- Product Details

- {{item.text}}

Quick Details

-

Range of Spindle Speed(r.p.m):

-

10 - 12000

-

Repeatability (X/Y/Z) (mm):

-

0.003

-

Place of Origin:

-

guangdong

-

Brand Name:

-

LC-V1160

-

Model Number:

-

1160

-

Table Travel (mm):

-

550*1200

-

Year:

-

NEW

-

Voltage:

-

380V;50/60HZ

-

Dimension(L*W*H):

-

2800*2400*2950

-

Weight (KG):

-

5800

-

Spindle Motor Power(kW):

-

11

-

Max. Table Load(kg):

-

800 kg

Quick Details

-

Table Travel (X) (mm):

-

1100

-

Table Travel (Y) (mm):

-

600

-

Table Travel (Z) (mm):

-

600

-

Range of Spindle Speed(r.p.m):

-

10 - 12000

-

Repeatability (X/Y/Z) (mm):

-

0.003

-

Place of Origin:

-

guangdong

-

Brand Name:

-

LC-V1160

-

Model Number:

-

1160

-

Table Travel (mm):

-

550*1200

-

Year:

-

NEW

-

Voltage:

-

380V;50/60HZ

-

Dimension(L*W*H):

-

2800*2400*2950

-

Weight (KG):

-

5800

-

Spindle Motor Power(kW):

-

11

-

Max. Table Load(kg):

-

800 kg

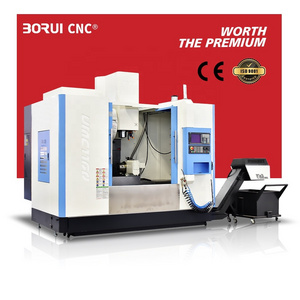

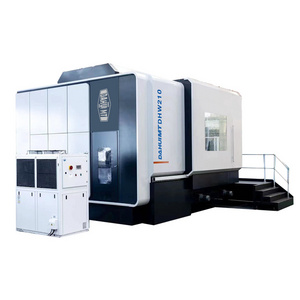

Product Description

Technical characteristics, parameters and configuration

1.1 Technical characteristics

The V1160 vertical machining center adopts the Japanese imported control system (Mitsubishi) and its supporting servo driver and motor to realize three-axis linkage. It is suitable for suitable batches of parts that are complex, have many processes, require high accuracy, need to use a variety of ordinary machine tools and a variety of tools and toolings, and can only be completed after many clamping and adjustments. It mainly processes box types, complex curved surfaces, special-shaped parts, plates, sleeves and plate parts. It is widely used in electronics, machinery, automobiles, aircraft, aerospace, ships, national defense and other products.

Whole machine structure: The main components of the fuselage are cast with high-quality HT300 marked cast iron, and the internal muscles and bones are strengthened. All of them have been tempered, and finite element analysis has the characteristics of high strength, good stability and not easy to deform, which ensures the rigidity of the whole machine and the accuracy and stability of long-term use.

Spindle: Box spindle head structure, internal muscle and bone reinforcement, P4-level ultra-precision bevel ball bearing and long-span support design, so that the spindle can withstand strong radial and axial thrust and eliminate vibration caused by heavy-load cutting.

Equipped with the spindle of Taiwan's famous brand. The nose design of the spindle is combined with the dustproof of the spindle air curtain, which can prevent debris from entering and ensure the accuracy and life of the spindle.

Imported oil coolers cool the spindle, improve the service life of the bearing, and reduce the thermal deformation of the spindle on the machining accuracy.

Transmission parts: imported precision bearings and Taiwan high-quality precision ball screws. The installation of the ball screw adopts a pre-stretching process. While improving the rigidity of the transmission part, it eliminates the elongation of the ball screw caused by the thermal stress effe

Specification

|

Fuselage

|

Jianchi Custom HT300

|

|

Control system

|

Japan Mitsubishi M80B

|

|

Spindle motor

|

Mitsubishi Japan

|

|

X/Y/Z axis motor

|

Mitsubishi Japan

|

|

Main axis

|

Taiwan Weller Ruien

|

|

Ball screw.

|

Taiwan Shangyin/Yintai C3

|

|

Line track

|

Taiwan/Germany

|

|

Bearing

|

Shangyin/Yintai/Rexroth

|

|

Precision locking nut

|

X45-3/Y45-2/Z45-3

|

|

Coupling

|

Japan

|

|

Cooling system

|

KOYO/NACHI

|

|

Lubrication system

|

Taiwan Yingxi

|

|

Knife warehouse

|

Shanggong

|

|

Main pneumatic components

|

JOY

|

|

Transformer

|

Baoteng/Deyang

|

|

Hand wheel

|

Taiwan joint venture Gutian

|

|

Main electrical components

|

Taiwan SHAKO

|

|

DC stabilized power supply

|

Dongling

|

|

Spindle oil cooler

|

Binjie

|

|

Electric box heat exchange

|

Binjie Schneider.

