|

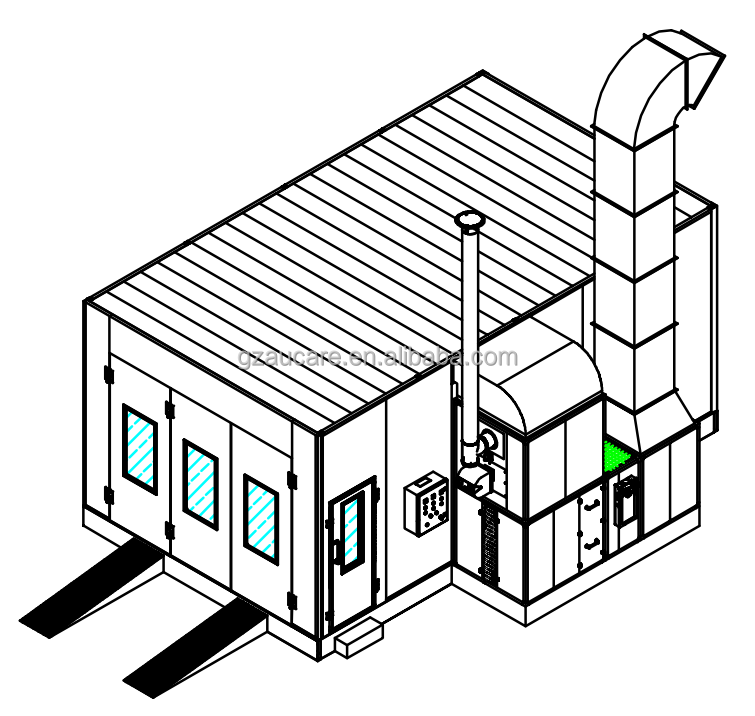

BOOTH DIMENSIONS

|

|

|

Internal dimensions

|

6900×4000×2650 mm (L*W*H)

|

|

External dimensions

|

7010×5410×3410 mm (L*W*H)

|

|

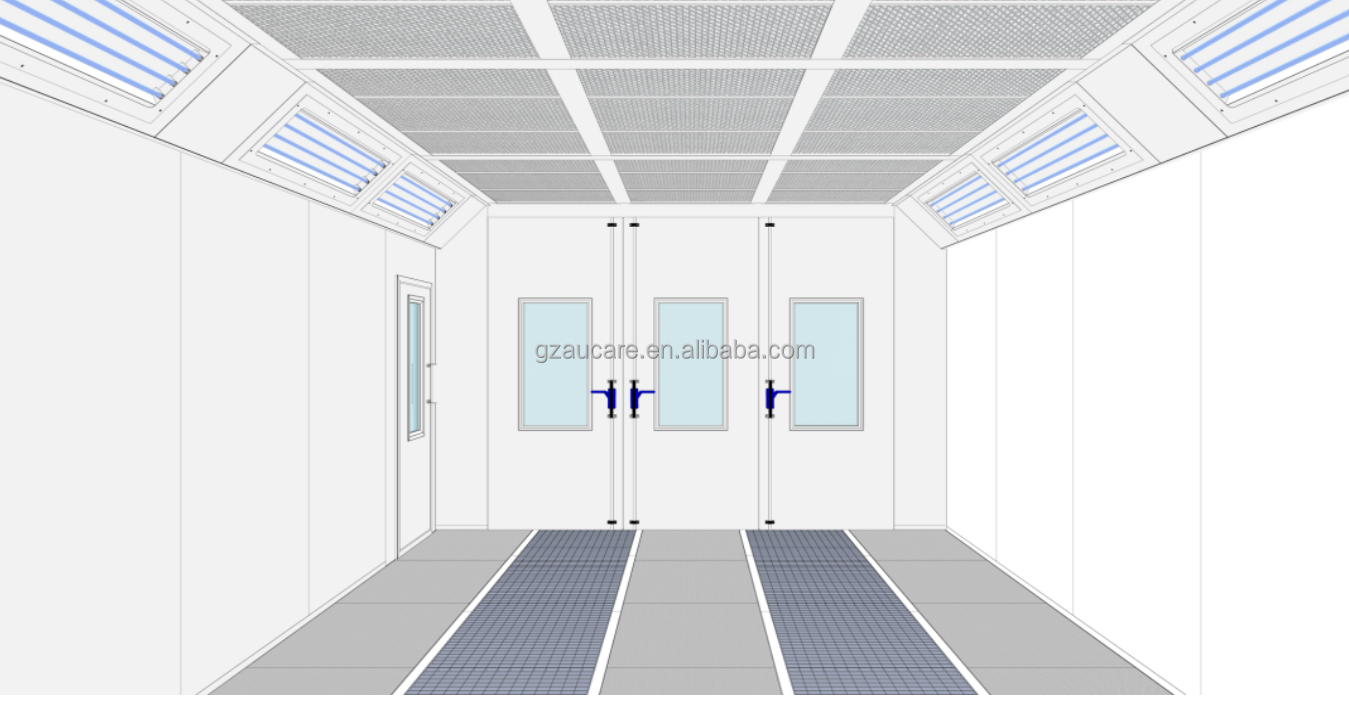

BASEMENT

|

|

|

Base design

|

Made of galvanized steel sheet

2 rows of grids and 3 rows of diamond plates

Basement(H): 300mm

|

|

Carrying capacity of the grids

|

650kg/wheel

|

|

Filter area

|

10m2

|

|

Drive-in-ramps

|

2 pcs, 2000X625X280 mm/pc (L*W*H), diamond plates

|

|

Grid description

|

Grids:30x4 mm steel grates with twisted bars, spacing of twisted steel is 100mm.

