- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Staircase

-

Design Style:

-

Modern

-

Place of Origin:

-

Guangdong, China

-

Material:

-

stainless steel 304 or 316

-

Surface Finish:

-

mirror or satin

-

Pillar Height:

-

1050mm,930mm,850mm

-

Glass Height:

-

1150/1050/95mm/Customized

-

Base Holes:

-

3nos per meter

-

Glass Thickness:

-

10/12mm

-

Top Handrail:

-

Slot Pipe- Round or Square

-

Side Cover:

-

Non / Stainless Steel

-

Anchor Bolt:

-

Included

-

Rubber:

-

Included

Quick Details

-

Warranty:

-

5 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

graphic design

-

Application:

-

Staircase

-

Design Style:

-

Modern

-

Place of Origin:

-

Guangdong, China

-

Material:

-

stainless steel 304 or 316

-

Surface Finish:

-

mirror or satin

-

Pillar Height:

-

1050mm,930mm,850mm

-

Glass Height:

-

1150/1050/95mm/Customized

-

Base Holes:

-

3nos per meter

-

Glass Thickness:

-

10/12mm

-

Top Handrail:

-

Slot Pipe- Round or Square

-

Side Cover:

-

Non / Stainless Steel

-

Anchor Bolt:

-

Included

-

Rubber:

-

Included

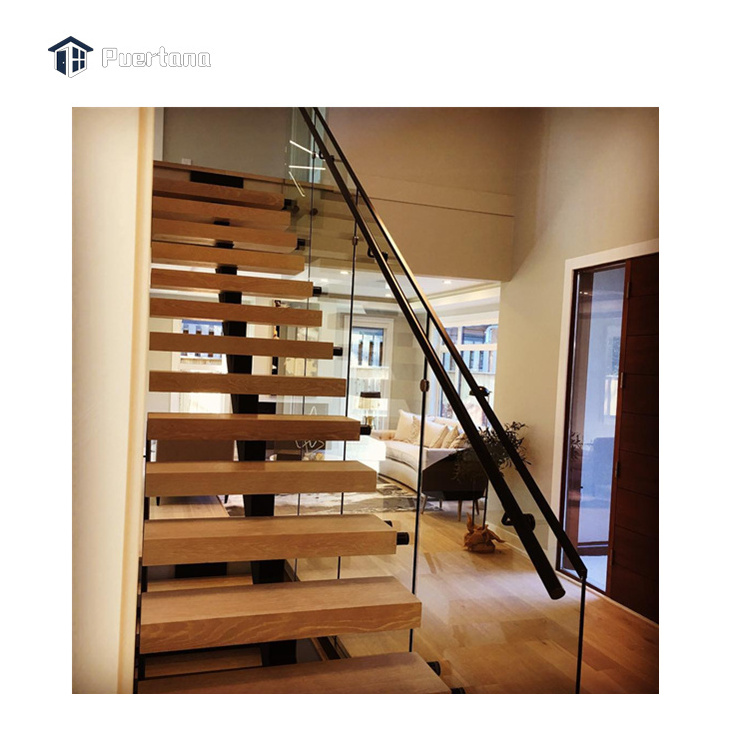

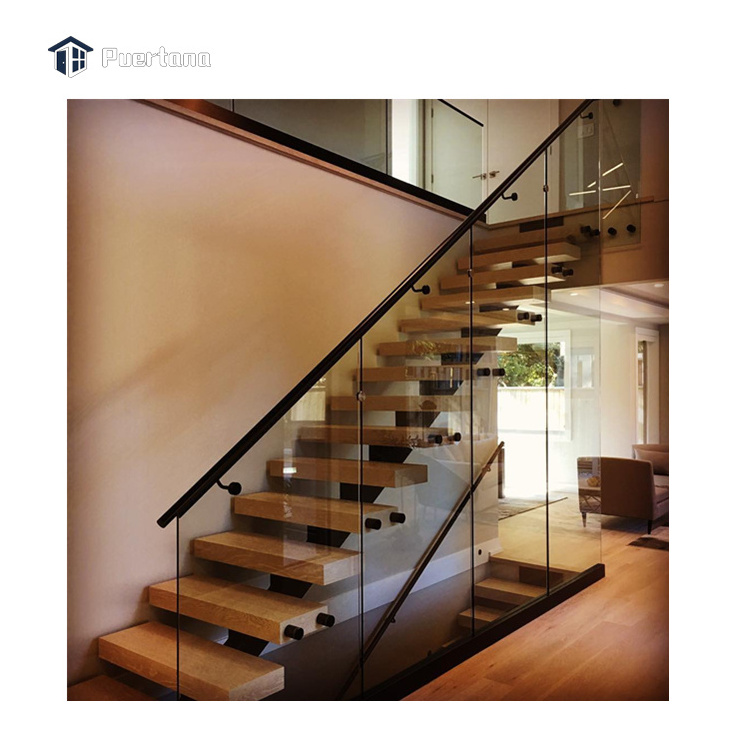

How To Design a Cantilevered Staircase

Staircases are a lot of fun. That is, even though the design process is strictly regulated by the building code, it can be the perfect opportunity to flex your creative muscles. But how exactly do you design a cantilevered staircase? How do the stairs stay in place? And what do you need to take into consideration during the design phase?