|

|

Workbench travel (X-axis)

|

1100mm

|

|

Saddle stroke (Y-axis) |

600mm

|

|

Spindle box travel (Z-axis)

|

600mm

|

|

Distance from spindle end to work surface

|

100-700mm

|

|

Workbench size

|

550*1200mm

|

|

Workbench load bearing

|

800KG

|

|

T-shaped slot size |

5MM-18Self

|

|

Specification of knife handle

|

BT40

|

|

Installation diameter

|

Φ150MM

|

|

Specifications for pulling nails

|

BT40 45°

|

|

Rotational speed range

|

12000/10000 r/min

|

|

Maximum output torque

|

|

|

Spindle motor power

|

Leather belt D11.Direct connection DG11 KW

|

|

Maximum output torque

|

|

|

Three-axis motor power

|

3-3-3 KW

|

|

X, Y, Z-axis fast-shift speed

|

36 m/min

|

|

Tool capacity of disk knife library

|

24 Hold

|

|

Maximum diameter/length/weight of disk tool library

|

80MM/200MM/8KG

|

|

Maximum diameter of the tool in the disk tool library (adjacent without tool)

|

150mm

|

|

Disc knife library knife selection method

|

Pick freely |

|

Disc tool library tool exchange time (knife-knife)

|

3.5s

|

|

Positioning accuracy (X/Y/Z)

|

0.003/0.003/0.003 mm

|

|

Repeat positioning accuracy (X/Y/Z)

|

0.003/0.003/0.003 mm

|

|

External dimensions of machine tools

|

2800*2400*2950 mm

|

|

Total electrical capacity of machine tools

|

20KVA

|

|

Mainframe weight

|

5800Kg

|

Production Process

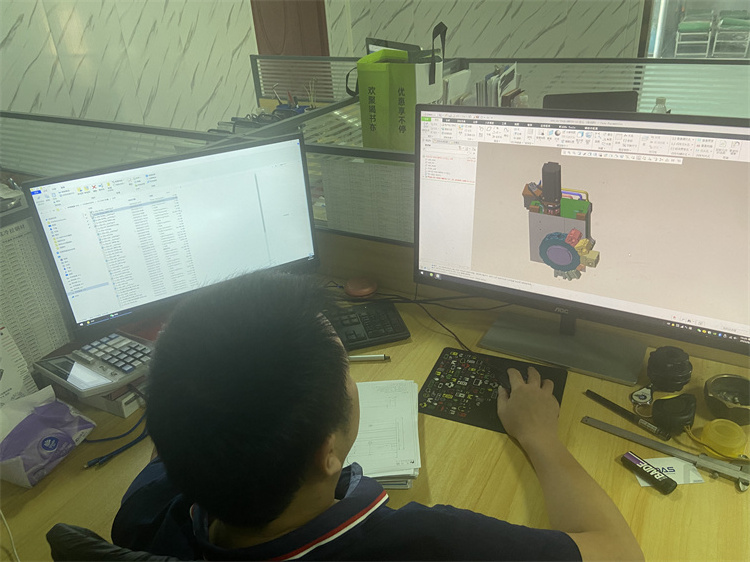

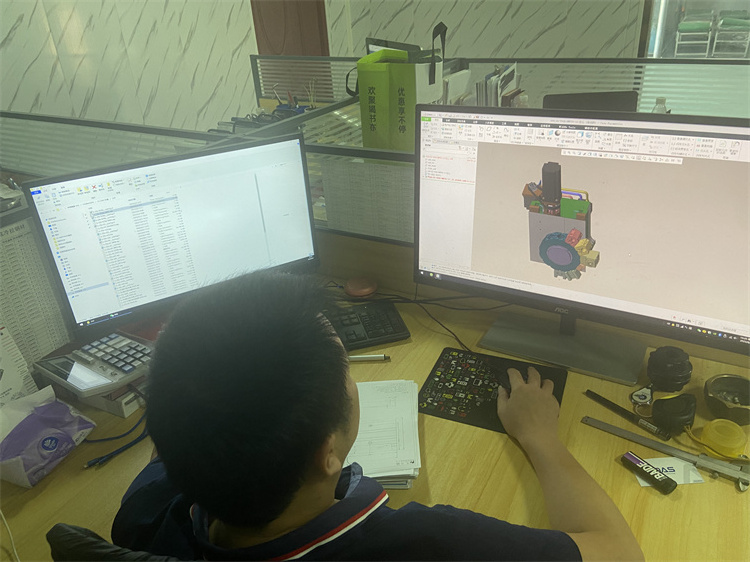

R & D design

Parts warehouse

Hardware installation

Installation of the whole machine

Debugging

Finished goods warehouse

Hot Searches