|

|

CABIN

|

|

|

Cabin structure

|

Vertical wall panel

|

|

Plenum height

|

400mm

|

|

Ceiling filter design

|

Made of galvanized steel sheet, C sharp groove structure

|

|

WALL PANEL

|

|

|

Wall panel

|

50mm dual-skin insulated panels filled with heat resistant rock wool substrate thickness: 0.426mm

|

|

Top panel

|

Single-layer galvanized steel plate bending forming

|

|

Profile material

|

1.0mm color steel plate bending forming

|

|

ENTRANCE DOOR

|

|

|

Form

|

Manual door, 3-wing entry door (“2 + 1” structure)

|

|

Size

|

3200×2550 mm (W*H)

|

|

Quantity and arrangement

|

Entry door, 1 set

|

|

Door description

|

Containing frame, with safety glass observation window

|

|

PERSONNEL DOOR

|

|

|

Form

|

Frame structure

|

|

Size

|

800×2000 mm (W×H)

|

|

Quantity

|

1 set

|

|

Door description

|

With safety glass observation window

|

|

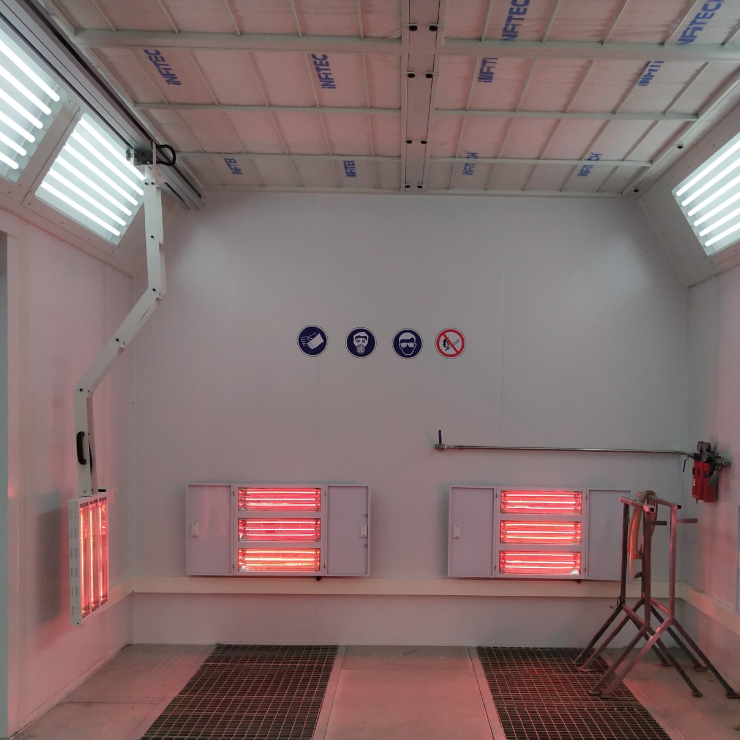

CEILING LIGHTING

|

|

|

Quantity and power

|

8 sets of light fixtures, each 4 x 24W, 768W total

|

|

Lighting arrangement

|

On both sides

|

|

Lighting description

|

LED lamp, protection grade IP54

|

|

Brightness

|

>1000Lux

|

|

FILTRATION SYSTEM

|

|

|

Pre-filtration

|

G3 grade pre-filter plate filter

|

|

Ceiling filter

|

F5 class filter cotton, Model SP-600G

|

|

Floor filtration

|

Fiberglass paint arrestor filters

|

|

Exhaust filter

|

Simple activated carbon filter mat, M type

|

|

INTAKE SYSTEM

|

|

|

Intake fan

|

Direct-type turbine fan

|

|

Power and motor description

|

5.5KW, 970rpm, 380V, 50Hz, CE approved motor

|

|

Parameter of intake fan

|

22,000m3/h, 600pa

|

|

EXHAUST SYSTEM

|

|

|

Exhaust fan

|

Direct-type turbine fan

|

|

Power and motor description

|

5.5KW, 970rpm, 380V, 50Hz, CE certified motor

|

|

Parameter of exhaust fan

|

22,000m3/h, 600pa

|

|

Empty loaded air speed

|

+/- 0.22m/s

|

|

NOISE

|

<78dB

|

|

HEATING SYSTEM

|

|

|

Heating form

|

Diesel heating

|

|

Power and quantity

|

158KW

|

|

Heat exchanger material

|

Stainless steel 1Gr18Ni9Ti (SUS304)

|

|

△T temperature increase capability

|

20° C (from 0°C to 20°C, in painting phase)

|

|

Max. working temperature

|

80° C

|

|

Heating time

|

6-10 minutes (from 20°C to 60°C, in baking phase)

|

|

Burner model

|

REILLO diesel burner G20 (one stage)

|

|

DUCTWORK

|

|

|

Straight ducting

|

4 pcs, for air outlet

|

|

90° elbow

|

1 pc, for air outlet

|

|

45°elbow

|

1 pc, for air outlet

|

|

Reducer

|

1 pc

|

|

CONTROL SYSTEM

|

|

|

Implementation standard

|

Direct start

|

|

PLC programmable logic controller

|

PLC control, higher reliability, lower failure rate

|

|

Touch screen control system

|

User friendly interface featuring touch screen and switches, easy to operate

|

|

Features

|

Painting, heating painting, baking, lighting, emergency stop switch, failure indication, over-temperature alarm indication, motor

over-load and over-current protection

|

|

RATED POWER

|

13KW

|

|

OPTION

|

1. Full grids

2. Adding the sidewall lighting

3.Add water soluble device

4.Infrared lamp heating /gas heating or others

5.Add sliding hanging rack

|