Product Description

|

Size

|

Floor height

|

Customized as your job site

|

|

|

|

Width

|

700 - 1500mm

|

|

|

Material

|

Tread

|

Laminated glass /Tempered glass /Solid wood /Marble /Stainless steel /Wrought iron

|

|

|

|

Railing

|

Glass Railing/Stainless steel cable railing/Stainless steel rod railing/wrought iron railing

|

|

|

Component & Size

|

Tread thickness

|

30 to 100mm solid wood tread

|

|

|

|

|

10+1.52+10+1.52+10mm or 12+1.52+12mm tempered laminated glass tread

|

|

|

|

Handrail

|

dia=50.8mm or square=50*50mm

|

|

|

|

Baluster

|

dia=50.8mm or 42.4mm

|

|

|

|

Glass

|

12mm thick

|

|

|

Finish

|

Stainless steel

|

Mirror / satin

|

|

|

|

Carbon steel

|

Hot dip galvanizing / powder coating / painting

|

|

|

|

Aluminum

|

Powder coating / galvanized / oxidize

|

|

|

|

Solid wood

|

Painting

|

|

|

|

Glass

|

Clear / frosted/ tinted

|

|

|

MOQ

|

1 Set

|

|

|

|

Delivery Time

|

About 30 days

|

|

|

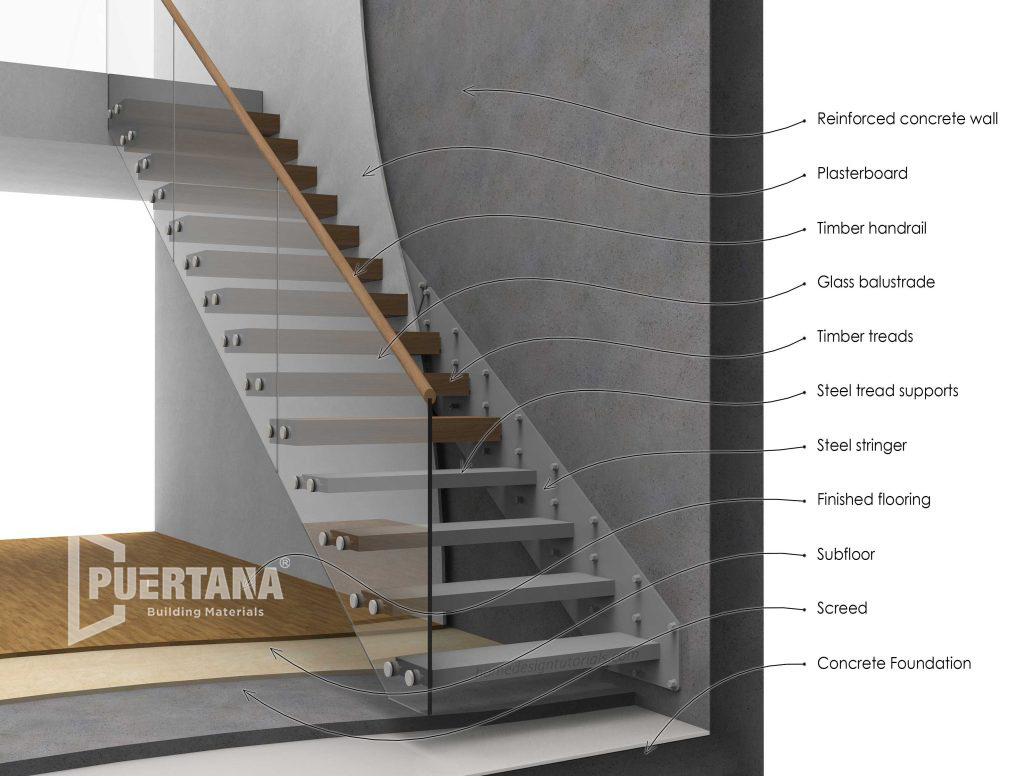

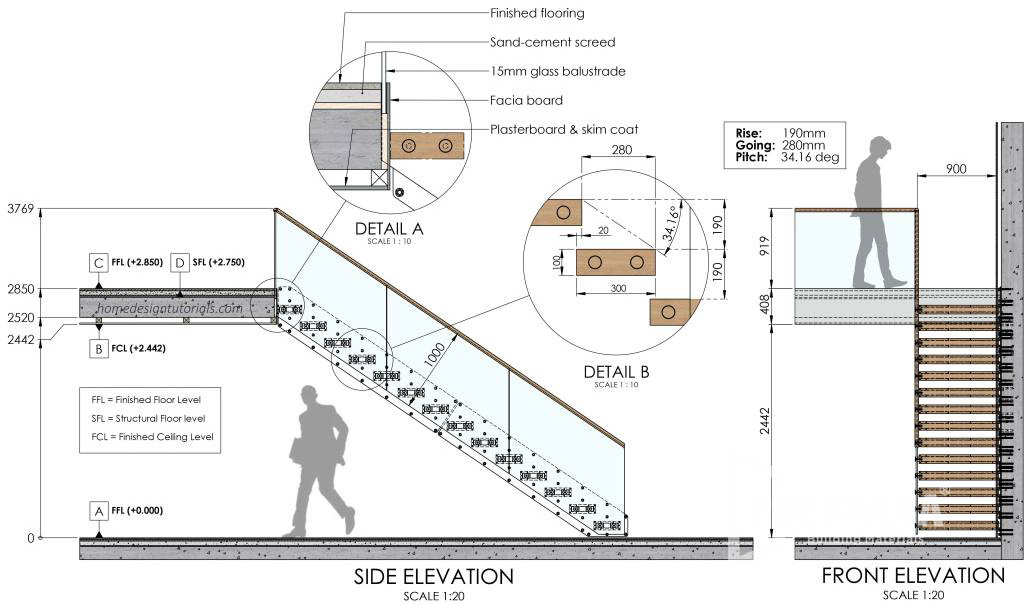

FIGURE 1 – Cantilevered Staircase Details

