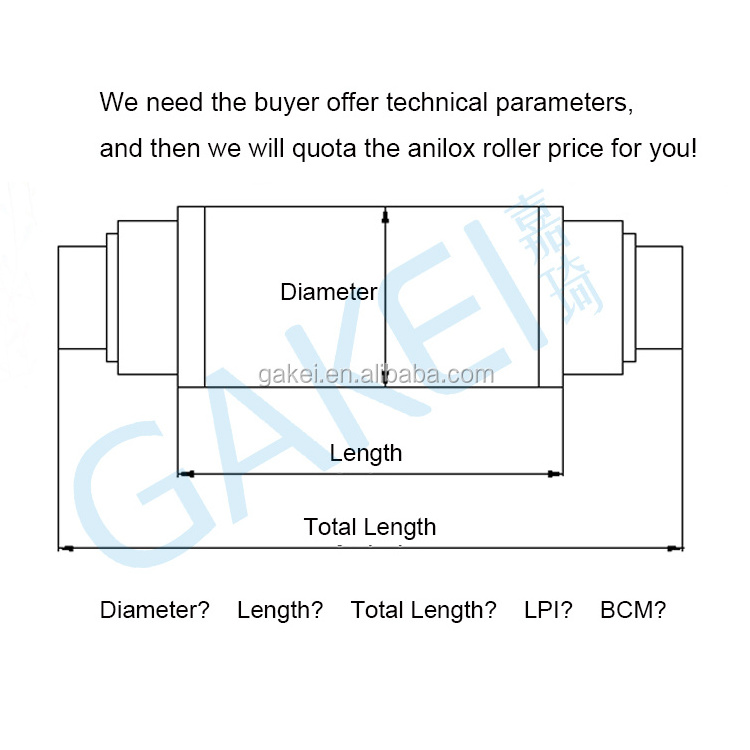

Custom instructions:

Please provide customized roller size (diameter, length) and other special requirements,

and fax the design drawings to our company.If you do not have the design drawings, please

contact our company, the engineer will provide you with professional solutions.

Maintenance of anilox roller

The anilox roller is a precision component that needs to be cleaned regularly to

prevent ink from solidifying and blocking the anilox holes.Usually divided into two types

of cleaning:

1. Steel brush with special cleaning agent.

2. Use ultrasonic cleaning machine for cleaning.

Specification:

| Item Type | Flexo Printing Ceramic Anilox Rollers Manufacturer |

| Usage | Flexo machine |

| Screen count range | 30-2000 LPI |

| Maximum width | 5500mm ( with axis) |

| Diameter range | 25-600 mm |

| Screen angle | 1-89 degree |

| Cell shape | Hexagon,Diamond,Tri-heliCal and other special shapes. |

| MOQ | 1PC |

| Cell Angle | 60°,45°,30°and other special requirements |

| Delivery | About 25 working days after payment received |

| Payment | VISA,T/T,Weston Union and etc. |

| Shipping Method | By Sea,DHL,Fedex,TNT and etc. |

Delivery:

Delivery in 20 days after payment received

Packaging:

Standard export wooden carton, also can be packaged as customer's requirement.

Detail:according to customer’s requirement.