We’ll tackle these questions by first having a look at the relevant building regulations, and then moving onto understanding the basic physics behind designing and building a cantilevered staircase. This is where it gets a bit more technical – but don’t worry– we won’t get carried away with complex equations. We’ll mainly focus on finding out maximum displacement and the basic stresses under expected loading conditions, i.e. under every day use.

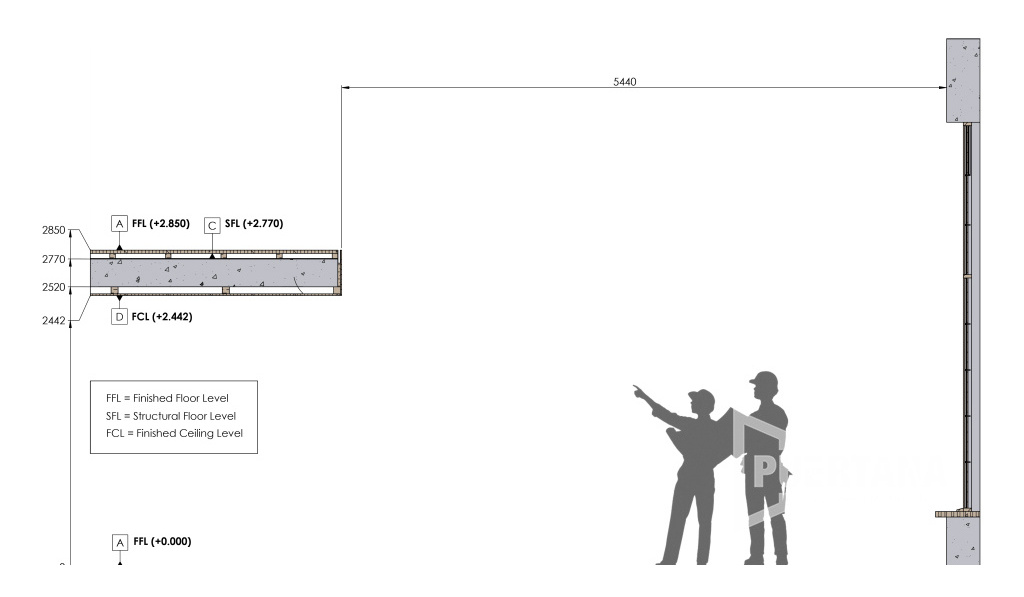

FIGURE 2 – Measuring Floor-to-Floor Dimension

To work out the number of risers, we need to pick a number that falls within the specified range (150 – 220mm) and divide the floor-to-floor dimension with that number. Remember that we need a whole number here, so we’ll round it up to the nearest number if we end up with decimals.

We can’t have half risers on our staircase, right? So, in this case, we’ll divide 2850mm by 190mm, resulting in 15. This means that our staircase will have 15 steps, each with a rise of 190mm.

We can’t have half risers on our staircase, right? So, in this case, we’ll divide 2850mm by 190mm, resulting in 15. This means that our staircase will have 15 steps, each with a rise of 190mm.

FIGURE 3 – Measuring Floor-to-Floor Dimension

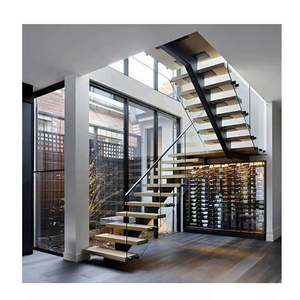

Now that we have the main dimensions worked out, we can start designing our staircase. In Fig. 4 below we can see the full staircase is made up of two sections – top and bottom flight assembly. So although at a first glance the staircase looks like it’s made from solid timber treads, there’s actually a steel structure underneath it all.

STRINGER

The stringer is the backbone of the steel structure as it supports the cantilevered treads and acts as a fixing plate for the whole staircase. Therefore it needs to be strong enough to withstand the stresses and rotational forces that are introduced while the stairs are being used.

This is why there are four fixing points at the centreline of each tread. By using multiple fixings per tread, the forces are shared evenly which keeps the stringer nice and rigid.

This is why there are four fixing points at the centreline of each tread. By using multiple fixings per tread, the forces are shared evenly which keeps the stringer nice and rigid.

FIGURE 5 – Cantilevered Staircase Fixing Detail

The fixing detail in Fig.5 above shows us how the end of the staircase is fixed to the wall. This is what the word cantilever means – fixed at one end only. You may have heard the term floating stairs thrown around, which is another term to describe cantilevered stairs.

This ‘floating’ effect is achieved by hiding the fixings and support structure from sight, making it appear as if the stairs are floating. Here the stringer and fixings are hidden behind a plasterboard finish which is offset from the concrete wall.There are four lengths of M16 studding resin anchored at the centreline of each tread. We’ll see why we need this many fixings in the structural analysis a bit later, but first let’s familiarise ourselves on how resin anchoring actually works.

This ‘floating’ effect is achieved by hiding the fixings and support structure from sight, making it appear as if the stairs are floating. Here the stringer and fixings are hidden behind a plasterboard finish which is offset from the concrete wall.There are four lengths of M16 studding resin anchored at the centreline of each tread. We’ll see why we need this many fixings in the structural analysis a bit later, but first let’s familiarise ourselves on how resin anchoring actually works.

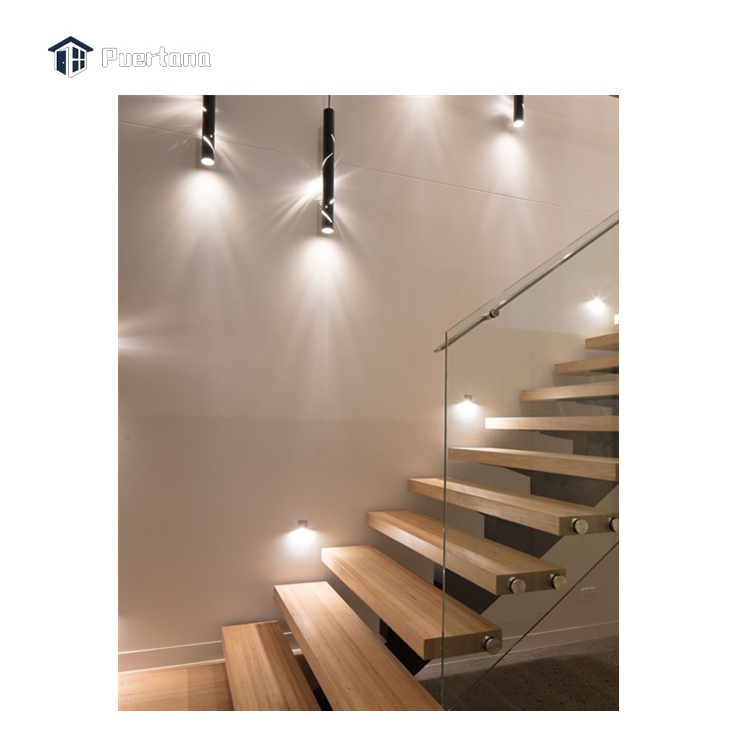

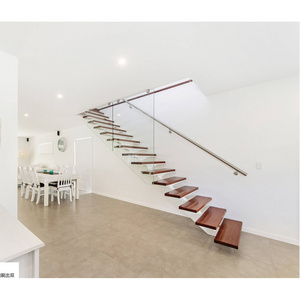

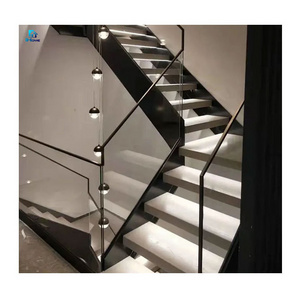

STRAIGHT STAIRCASE

Modular open staircases custom designed and built with stainless or powder-coated stainless steel, wood, and glass.

Hot Searches